Doped and coated composite modified lithium cobalt oxide LCMO@BT and preparation method and application thereof

A kind of technology of lithium cobaltate and lithium cobaltate, applied in the direction of active material electrode, positive electrode, structural parts, etc., can solve the problems of unsatisfactory requirements, insignificant effect, and incapable of industrialization, and achieve low cost and simple and reliable synthesis process control, short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

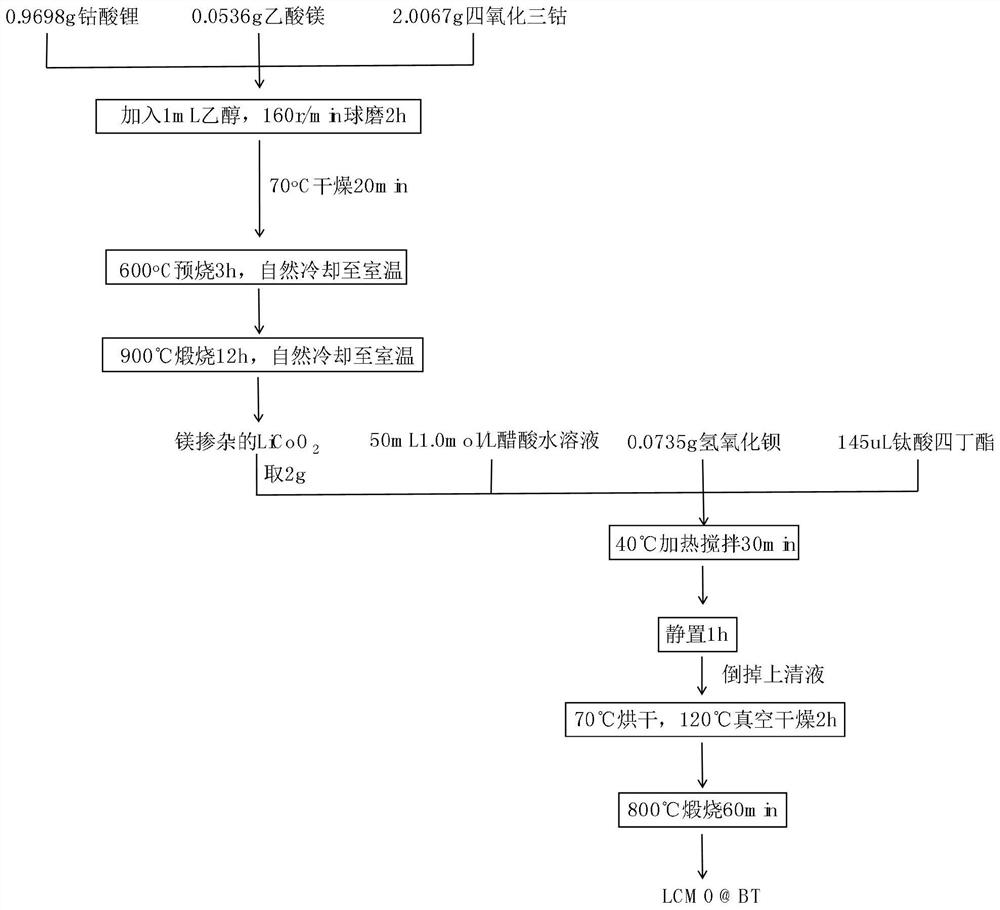

Embodiment 1

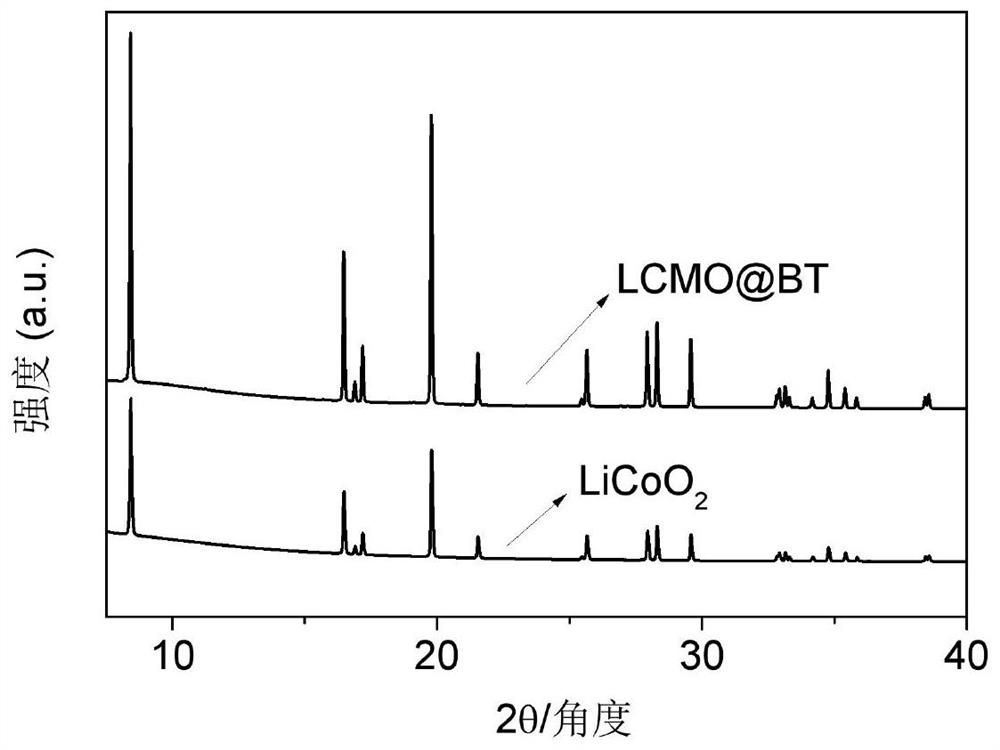

[0069] by LiCo 0.99 Mg 0.01 o 2 The chemical formula lithium carbonate 0.9698g (for preventing the volatilization of lithium source, prepares by the mol ratio of excessive 5%), magnesium acetate 0.0536g and tricobalt tetroxide 2.0067g are poured in the stainless steel ball mill jar. Add about 1.0 mL of absolute ethanol, and ball mill at a speed of 160 r / min for 2 h. Subsequently, the material was put into an oven at 70°C for 30 min to remove ethanol. After grinding, the mixture was pre-fired at 600°C for 3 hours in a muffle furnace, and cooled with the furnace. Grinding, calcining the calcined product at 900°C for 12h (5°C / min heating), cooling with the furnace to obtain lithium cobalt oxide doped with 1% magnesium.

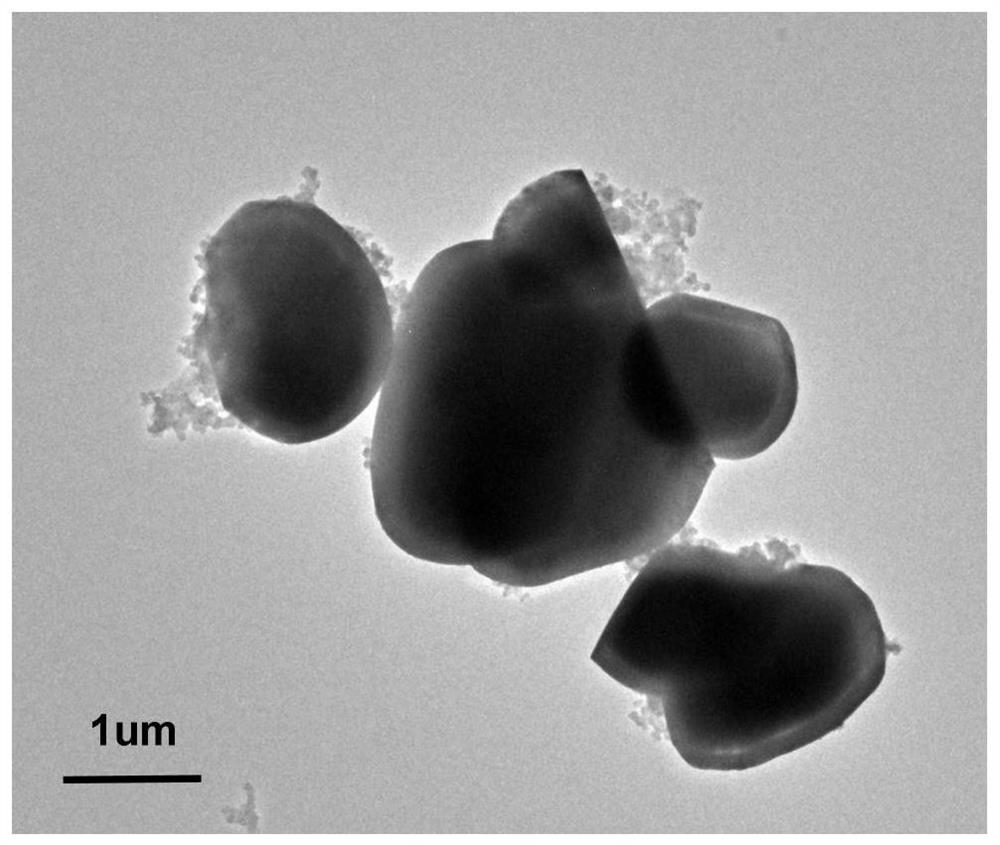

[0070] Prepare 0.0735 g of barium hydroxide and 145 uL of tetrabutyl titanate at a molar ratio of 1:1; weigh 2.0 g of lithium cobaltate doped with magnesium according to the mass ratio of the total mass of barium-titanium double metal oxide to lithium cobalta...

Embodiment 2

[0072] The experimental method of this embodiment is basically the same as that of Example 1. The magnesium source used in this embodiment is magnesium nitrate, the lithium source is lithium nitrate, and the doping molar weight of magnesium is 0.05%. The mass ratio of doped lithium cobaltate is 0.03.

Embodiment 3

[0074] The experimental method of this embodiment is basically the same as that of Example 1. The magnesium source used in this embodiment is magnesium oxide, the lithium source is lithium nitrate, and the doping molar weight of magnesium is 3%. The mass ratio of doped lithium cobaltate is 0.07.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com