Porous carbon/Ni(OH)2 composite electrode material and preparation method thereof

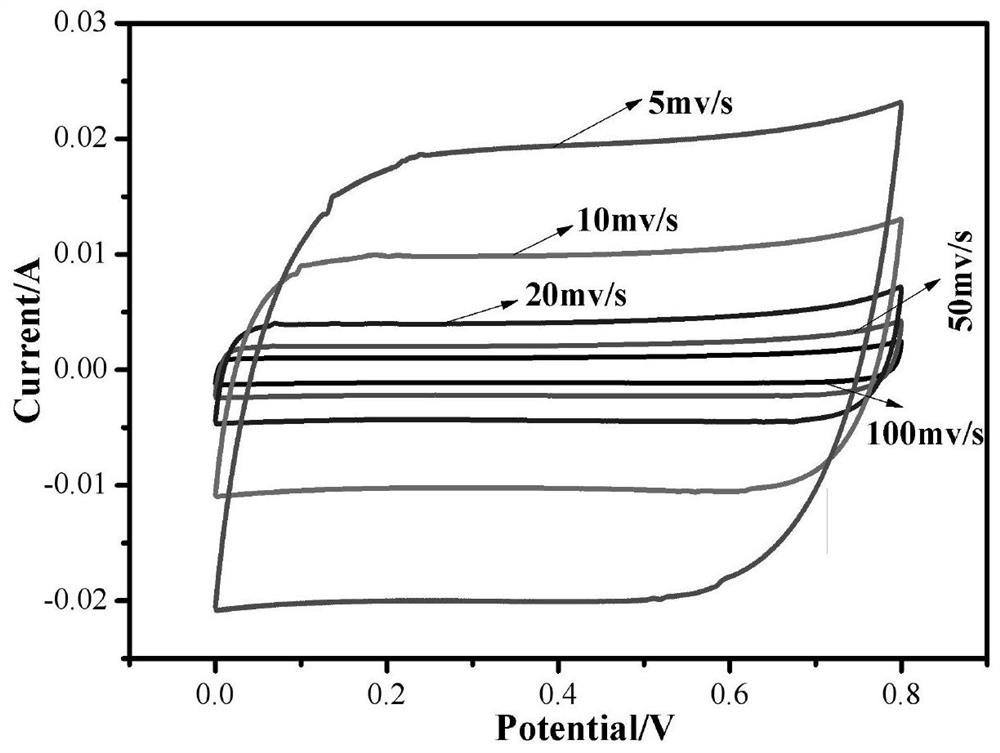

A composite electrode and porous carbon technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of non-environmentally friendly electrode material sources, expensive and unfavorable prices, and low specific capacitance, so as to improve electrochemical performance , good reversibility, high specific capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

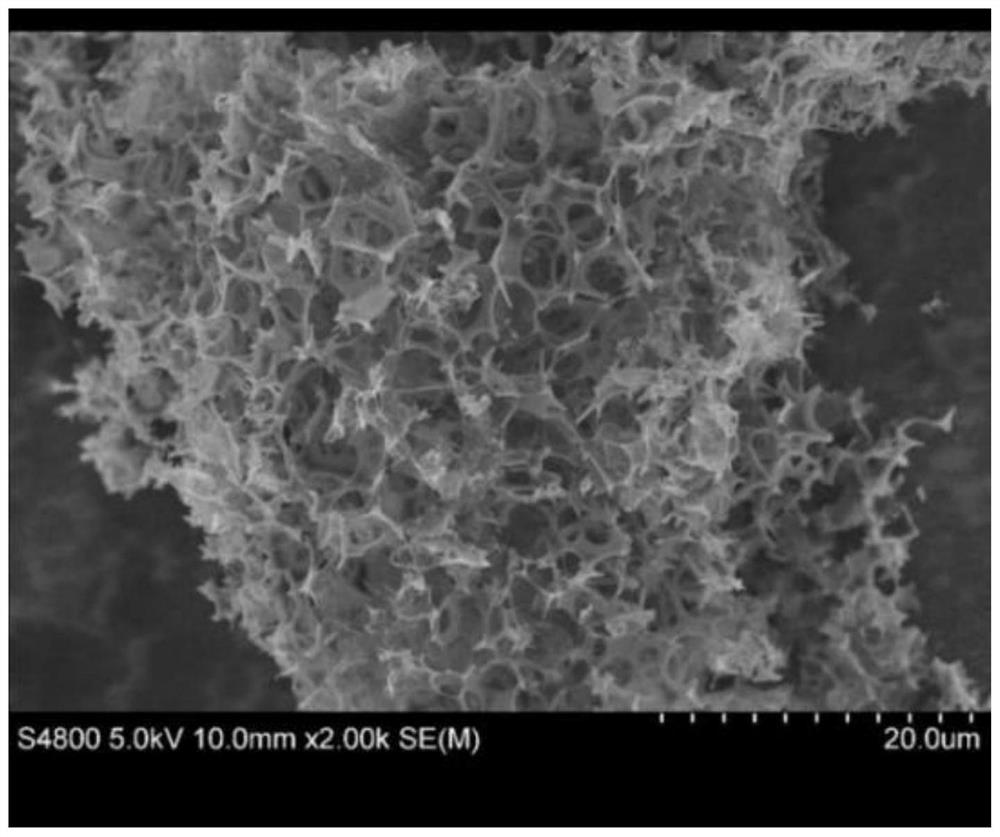

Embodiment 1

[0044] 1. Rinse the ginkgo leaves with distilled water, dry them in an oven at 90°C, and pulverize them to obtain ginkgo leaf powder with a particle size of 1.0mm;

[0045] 2. Weigh 5g of ginkgo powder and dissolve it in 55ml of deionized water, stir and add 10ml of acetic acid to form a viscous solution, put it in an autoclave, react at 200°C for 2h, the heating rate is 5°C / min, cool down naturally, and vacuum pump The brown-black substance was obtained by filtration, washed with deionized water until neutral, and dried overnight at 105°C;

[0046] 3. Mix the dried substance with urea and KOH at a mass ratio of 1:1:1.5, grind until uniform, move to a tube furnace, set the heating rate at 5°C / min, from room temperature to 800°C, heat treatment 2h, natural cooling, the whole process is protected by argon atmosphere, and a black product is obtained;

[0047] 4. Wash the black product with 1M HCl until no bubbles are generated, then wash with distilled water until neutral, and d...

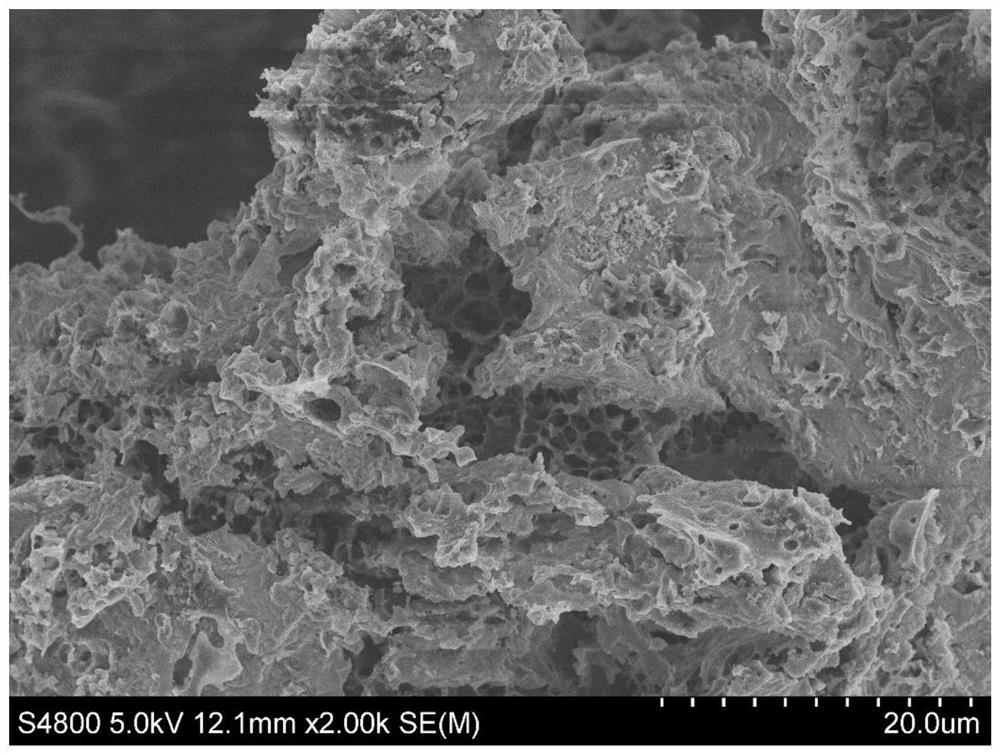

Embodiment 2

[0062] 1. Rinse the ginkgo leaves with distilled water, dry them in an oven at 80°C, and pulverize them to obtain ginkgo leaf powder with a particle size of 0.15 mm;

[0063] 2. Weigh 5g of ginkgo powder and dissolve it in 55ml of deionized water, stir and add 10ml of acetic acid to form a viscous solution, put it in an autoclave, react at 200°C for 2h, the heating rate is 5°C / min, cool down naturally, and vacuum pump The brown-black substance was obtained by filtration, washed with deionized water until neutral, and dried overnight at 105°C;

[0064] 3. Mix the dried substance with urea and KOH at a mass ratio of 1:1:1.5, grind until uniform, move to a tube furnace, set the heating rate at 5°C / min, from room temperature to 800°C, heat treatment 2h, natural cooling, the whole process is protected by argon atmosphere, and a black product is obtained;

[0065] 4. Wash the black product with 1M HCl until no bubbles are generated, then wash with distilled water until neutral, and...

Embodiment 3

[0072] 1. Rinse the ginkgo leaves with distilled water, dry them in an oven at 100°C, and pulverize them to obtain ginkgo leaf powder with a particle size of 0.15mm;

[0073] 2. Weigh 5g of ginkgo powder and dissolve it in 55ml of deionized water, stir and add 10ml of acetic acid to form a viscous solution, put it in an autoclave, react at 200°C for 2h, the heating rate is 5°C / min, cool down naturally, and vacuum pump The brown-black substance was obtained by filtration, washed with deionized water until neutral, and dried overnight at 105°C;

[0074]3. Mix the dried substance with urea and KOH at a mass ratio of 1:1:1.5, grind until uniform, move to a tube furnace, set the heating rate at 5°C / min, from room temperature to 800°C, heat treatment 2h, natural cooling, the whole process is protected by argon atmosphere, and a black product is obtained;

[0075] 4. Wash the black product with 1M HCl until no bubbles are generated, then wash with distilled water until neutral, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com