Modified high-nickel ternary positive electrode material and preparation method thereof

A high-nickel ternary material, cathode material technology, applied in the direction of positive electrode, active material electrode, electrical components, etc., can solve the problems of poor structural stability, high price, affecting battery cycle performance, etc., to achieve good mechanical properties and Solvent resistance, improving comprehensive electrical properties, and solving the problem of high residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention provides a method for preparing a modified high-nickel ternary positive electrode material, comprising the following steps:

[0039] Provide high nickel ternary materials;

[0040] Obtain a modified high-nickel ternary positive electrode material: After vacuum dehydration, the macromolecular polyol and diisocyanate are mixed, and then slowly add the first chain extender and crosslinking agent to it, and heat up to 60-90°C, and react for 1-4 hours At the same time, after adding a solvent to adjust the viscosity during the reaction, slowly add the second chain extender and the high-nickel ternary material, continue to react at 40-80°C for 1-4 hours, and dry to obtain a modified high-nickel ternary material. Yuan cathode material. Wherein, the vacuum dehydration of the macromolecular polyol is not particularly limited, and preferably, the vacuum dehydration is carried out at 80-120°C.

[0041] The invention innovatively uses the...

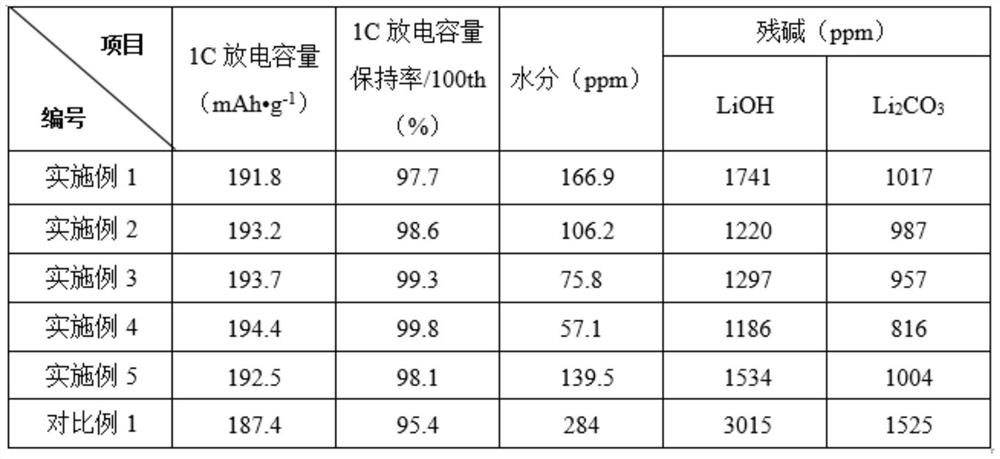

Embodiment 1

[0055] In this embodiment, the preparation steps of the modified high-nickel ternary positive electrode material are as follows:

[0056] Provide high-nickel ternary materials, and weigh the high-nickel ternary precursor Ni according to the ratio of substance amount 1:1.03 0.85 co 0.10 mn 0.05 (OH) 2 and lithium hydroxide, mixed evenly in a 3D mixer, placed in a high-temperature furnace at a rate of 12°C / min in an oxygen atmosphere to heat up to 760°C for 16 hours, and naturally cooled to below 80°C after the heat preservation was completed, that is High nickel ternary material LiNi 0.85 co 0.10 mn 0.05 o 2 .

[0057] Obtain the modified high-nickel ternary positive electrode material: add 20g of spare polypropylene carbonate diol and 1.8g of toluene diisocyanate after vacuum dehydration in a four-necked flask equipped with a polytetrafluoroethylene stirring rod, a spherical condenser and a thermometer, After stirring evenly, slowly add 1.64g of 1,4-butanediol and 0.41...

Embodiment 2

[0059] In this embodiment, the preparation steps of the modified high-nickel ternary positive electrode material are as follows:

[0060] Provide high-nickel ternary material: the steps are the same as in Example 1.

[0061] Obtain the modified high-nickel ternary positive electrode material: add 20g of polyhexamethylene carbonate glycol and 2.14g of polyhexamethylene carbonate glycol and 2.14g of 4, 4'-diphenylmethane diisocyanate, after stirring evenly, slowly add 1.83g of 1,4-butanediol and 0.49g of trimethylolpropane, raise the temperature to 82°C for 2.5h; add 2.5g of N-formazol during the reaction base pyrrolidone, then slowly add 0.151g dimethylolpropionic acid and 1397.3g high-nickel ternary material, raise the temperature to 64°C, continue the reaction for 1.5h, and spray dry to obtain the modified LiNi 0.85 co 0.10 mn 0.05 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com