Method for detecting content of calcium in solid-core calcium wire

A detection method and technology for calcium content, applied in the field of metallurgical chemical detection and analysis, can solve the problems of cumbersome operation steps and long time-consuming, and achieve the effects of reasonable process, reduced interference, and convenient end point judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

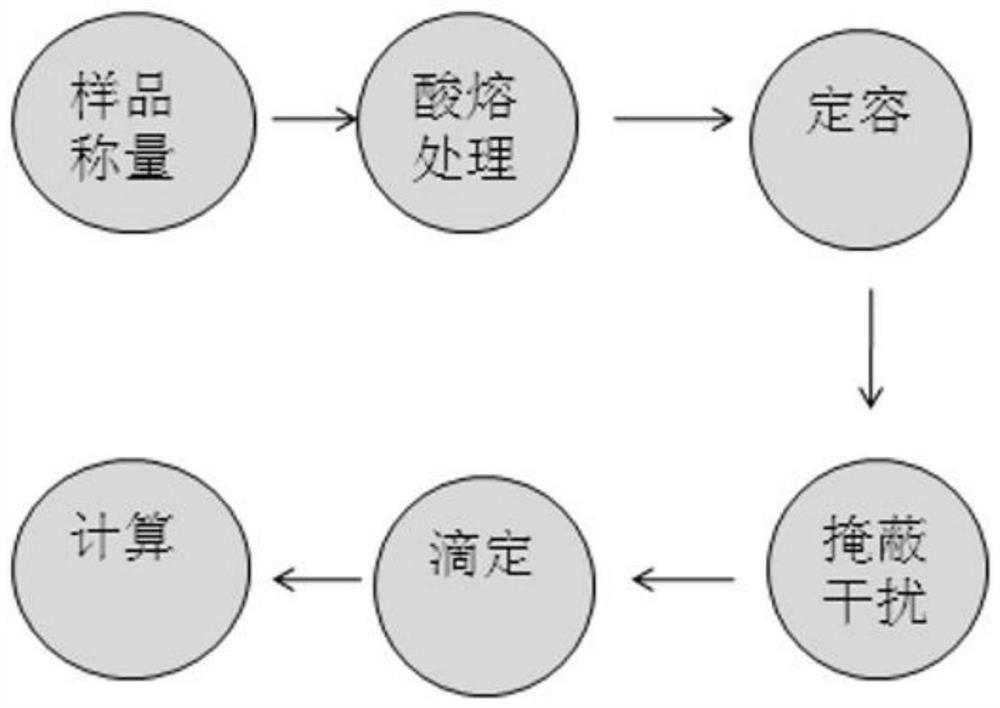

Method used

Image

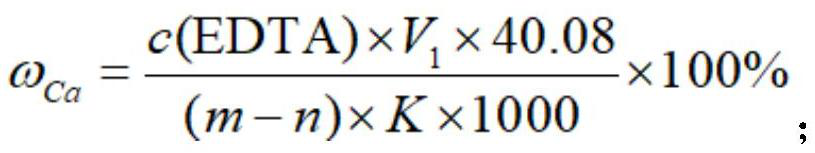

Examples

Embodiment 1

[0045] Embodiment 1 A kind of detection method of calcium content in solid core calcium wire

[0046] 1. Main instruments and equipment

[0047] Balance, electric furnace, box-type resistance furnace.

[0048] 2. Chemical reagents

[0049] (1) hydrochloric acid (ρ1.19g / mL analytically pure);

[0050] (2) Glacial acetic acid (p1.05g / mL analytically pure);

[0051] (3) Anhydrous alcohol (analytical pure);

[0052] (4) Triethanolamine (1+1)

[0053] (5) potassium hydroxide solution (200g / L);

[0054] (6) Calcein indicator: Grind 0.2g of calcein, 0.12g of thymolphthalein, and 20g of anhydrous potassium sulfate in a mortar, dry it in an oven at 105°C-110°C for 1 hour, cool it and move it into a ground glass bottle , stored in a desiccator.

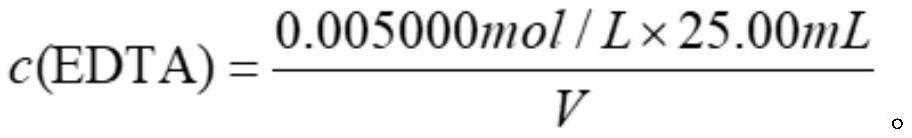

[0055] (7) Calcium standard solution (0.005mol / L): Weigh the standard calcium carbonate (CaCO 3 ≥99.99%) 0.2502g, add 20mL of hydrochloric acid (1+1), heat to dissolve until clear, boil for a while, cool to room temperature, transfer to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com