Nickel diselenide/indium zinc sulfide composite photocatalyst as well as preparation method and application thereof

A technology of composite light and catalyst, applied in the field of photocatalytic materials, can solve the problems of limited wide application and expensive precious metal, and achieve the effects of strong controllability, simple steps and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

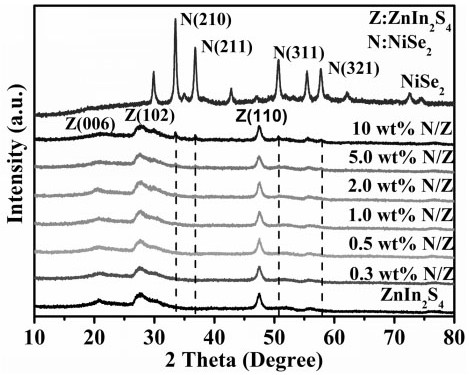

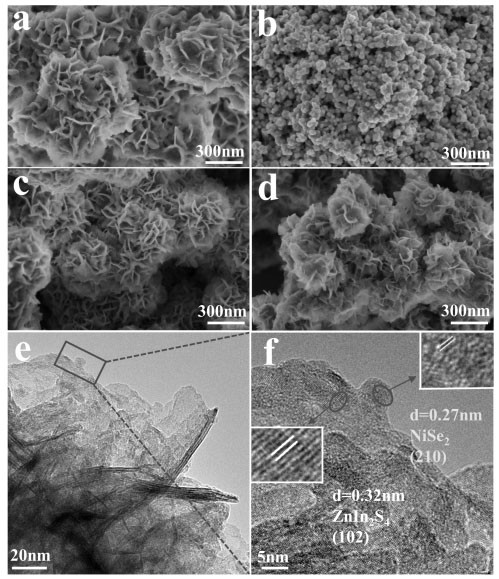

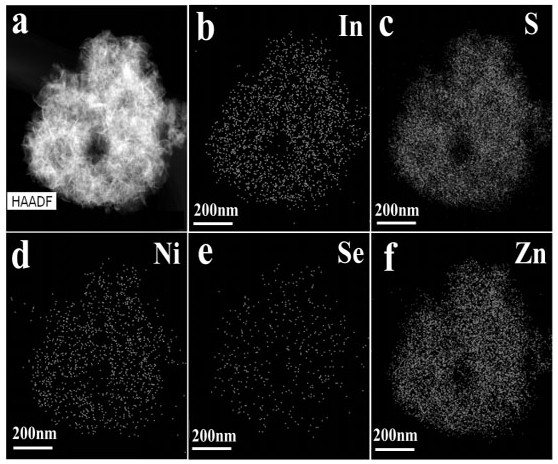

Image

Examples

preparation example Construction

[0028] The preparation steps of the present invention are as follows:

[0029] (1) Preparation of zero-dimensional NiSe by hydrothermal method 2 nanoparticles

[0030]0.228 g of selenium powder and 2.857 g of sodium hydroxide were dissolved in 25 mL of deionized water and stirred. The mixed solution was transferred to an autoclave and reacted at a constant temperature of 180 °C for 12 h. The resulting solution was NaHSe solution.

[0031] Dissolve nickel nitrate hexahydrate (0.1 mmol), sodium citrate (0.1 mmol), and cyclohexamethylenetetramine (0.25 mmol) in 40 mL of deionized water and stir for 30 min, then transfer the mixed solution to an autoclave React at a constant temperature of 120 °C for 12 h. After cooling, NaHSe solution was added to it, and the mixed solution was transferred to an autoclave to react at a constant temperature of 140 °C for 12 h, then cooled to room temperature naturally, and the obtained precipitate was washed with deionized water several times an...

Embodiment 1

[0036] (1) Preparation of zero-dimensional NiSe by hydrothermal method 2 nanoparticles

[0037] 0.228 g of selenium powder and 2.857 g of sodium hydroxide were dissolved in 25 mL of deionized water and stirred. The mixed solution was transferred to an autoclave and reacted at a constant temperature of 180 °C for 12 h. The resulting solution was NaHSe solution.

[0038] Dissolve nickel nitrate hexahydrate (0.1 mmol), sodium citrate (0.1 mmol), and cyclohexamethylenetetramine (0.25 mmol) in 40 mL of deionized water and stir for 30 min, then transfer the mixed solution to an autoclave React at a constant temperature of 120 °C for 12 h. After cooling, NaHSe solution was added to it, and the mixed solution was transferred to an autoclave to react at a constant temperature of 140 °C for 12 h, then cooled to room temperature naturally, and the obtained precipitate was washed with deionized water several times and then dried to obtain NiSe 2 powder.

[0039] (2) Preparation of 0D / 2...

Embodiment 2

[0042] (1) Preparation of zero-dimensional NiSe by hydrothermal method 2 nanoparticles

[0043] 0.228 g of selenium powder and 2.857 g of sodium hydroxide were dissolved in 25 mL of deionized water and stirred. The mixed solution was transferred to an autoclave and reacted at a constant temperature of 180 °C for 12 h. The resulting solution was NaHSe solution.

[0044] Dissolve nickel nitrate hexahydrate (0.1 mmol), sodium citrate (0.1 mmol), and cyclohexamethylenetetramine (0.25 mmol) in 40 mL of deionized water and stir for 30 min, then transfer the mixed solution to an autoclave React at a constant temperature of 120 °C for 12 h. After cooling, NaHSe solution was added to it, and the mixed solution was transferred to an autoclave to react at a constant temperature of 140 °C for 12 h, then cooled to room temperature naturally, and the obtained precipitate was washed with deionized water several times and then dried to obtain NiSe 2 powder.

[0045] (2) Preparation of 0D / 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com