Multi-layer core-sheath structure composite filament for energy storage and preparation method of multi-layer core-sheath structure composite filament

A multi-layer structure and composite wire technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve a wide range of application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

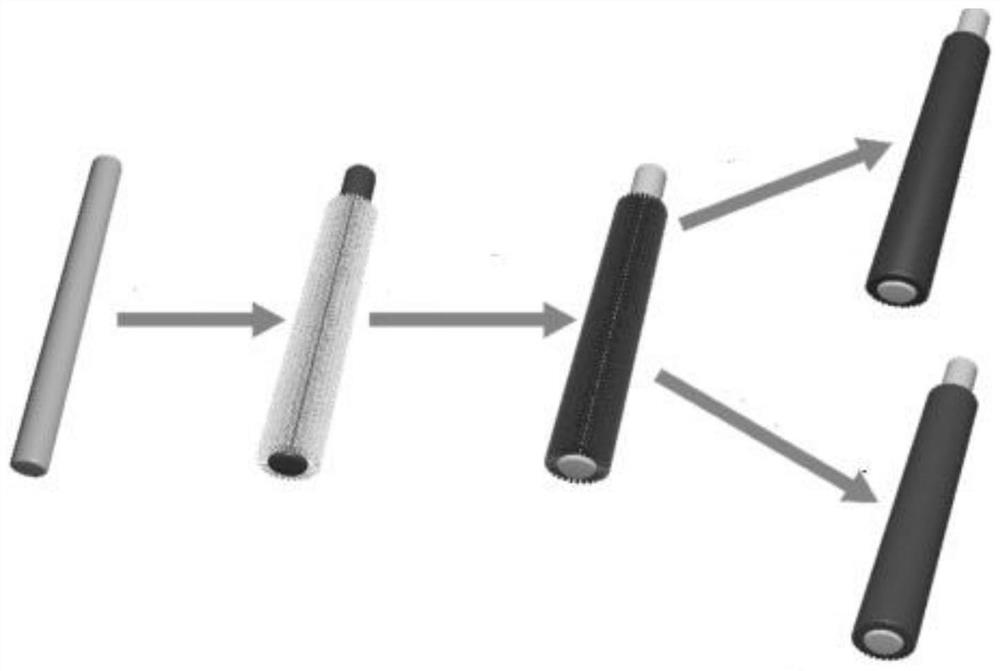

[0032] A method for preparing a multi-hierarchy structure composite wire for energy storage, including the following steps:

[0033] S1, the titanium wire separately washed with the washing liquid, acetone, and clean water, respectively;

[0034] S2, ammonium fluid (NH 4 F) Water and ethylene glycol mixed solution, the molybdenum wire is fixed to the anode, and the oxidation is performed by platinum as a counter electrode, forming TiO. 2 / Ti core sheath structure composite wire;

[0035] S3, the composite wire in step S2 is cleaned with water and ethanol, respectively, and dried;

[0036] S4, will dry the TiO 2 / Ti-core sheath structure composite wire is placed in a tube furnace, under argon protection, by CVD deposition method in TiO 2 / Ti-core sheath structure composite wire surface growth 1 layer of carbon, forming C / TiO 2 / Ti multilayer structure composite wire;

[0037] S5, in C / TiO 2 / Ti multilayer structure composite wire composite wire surface further modifies a h...

Embodiment 1

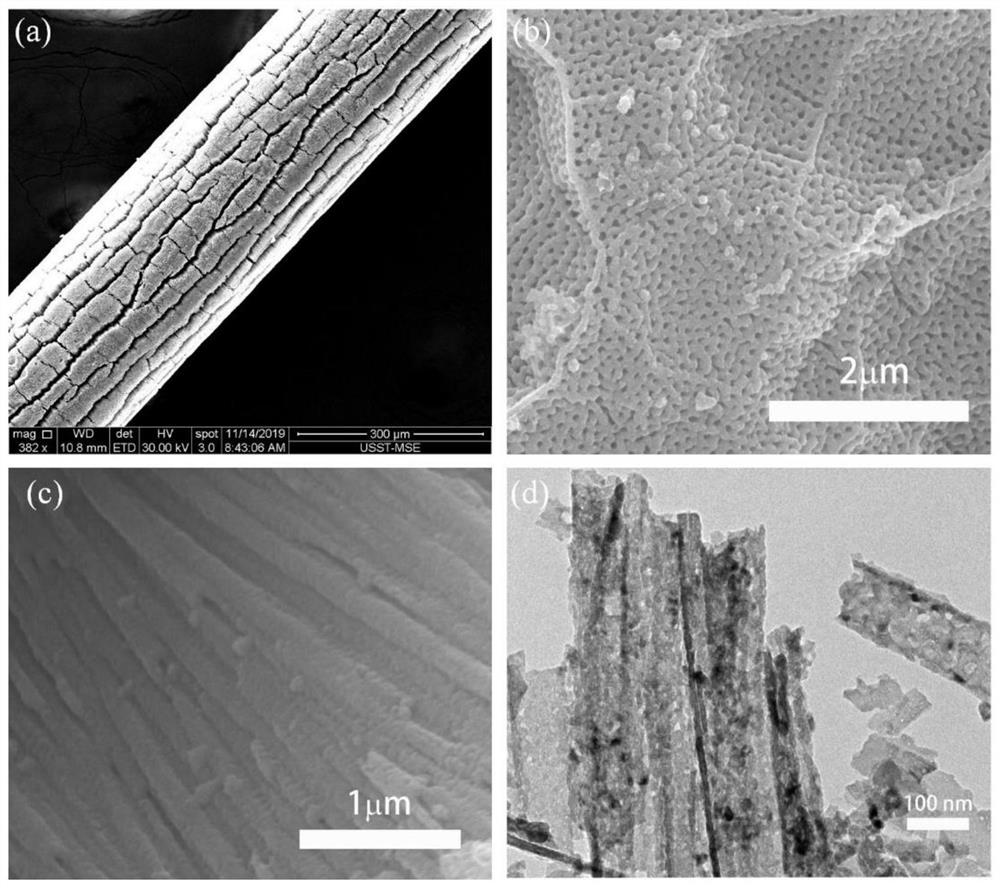

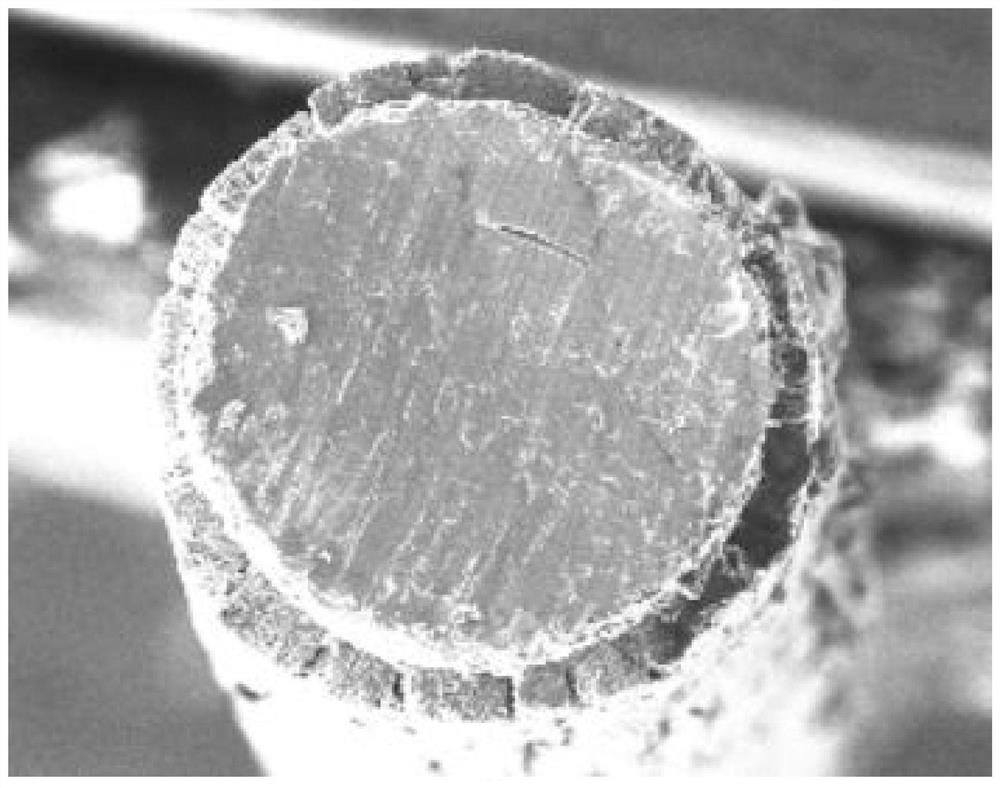

[0046] 2 ml of water and 98 ml of ethylene glycol were mixed, and the water-ethylene glycol mixed solution was used as a water content of 2V%. 0.333 g of ammonium fluid was added to the above mixing solution, which was mounted to a water-ethylene glycol mixed solution containing 0.3 wt% fluorine fluid. In the electrolytic solution in this solution, a 1-row length is 20 cm, and a titanium wire having a diameter of 250 microns is fixed to the anode, and the electrode is used to use a platinum electrode, and the anodization of the anode oxidation is performed at normal temperature. The anode oxidation is 60 V, Time 5 hours, the oxidized titanium oxide / titanium composite wire was taken out and dried.

[0047] The titanium oxide / titanium composite wire was placed in a tubular reactor and warmed up to 650 degrees Celsius under argon protection of 200 SCCM gas flow. After the temperature reached 650 degrees, 10 sccm of hydrogen and acetylene of 20 sccm were introduced and maintained ...

Embodiment 2

[0049] 3 ml of water and 97 ml of ethylene glycol were mixed with a water-ethylene glycol mixed solution of 3 V%. 0.333 g of ammonium fluid was added to the above mixing solution, which was mounted to a water-ethylene glycol mixed solution containing 0.3 wt% fluorine fluid. In the electrolytic solution in this solution, the 1 row length is 20 cm and the diameter of 500 microns is fixed to the anode, and the electrode is used to use a platinum electrode, and the anodization is used for anodizing at normal temperature, and the anode oxidation is constant voltage 60V. At 7 hours, the titanium oxide / titanium composite filament obtained after oxidation was taken out and dried.

[0050] The titanium oxide / titanium composite wire was placed in a tubular reactor and warmed up to 700 degrees Celsius under argon protection of 200 Sccm gas flow. After the temperature reached 700 degrees, 10 SCCM hydrogen and acetylene of 20 sccm were introduced, and the conditions were maintained for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com