Method for refining byproduct hydrogen halide gas in halogenated hydrocarbon production process

A technology of production process and refining method, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of short life of the adsorber, long desorption time, high energy consumption, etc., to avoid pollution and corrosion problems, desorption The effect of short time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: When benzene is chlorinated at high temperature in a factory to produce chlorinated benzene, the mixed gas produced by the reaction contains by-product HCl gas, benzene and organic by-reaction products, wherein the benzene content is 40 mg / L.

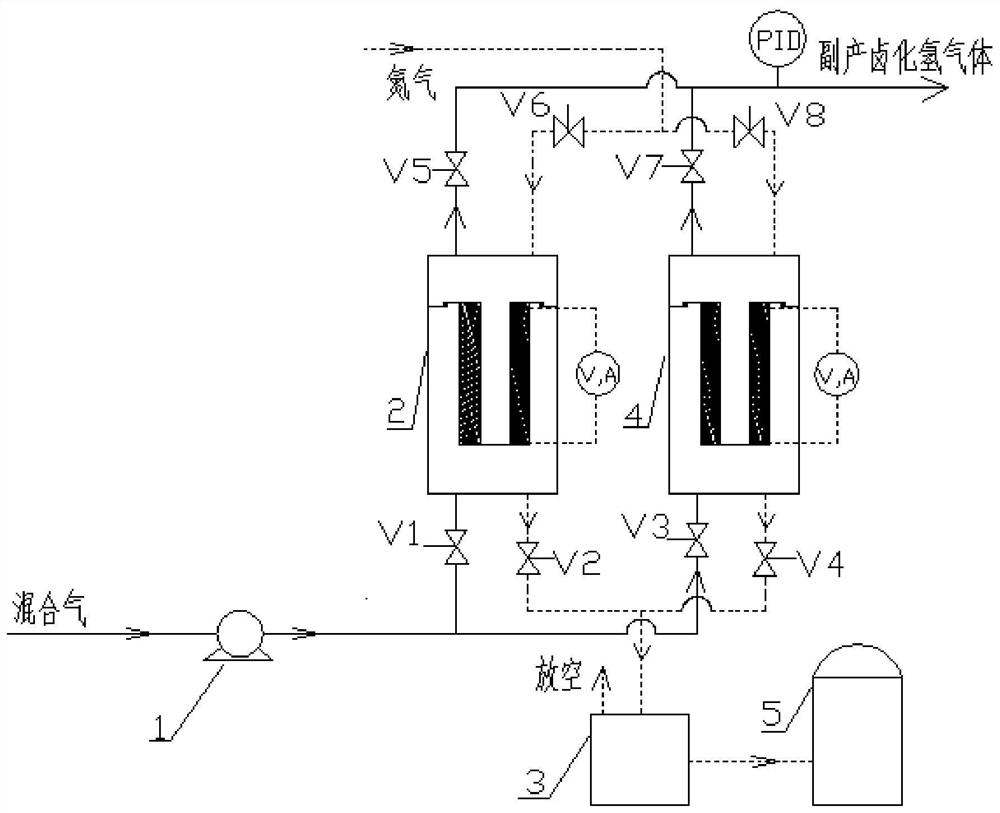

[0023] combine figure 1 As shown, the refining device for by-product hydrogen halide gas in the production process of halogenated hydrocarbons in this embodiment includes a fan 1, a first adsorber 2, a condensation system 3, a second adsorber 4, a solvent storage tank 5, and the first adsorber 2 and the second adsorber 4 are connected in parallel, the mixed gas inlet of the first adsorber 2 and the second adsorber 4 is connected with the mixed gas through the fan 1, and the adsorption outlet of the first adsorber 2 and the second adsorber 4 is connected with the The hydrogen halide gas collector is connected, and the adsorption columns in the first adsorber 2 and the second adsorber 4 are all adsorption columns of acti...

Embodiment 2

[0028] Embodiment 2: During the chlorination reaction process of toluene with chlorine as the chlorine source, the mixed gas produced contains by-product HCl gas, toluene and by-reaction products, wherein the content of toluene is 37 mg / L.

[0029] combine figure 1 As shown, the refining device of the by-product hydrogen halide gas in the halogenated hydrocarbon production process of this embodiment differs from the refining device in Example 1 in that the activated carbon fiber adsorption column in this embodiment is made of viscose-based fiber through A honeycomb activated carbon fiber adsorption column formed by carbonization, activation and processing.

[0030] The refining method of by-product hydrogen chloride gas in the toluene chlorination reaction process, it is finished by above-mentioned refining device, specifically comprises steps:

[0031] 1) Adsorption of organic impurities: collect the mixed gas of hydrogen chloride gas, toluene and organic side reaction produ...

Embodiment 3

[0034] Embodiment 3: In the production process of brominated paraffin and bromochlorinated paraffin, the mixed gas coming out from the reactor is mainly HBr and HCl gas, and a small amount of brominated paraffin and bromochlorinated paraffin.

[0035] combine figure 1 As shown, the refining device of the by-product hydrogen halide gas in the halogenated hydrocarbon production process of this embodiment differs from the refining device in Example 1 in that the activated carbon fiber adsorption column in this embodiment is made of acrylonitrile-based fiber through A paper-like activated carbon fiber adsorption column formed during carbonization, activation and processing.

[0036] The refining method of brominated paraffin and brominated chlorinated paraffin production process by-product HBr and HCl gas, it is realized by above-mentioned refining device, comprises steps:

[0037] 1) Adsorption of organic impurities: In the production process of brominated paraffin and bromochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com