Solid-phase microextraction probe and preparation method thereof

An extraction and modification technology, applied in the field of analytical chemistry, can solve the problems of low preparation efficiency, cumbersome process and long time, and achieve the effect of fast speed and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a functionalized solid-phase microextraction probe based on alkenyl-modified graphene-nanometer siloxane polymer coating is as follows:

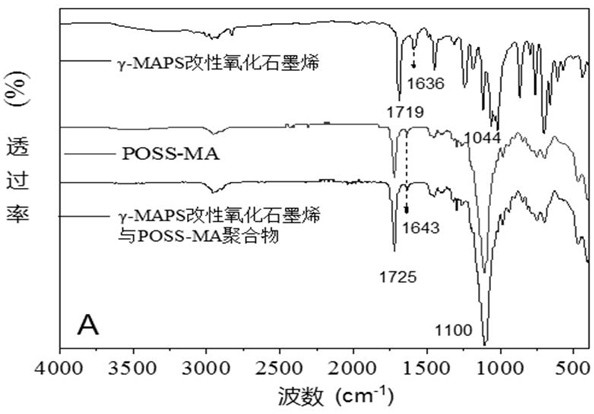

[0029] (1) Disperse 100 mg of graphene oxide GO in deionized water (100 mL) under the action of ultrasound, and sonicate for 1 h; Added dropwise into the above GO solution within 0.5 h under the same conditions, and continued to mechanically stir at 25 °C for 24 h to prepare alkenyl-functionalized γ-MAPS@GO;

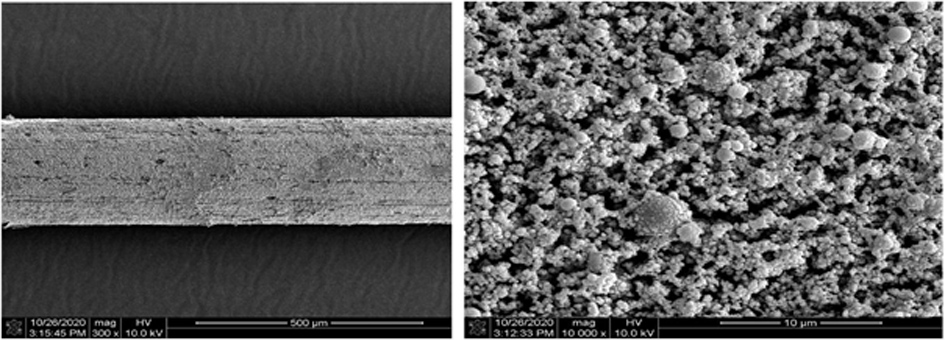

[0030] (2) The stainless steel wire was treated with hydrofluoric acid at 70 °C for 5 min to form a rough surface, and then deionized water, ethanol, and deionized water were treated in an ultrasonic machine for 15 min each and dried naturally; 0.340 g AgNO 3 and 1.980g of glucose were each dissolved in 10 mL of distilled water, in AgNO 3 Add 28% ammonia water dropwise to the solution to form Ag 2 O precipitation, continue to drop 2.8% ammonia water until the precipitation is completely dissolved, add g...

Embodiment 2

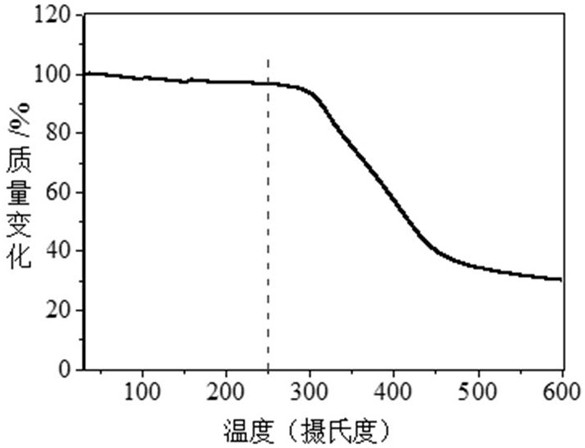

[0040] Formulas A to F in Table 1 were used to prepare alkenyl-modified graphene-nanosiloxane polymer coating functionalized solid-phase microextraction probes to adsorb and desorb polycyclic musk PCMs in environmental water, respectively. The steps are: (1) Aging: Before use, the fiber was aged at the gas chromatograph inlet at 250 °C for 0.5 h; (2) Adsorption: 10 mL of PCMs solution was injected into a 20 mL headspace bottle, and heated at 75 °C Equilibrate for 5 min; pass the fiber in the SPME device through the septum, and expose it to steam at 75 °C for 50 min; (3) Desorption: quickly remove the fiber and insert it into the GC-MS inlet, and perform 5 min at 250 °C Min thermal analysis, using GC-MS detection to collect PCMs.

[0041] Such as Figure 5 , a single caged polysiloxane polymer has poor retention of PCMs, modified graphene oxide has improved retention of PCMs, and γ-MAPS@GO / POSS-MA (Formulation B) has a significant retention of PCMs Improvement, indicating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com