Synchronous electrocatalytic oxidation-reduction degradation reactor and method for treating membrane filtration concentrated solution

An electrocatalytic oxidation and degradation reactor technology, applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc., can solve problems such as increasing operating costs, degradation efficiency of refractory organic matter, and reducing salt content in sewage , to achieve the effect of improving the oxidation activity of the electrode, facilitating catalytic degradation, and simplifying the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

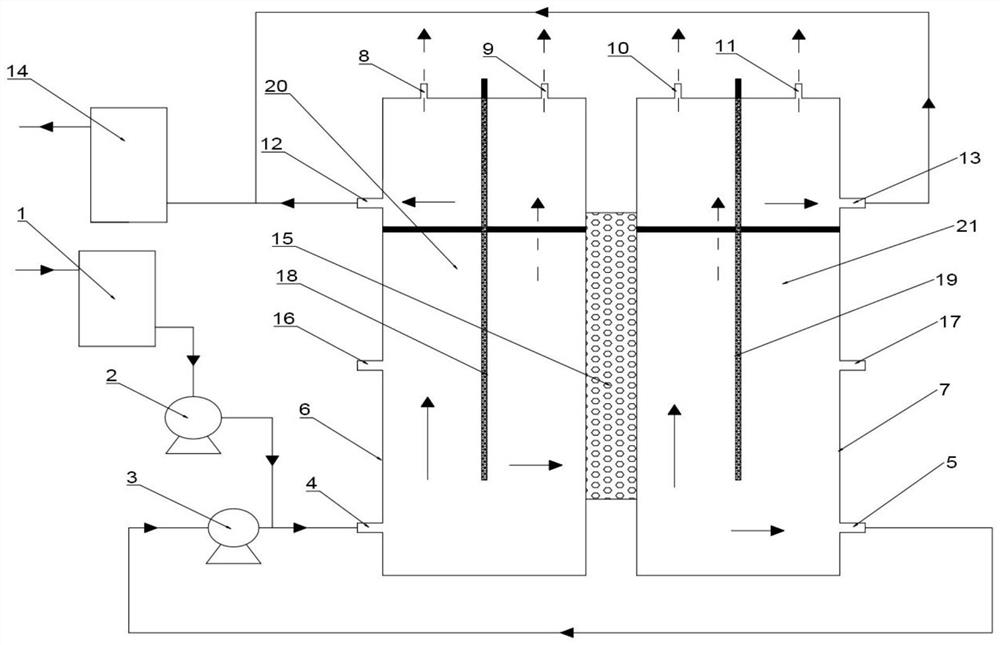

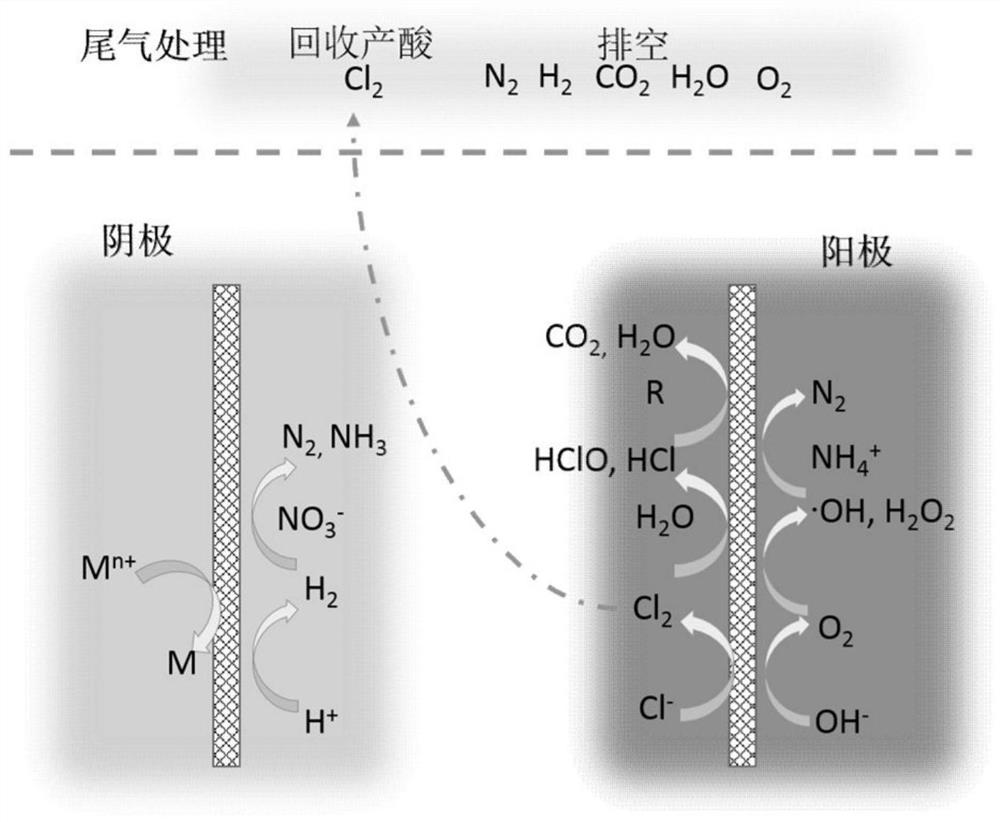

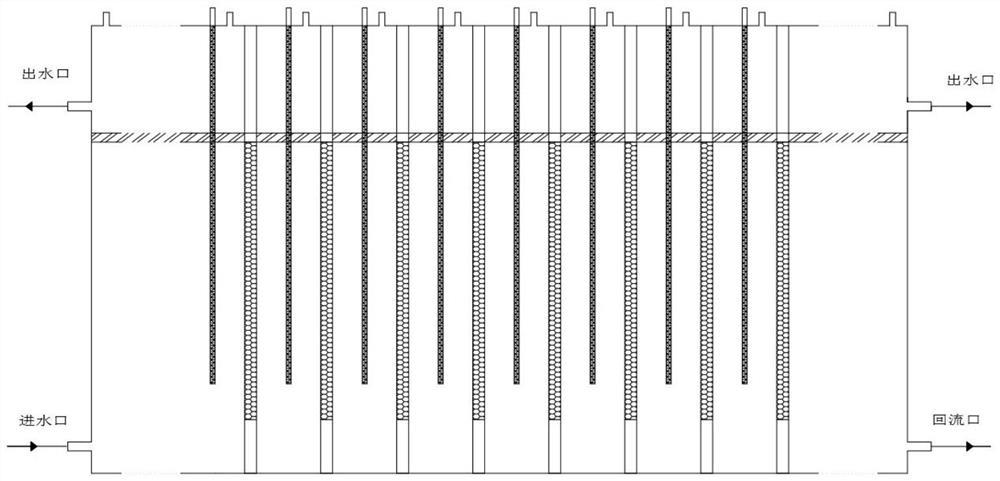

[0040] Such as figure 1 As shown, a synchronous electrocatalytic oxidation-reduction degradation reactor includes an anode chamber 6 and a cathode chamber 7, the anode chamber 6 and the cathode chamber 7 are alternately arranged, and a porous partition is arranged between the anode chamber 6 and the cathode chamber 7 Plate 15, an anode 18 is provided in the anode chamber 6, and a cathode 19 is provided in the cathode chamber 7.

[0041] In this embodiment, the anode 18 is based on a mesh electrode plate or a foam electrode plate (titanium mesh or titanium plate), and the surface of the base material is coated with an anode active material, and the anode active material is an oxide of ruthenium, iridium, or tantalum. at least one of the Specifically: the substrate is a titanium mesh, and the anode active material is a mixture of ruthenium dioxide / iridium dioxide (RuO 2 -IrO 2 ), wherein the mass ratio of ruthenium dioxide and iridium dioxide in the mixture of ruthenium dioxi...

Embodiment 2

[0070] A method for treating the membrane filtration concentrate, using the synchronous electrocatalytic oxidation-reduction degradation reactor in Example 1 to process the membrane filtration concentrate, specifically: adopting the treatment method of oxidation degradation first and then reduction degradation, including the following step:

[0071] S1, adopt continuous batch type water intake, pass the membrane filtration concentrate of 15L of a leachate treatment plant of a domestic waste landfill in Changsha City into the anode chamber 6 and the cathode of the synchronous electrocatalytic oxidation-reduction degradation reactor of embodiment 1 In chamber 7, the membrane filter concentrated solution is oxidatively degraded first, and then the oxidatively degraded membrane filter concentrated solution is reduced and degraded, wherein the current density during the oxidative degradation process is 50mA / cm 2 , the oxidative degradation time is 15min; the current density during ...

Embodiment 3

[0079] A method for treating the membrane filtration concentrate, using the synchronous electrocatalytic oxidation-reduction degradation reactor in Example 1 to process the membrane filtration concentrate, specifically: adopting the treatment method of reducing and degrading first, and then oxidizing and degrading, including the following step:

[0080] S1, adopt continuous batch type water intake, pass the membrane filtration concentrate of 15L of a leachate treatment plant of a domestic waste landfill in Changsha City into the anode chamber 6 and the cathode of the synchronous electrocatalytic oxidation-reduction degradation reactor of embodiment 1 In chamber 7, the membrane filter concentrated solution is reduced and degraded first, and then the reduced and degraded membrane filter concentrated solution is oxidatively degraded, wherein the current density during the reduction degradation process is 10mA / cm 2 , the reduction degradation time is 15min; the current density dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com