Strontium zirconate inorganic fiber and preparation method thereof

A technology of inorganic fiber and strontium zirconate, which is applied in the direction of artificial filaments of inorganic raw materials, can solve the problems of no strontium zirconate fiber, etc., and achieve the effects of easy spinning and mass production, stable sol, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

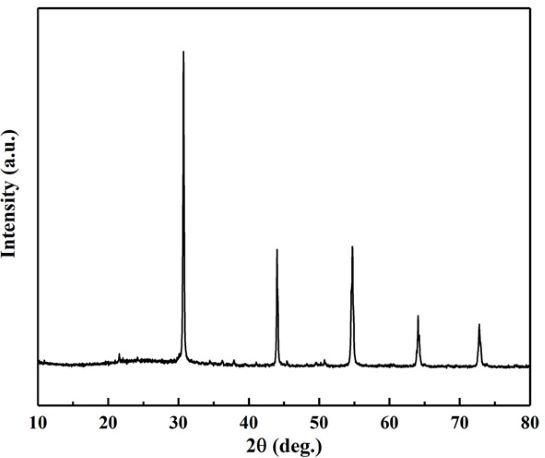

[0033]Preparation method of zirconate inorganic fibers, including the steps of:

[0034](a) Preparation of primary zirconate precursor sol

[0035]Raw zirconium chloride, ice acetic acid according to molar rativation of zirconium chloride: Ice acetic acid = 1: 1.2 to the mass ratio solid: water = 1: 2 water, dissolve the zirconia precursor sol; heating at 60 ° C Under the conditions, molar ratio Zr: Sr = 1: 1 is added to the zirconia precursor sol, and the zirconate sol is dissolved; the mass fraction is added to the zirconate sol, which is 1.5% polyoxyethylene. Make full dissolve zirconate precursor sol;

[0036](b) Straoperate precursor fibers prepared by static spinning method

[0037]The zirconate precursor sol of step (a) is bleedr-zirconate precursor fibers by electrostatic spinning, wherein the electrospinning process conditions are a spinning distance of 16cm, and the spinning voltage is 16 kV, and the sol propulus rate is 2.0 mL / H, the ambient temperature is 10 ~ 25 ° C, the environm...

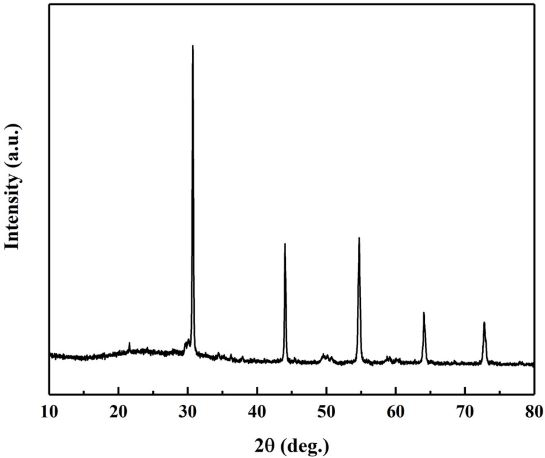

Embodiment 2

[0041]As described in Example 1, the difference is a cerium carbonate in step (a) to cerium oxide.

Embodiment 3

[0043]As described in Example 1, the difference is to replace the barium carbonate in step (a) to hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com