Industrial preparation method of hexamethylenediamine

A hexamethylenediamine, industrial technology, applied in the field of industrial preparation of hexamethylenediamine, can solve the problems of synthetic route, complex synthesis technology, dependence on imports of adiponitrile, complex catalyst technology, etc., and achieves simple and fast reaction operation and route, and reaction The effect of low cost and good use prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

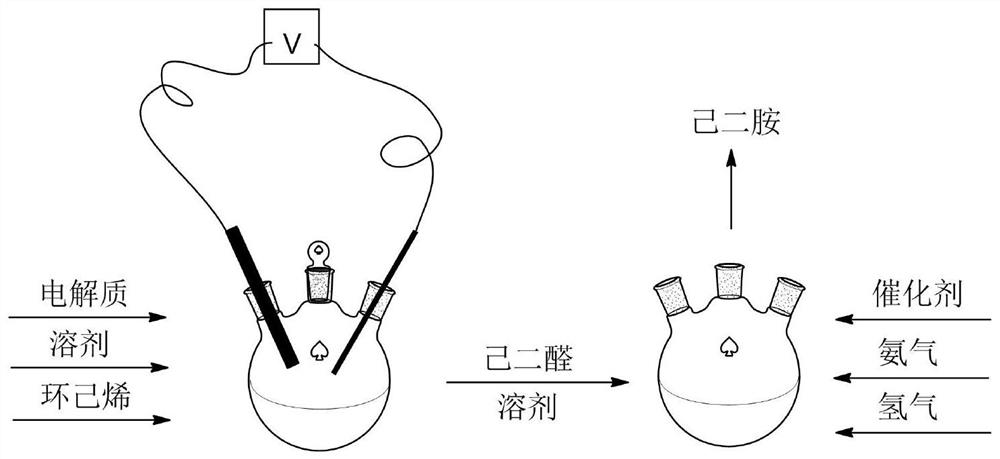

[0022] A kind of industrial preparation method of hexamethylenediamine of the present invention comprises the following steps:

[0023] 1) After dissolving cyclohexene in the first organic solvent, electrocatalytic oxidation reaction is carried out in the reaction kettle, and the reaction solution is obtained by constant potential electrolysis, and then adipaldehyde is obtained by vacuum distillation;

[0024] 2) dissolving the adipaldehyde obtained in step 1 in the second organic solvent, passing through ammonia and hydrogen, and performing reductive amination reaction under the action of a supported nickel catalyst to obtain hexamethylenediamine;

[0025] Concrete reaction general formula is as follows:

[0026] .

[0027] In the step 1, the electrode used in the electrocatalytic oxidation reaction is a platinum-graphite electrode or a Pb-Ti electrode or a Ni-Cu electrode, and the platinum-graphite electrode is to place the burnt platinum electrode in a sulfuric acid solu...

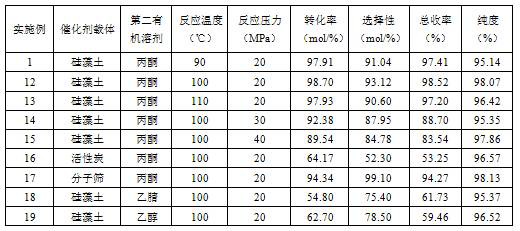

Embodiment 1

[0040] Using 0.5mol / L sulfuric acid as the supporting electrolyte, the platinum-graphite electrode constitutes the electrolysis system: the polished and cleaned graphite rod is used as the cathode, and the polished, burned and cleaned platinum sheet is used as the anode (with an area of 4 cm 2 ), placed in a dry electrolyzer without a diaphragm, and the electrolyte is a 0.5mol / L sulfuric acid solution. Under magnetic stirring, constant potential electrolysis was performed, and cyclic voltammetry scanning was performed until a reproducible and stable CV curve appeared, and the electrode potential was controlled at 1.5V.

[0041] Add 80ml of acetone to 10ml of cyclohexene and stir thoroughly to dissolve cyclohexene in acetone to obtain a cyclohexene solution, then add the cyclohexene solution to the reaction kettle, and pass through a 1.5V constant potential, -10°C, 5MPa state, the electrocatalytic oxidation reaction was carried out for 2 h. The obtained reaction liquid was d...

Embodiment 2

[0045] Using 0.1mol / L sulfuric acid as the supporting electrolyte, platinum-graphite electrodes constitute the electrolytic system: the polished and cleaned graphite rod is used as the cathode, and the polished, burned and cleaned platinum sheet is used as the anode (with an area of 4 cm 2 ), placed in a dry electrolytic cell without a diaphragm, and the electrolyte is a 0.1mol / L sulfuric acid solution. Under magnetic stirring, electrolyze at constant potential, and perform cyclic voltammetry scanning until a reproducible and stable CV curve appears, and the electrode potential is controlled at 1.3V.

[0046] Add 40ml of acetone to 10ml of cyclohexene and stir thoroughly to dissolve cyclohexene in acetone to obtain a cyclohexene solution, then add the cyclohexene solution to the reaction kettle, and pass through a 1.5V constant potential, 0°C, 8MPa state , the electrocatalytic oxidation reaction was carried out for 3 h. The obtained reaction liquid was distilled under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com