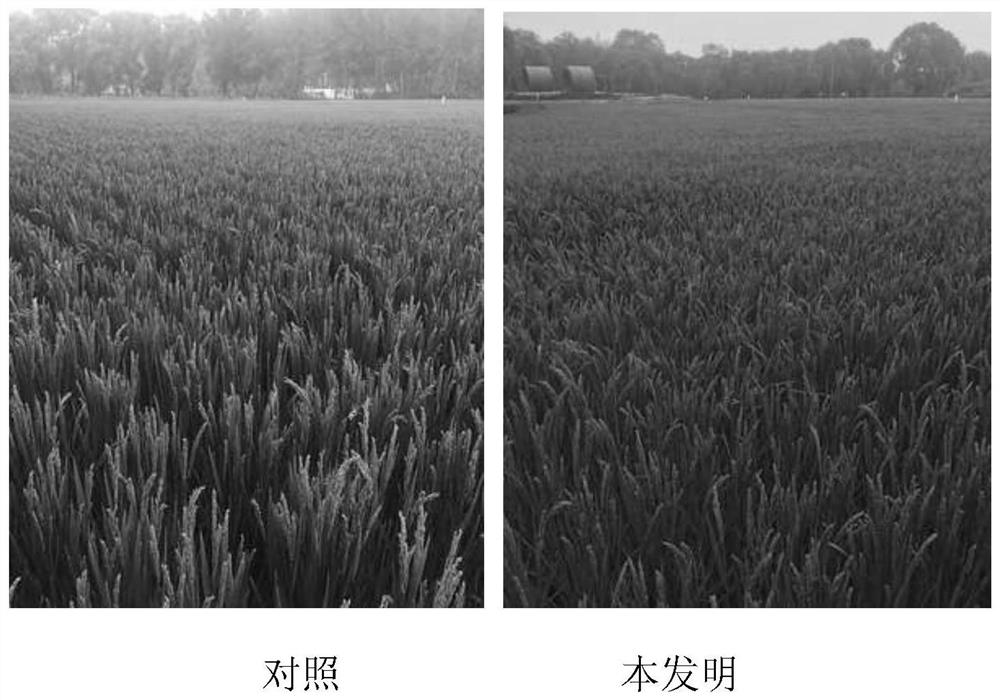

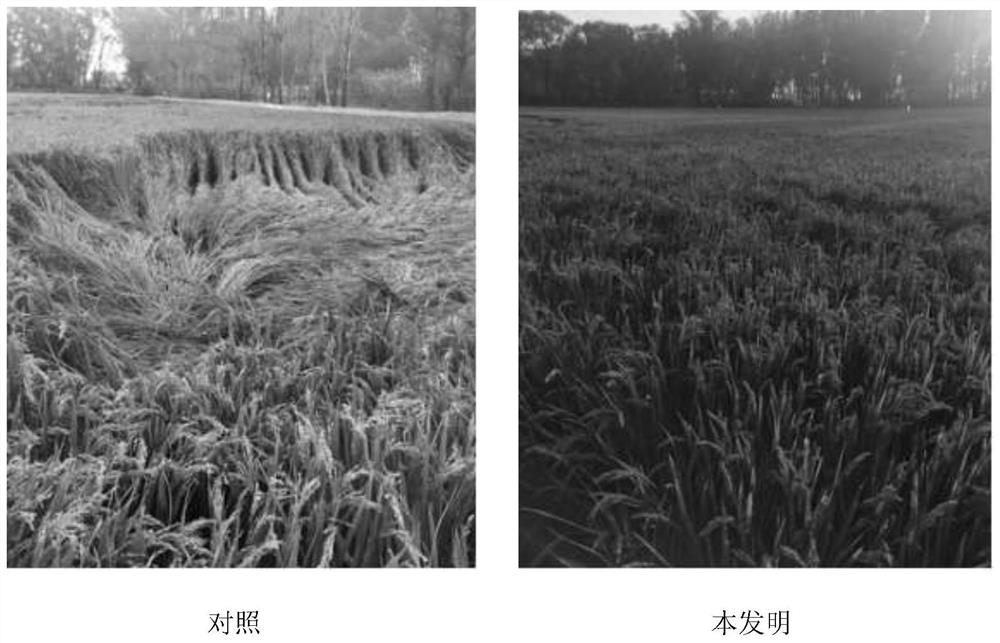

Biostimulant coated compound fertilizer as well as application and preparation method thereof

A technology of biostimulants and compound fertilizers, applied in urea compound fertilizers, layered/coated fertilizers, applications, etc., can solve the problems of soil nutrient ratio imbalance, reduced activity, and slow nutrient release rate, etc., to improve fertilizer nutrients Utilization rate, increase yield and quality, and improve the effect of fertilizer utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1: Preparation 1 of biostimulant-coated compound fertilizer:

[0036] a. Preparation of biostimulant coating agent: dissolve 10kg of water-soluble coating agent in 90kg of warm water, keep the heating temperature above 30°C, add 1kg of seaweed oligosaccharide solution (seaweed oligosaccharide is above 18%), 1kg of rhizosphere Growth-promoting bacteria (PGPR), fully stirred for 10min, then added 0.8kg cellobiolipid fermentation liquid (cellobiolipid content is more than 50g / L), 0.2kg rhamnolipid fermentation liquid (rhamnolipid content 60g / L above) and stirred for 10 minutes, the biostimulant coating agent was prepared and kept warm at 30°C for use.

[0037] b. Grind and sieve the fermented organic fermented material (chicken manure: duck manure: reed straw composted at 6:1:3) and other raw materials respectively, and according to the following weights: 50kg of organic fermented material, 18kg of Urea, 12kg of monoammonium phosphate, 10kg of potassium chloride...

Embodiment 2

[0038] Embodiment 2: Preparation two of biostimulant coated compound fertilizer:

[0039] a. Preparation of biostimulant coating agent: Dissolve 10kg of water-soluble coating agent in 90kg of warm water, keep the heating temperature above 30°C, add 1kg of polyglutamic acid, 1kg of rhizosphere growth-promoting bacteria (PGPR), and fully stir After 10 minutes, add 1 kg of cellobiolipid fermentation liquid (with a cellobiolipid content of 50 g / L or more), and stir for 10 minutes to prepare the biostimulant coating agent, which is kept warm at 30°C until use.

[0040] b. Grind and sieve the fermented organic fermented material (chicken manure: cow dung: reed straw composted at 7:1:2) and other raw materials respectively, and use the following weights: 40kg of organic fermented material, 11kg of urea , 30kg of monoammonium phosphate, 9kg of potassium chloride, 0.5kg of potassium octaborate tetrahydrate, and 10kg of clay are fed into the corresponding feeding bins respectively, and ...

Embodiment 3

[0041] Embodiment 3: Preparation three of biostimulant-coated compound fertilizer:

[0042] a. Preparation of biostimulant coating agent: dissolve 10kg water-soluble coating agent in 90kg warm water, keep the heating temperature above 30°C, add 1kg seaweed oligosaccharide (seaweed oligosaccharide content is more than 18%), 0.5kg polysaccharide Glutamic acid, 1kg rhizosphere growth-promoting bacteria (PGPR), fully stirred for 10min, then added 0.8kg cellobioglycolipid fermentation broth (more than 50g / L cellobiolipid content), 0.2kg trehalolipid fermentation broth ( Trehalolipid content of 50 g / L or more), stirring for 10 minutes, the biostimulant coating agent is prepared, and kept warm at 30°C for use.

[0043] b. Fermented organic fermented material (chicken manure: pig manure: corn stalk is 6:2:2 composting) and other raw materials are crushed and sieved respectively, and according to the organic fermented material that the weight fraction is 35%, 45% % urea, 10% potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com