MOF-derived Pt1@CeO2 monatomic catalyst as well as preparation method and application thereof

A technology of catalysts and supported catalysts, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., which can solve problems such as complex preparation process, unfavorable catalyst application and characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.12wt%Pt 1 @CeO 2 Preparation of single-atom catalysts

[0029] Weigh 0.953g cerium amine nitrate and dissolve it in 2.3mL water, then weigh 0.282g terephthalic acid and dissolve it in 9.6mL N,N-dimethylformamide solution, after ultrasonic dissolution, mix the two solutions evenly, add 1.3 mLH 2 PtCl 6 solution (7.4mgPt / ml), heated and stirred in an oil bath at 100°C for 20min, then filtered the solution, washed three times with N,N-dimethylformamide, water, and ethanol, and then put the sample Dry in an oven at 60°C to obtain the Pt@UiO-66(Ce) material. After grinding, the Pt@UiO-66(Ce) sample was transferred to a tube furnace, raised to a pyrolysis temperature of 600°C at a heating rate of 5°C / min, and pyrolyzed in an air atmosphere for 5h, and then cooled naturally to obtain Pt@CeO 2 precursor. Subsequently, the dried precursor was transferred into a tube furnace under 10% H 2 / Ar atmosphere at 300 ° C for reduction, the heating rate is 2 ° C / min, after re...

Embodiment 2

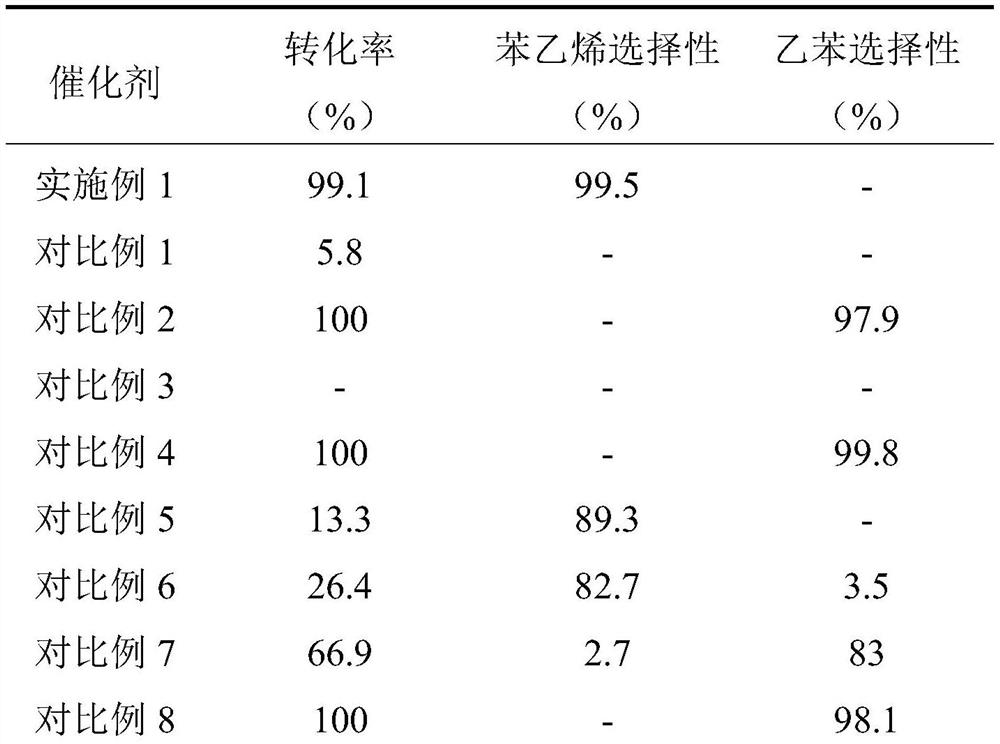

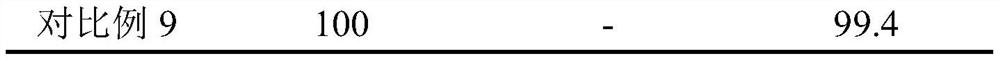

[0058] The above-mentioned 0.12wt%Pt prepared in Example 1 1 @CeO 2 The single-atom catalyst is used to catalyze the selective hydrogenation of phenylacetylene to prepare styrene. First, take the catalyst and 2mL toluene in a 10mL autoclave at room temperature, and feed N 2 Replace 3 times, then pass H 2 Replace 3 times, let H 2 The pressure is 2Mpa, put the reaction kettle into the water bath, turn on the stirring, when the temperature of the water bath rises to 60°C, start the reaction, after 6 hours of reaction, cool down, take an appropriate amount of the reaction solution and centrifuge, and perform gas chromatography analysis.

Embodiment 3

[0060] The 0.02wt%Pt prepared in the above comparative example 1 1 @CeO 2 The single-atom catalyst is used to catalyze the selective hydrogenation of phenylacetylene to prepare styrene. First, take the catalyst and 2mL toluene in a 10mL autoclave at room temperature, and feed N 2 Replace 3 times, then pass H 2 Replace 3 times, let H 2 The pressure is 2Mpa, put the reaction kettle into the water bath, turn on the stirring, when the temperature of the water bath rises to 60°C, start the reaction, after 6 hours of reaction, cool down, take an appropriate amount of the reaction solution and centrifuge, and perform gas chromatography analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com