A kind of lithium cobalt oxide cathode material coated with nanometer cobalt lithium phosphate and preparation method thereof

A technology of lithium cobalt phosphate and positive electrode materials, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of fast capacity decay, poor cycle performance of lithium cobaltate, and poor long-term cycle performance of batteries. The effect of low raw material cost, simple operation process and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

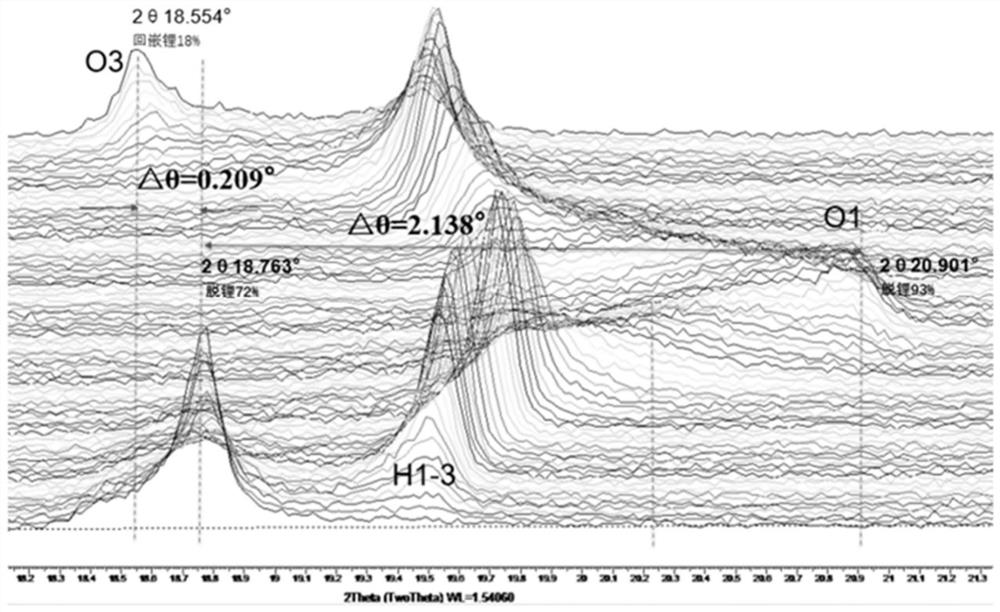

[0039] Example 1: Preparation of lithium cobalt phosphate nanoparticles by wet method, lithium cobalt oxide cathode material of wet method coating of lithium cobalt phosphate nanoparticles

[0040] 1) Preparation of nanometer lithium cobalt phosphate: Weigh lithium carbonate, tricobalt tetroxide, diammonium hydrogen phosphate, basic magnesium carbonate, iron oxalate, the quality of basic magnesium carbonate accounts for 0.01% of lithium cobaltate, and iron oxalate accounts for 0.01% of lithium cobaltate %, pour it into the basket grinder, add grinding balls, the amount of grinding balls is 2 times the total mass of the material, add ethanol, the solid-liquid ratio is 1:2, mix on the basket grinder for 3 hours, and then mix the slurry Transfer to a nanomill, and after 4 hours of grinding, dry on a rake dryer for 2 hours. The mixed materials are calcined in a reducing gas hydrogen gas at 600°C in a muffle furnace, and kept for 6 hours. After calcination, the pellets are pulveri...

Embodiment 2

[0042] Example 2: Preparation of lithium cobalt phosphate nanoparticles by wet method, lithium cobalt oxide cathode material wet coated with lithium cobalt phosphate nanoparticles

[0043] 1) Preparation of nanometer cobalt phosphate: Weigh lithium carbonate, tricobalt tetroxide, diamine hydrogen phosphate, basic magnesium carbonate, titanium dioxide, the quality of basic magnesium carbonate accounts for 0.01% of lithium cobaltate, and titanium dioxide accounts for 0.02% of lithium cobaltate, Pour it into the basket grinder, add grinding balls, the amount of grinding balls is 2 times the total mass of the material, add ethanol, the solid-liquid ratio is 1:2, mix on the basket grinder for 3 hours, and then transfer the slurry to Nanomill, after 4 hours of grinding, dry on a rake dryer for 2 hours. The mixed materials are calcined in a reducing gas hydrogen gas at 600°C in a muffle furnace, and kept for 6 hours. After calcination, the pellets are pulverized and passed through a...

Embodiment 3

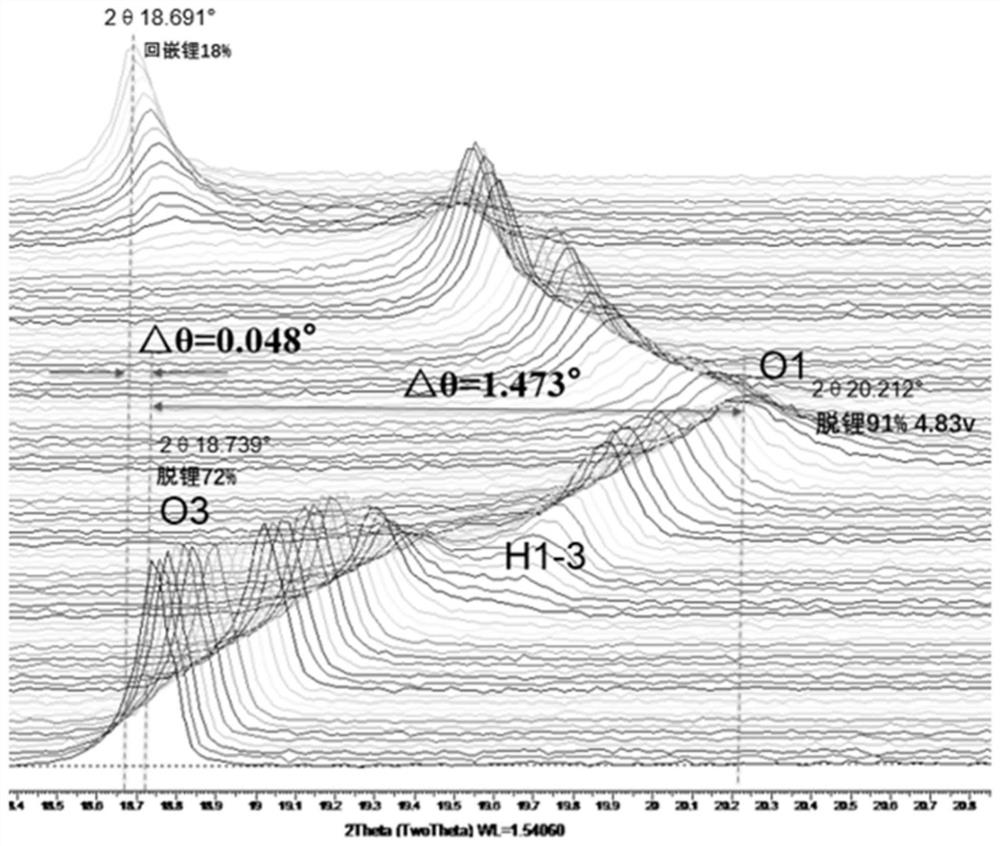

[0047] Example 3: Preparation of Lithium Cobalt Phosphate by Solid Phase Method, Nano-milled Lithium Cobalt Phosphate, Lithium Cobalt Oxide Wet Coating Nanometer Lithium Cobalt Phosphate

[0048] 1) Preparation of nanometer lithium cobalt phosphate: Weigh lithium acetate, tricobalt tetroxide, diamine hydrogen phosphate, magnesium oxide, and vanadium pentoxide. The mass of magnesium oxide accounts for 0.01% of lithium cobalt oxide, and vanadium pentoxide accounts for 0.01% of lithium cobalt oxide. %, pour it into the material tank, add grinding balls, the amount of grinding balls added is twice the total mass of the material, and mix for 3 hours. The mixed materials were calcined in a reducing gas hydrogen gas at 700°C in a muffle furnace, and kept for 6 hours. After calcination, the material block is pulverized and passed through a 300-mesh sieve, poured into a nanometer mill, and ground for 3 hours to obtain nanometer magnesium vanadium doped lithium cobalt phosphate with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com