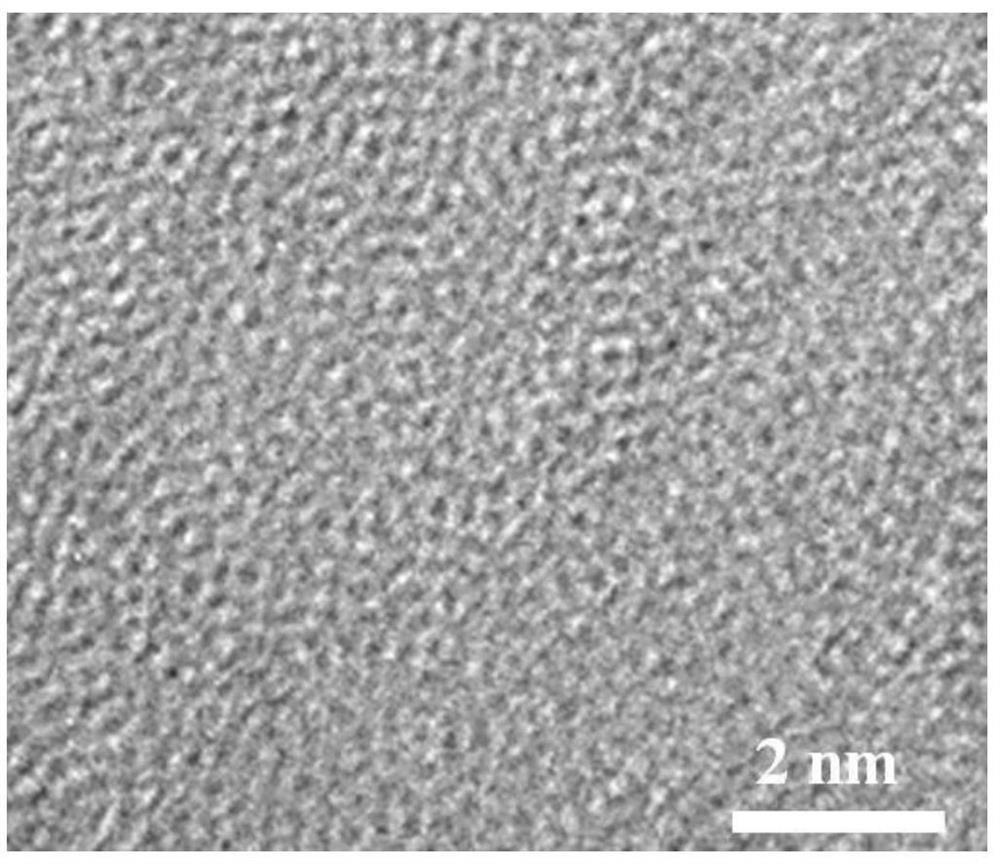

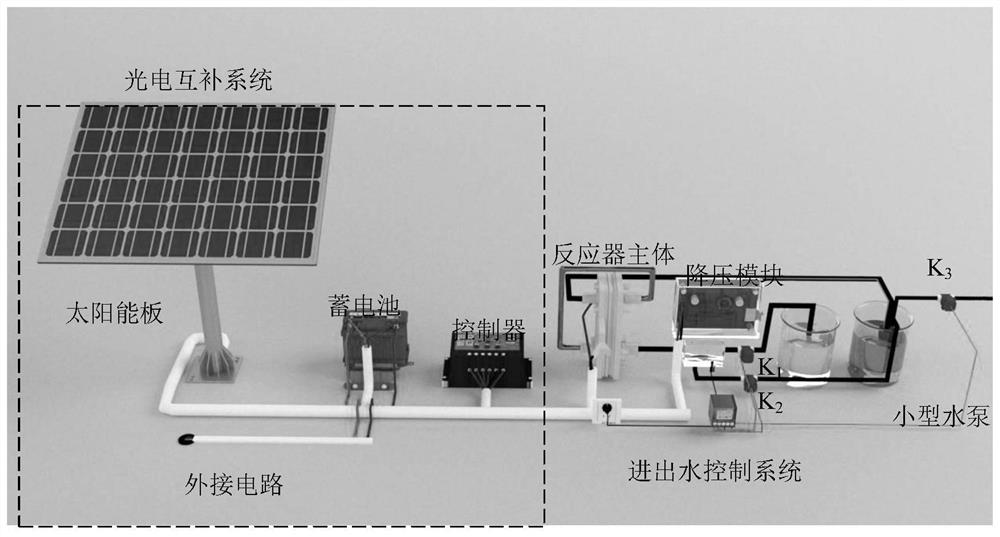

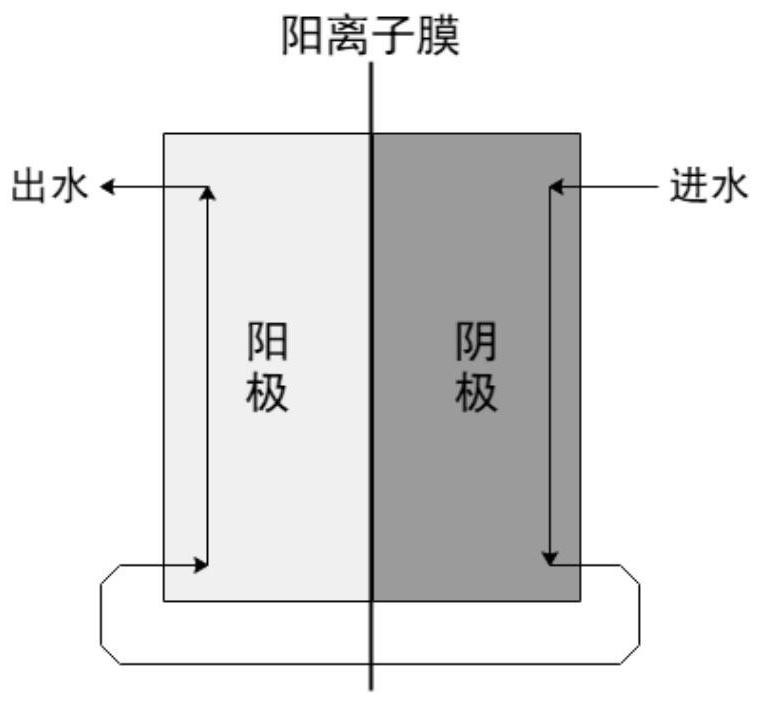

Preparation method and application of three-dimensional Fe-Mo-S catalyst loaded porous carbon electrode

A porous carbon electrode, fe-mo-s technology, applied in carbon preparation/purification, chemical instruments and methods, current collectors, etc., can solve the problems of slow reaction rate, poor treatment effect, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method of preparing a three-dimensional Fe-Mo-S catalyst load, including the following steps:

[0053] 1) First, the cleansing carbon fiber felt (or carbon felt, porous carbon, three-dimensional carbon felt) is soaked in concentrated nitric acid, resulting in an oxygen-containing functional group on the surface of the carbon fiber felt and increase its hydrophilicity, then washing carbon fiber felt Sex

[0054] 2), weigh 0.3475 grams, FESO, respectively 4 · 7h 2 O (seven hydrogen sulfate), 0.3024 g of NA 2 MOO 4 · 2h 2 O (sodium dihydrate) and 1.593 g of L-CYS amino acid (L-cysteine) is dissolved in the reaction kettle liner, ultrasonic and stirred until it is fully dissolved to obtain a clear liquid, and to 200 mL to obtain a solution ;

[0055] 3), transfer the above solution to 300 mL of water heat synthesis reactor in the liner, and placed in washed carbon fiber felt;

[0056] 4) Put the reactor into the electric heating air oven for synthesis, the synthesis temperatu...

Embodiment 2

[0059] A method of preparing a three-dimensional Fe-Mo-S catalyst load, including the following steps:

[0060] 1) First, the clean carbon fiber felt is soaked in concentrated nitric acid to produce oxygen-containing functional groups on the surface of the carbon fiber felt and increase its hydrophilicity, then washed carbon fiber felt to neutral;

[0061] 2), weigh 0.8 grams of FESO, respectively 4 · 7h 2 O (seven hydrated sulfate), 0.6 grams of NA 2 MOO 4 · 2h 2 O (sodium dihydrate) and 3.0 g of L-Cys amino acids are dissolved in the reaction kettle liner, ultrasonic and stirred until the transparent liquid is sufficiently dissolved, and the solution is obtained;

[0062] 3), transfer the above solution to 300 mL of water heat synthesis reactor in the liner, and placed in washed carbon fiber felt;

[0063] 4) Put the reactor into the electric heating air oven for synthesis, the synthesis temperature is 200 ° C, the synthesis time is 24 h, naturally cooled to room temperature aft...

Embodiment 3

[0066] A method of preparing a three-dimensional Fe-Mo-S catalyst load, including the following steps:

[0067] 1) First, the clean carbon fiber felt is soaked in concentrated nitric acid to produce oxygen-containing functional groups on the surface of the carbon fiber felt and increase its hydrophilicity, then washed carbon fiber felt to neutral;

[0068] 2), Weighing 1.0425G FESO, respectively 4 · 7h 2 O (seven hydrogen sulfate), 0.9072G NA 2 MOO 4 · 2h 2 O (sodium dihydrate) and 4.7979 g of L-Cys amino acids are dissolved in the reaction kettle liner, ultrasonic and stirred until the transparent liquid is sufficiently dissolved, and the solution is obtained to obtain a solution;

[0069] 3), transfer the above solution to 300 mL of water heat synthesis reactor in the liner, and placed in washed carbon fiber felt;

[0070] 4) Put the reactor into the electric heating air oven for synthesis, the synthesis temperature is 200 ° C, the synthesis time is 24 h, naturally cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com