Preparation method of catalyst material for catalytic oxidation treatment of ammonia-containing waste gas

A catalytic oxidation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as poor catalytic performance, improve diffusion and transfer limits, increase The effect of stable performance and large catalytic specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

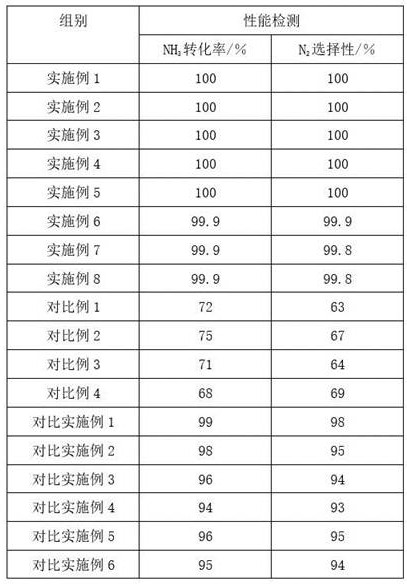

Examples

preparation example 1

[0037] Weigh 45g of deionized water, 6g of 0.5mol / L sulfuric acid, 10g of 0.1mol / L HCl, 15g of 15% copper sulfate solution, and 1g of phenolsulfonic acid in a stirring device, stir and mix them and let stand for 6 hours to obtain electroplating Liquid 1;

[0038] Weigh 45g of deionized water, 15g of 10% solid content silica sol, 3g of aluminum isopropoxide and 1g of phosphoric acid and stir and mix respectively to obtain a mixed solution and mix tetraethylammonium hydroxide, di n-Propylamine and the mixed solution were stirred and mixed, and treated in an oil bath at 45° C. for 3 hours, left to cool and collected to obtain coating solution 1 .

preparation example 2

[0040] Weigh 47g of deionized water, 7g of 0.5mol / L sulfuric acid, 12g of 0.1mol / L HCl, 17g of 15% copper sulfate solution, and 1g of phenolsulfonic acid in a stirring device, stir and mix and let it stand for 7 hours to obtain electroplating Liquid 2;

[0041] Weigh 47g of deionized water, 17g of 10% solid content silica sol, 4g of aluminum isopropoxide and 1g of phosphoric acid and stir and mix respectively to obtain a mixed solution and mix tetraethylammonium hydroxide, di n-Propylamine and the mixed solution were stirred and mixed, placed in an oil bath at 50°C for 4 hours, cooled and collected to obtain coating solution 2.

preparation example 3

[0043] Weigh 50g of deionized water, 8g of 0.5mol / L sulfuric acid, 15g of 0.1mol / L HCl, 20g of 15% copper sulfate solution, and 2g of phenolsulfonic acid in a stirring device, stir and mix and let it stand for 8 hours to obtain electroplating Liquid 3;

[0044] Weigh 50g of deionized water, 20g of silica sol with a solid content of 10%, 5g of aluminum isopropoxide and 2g of phosphoric acid and stir and mix respectively to obtain a mixed solution and mix tetraethylammonium hydroxide, di n-Propylamine and the mixed solution were stirred and mixed, and treated in an oil bath at 55° C. for 5 hours, cooled and collected to obtain the coating solution 3 .

[0045] Preparation example 3

[0046] Weigh 45g of deionized water, 6g of 0.5mol / L sulfuric acid, 10g of 0.1mol / L HCl, 15g of 15% nickel sulfate solution, and 1g of phenolsulfonic acid in a stirring device, stir and mix them and let stand for 6h to obtain electroplating Liquid 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com