High-toughness resin coating internal crosslinking type dispersing agent and preparation method thereof

A technology of resins and dispersants, applied in the direction of coating, etc., can solve the problems of flexibility and easy winding, and achieve the effects of facilitating reaction, avoiding winding, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

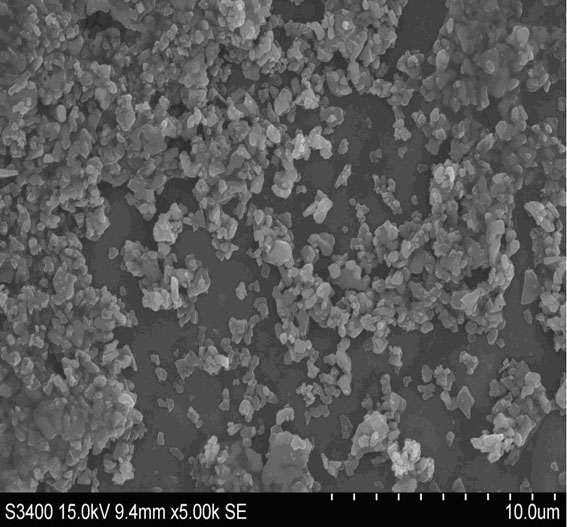

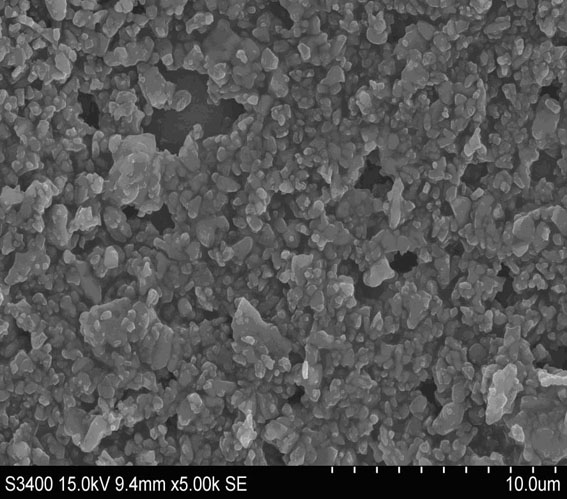

Image

Examples

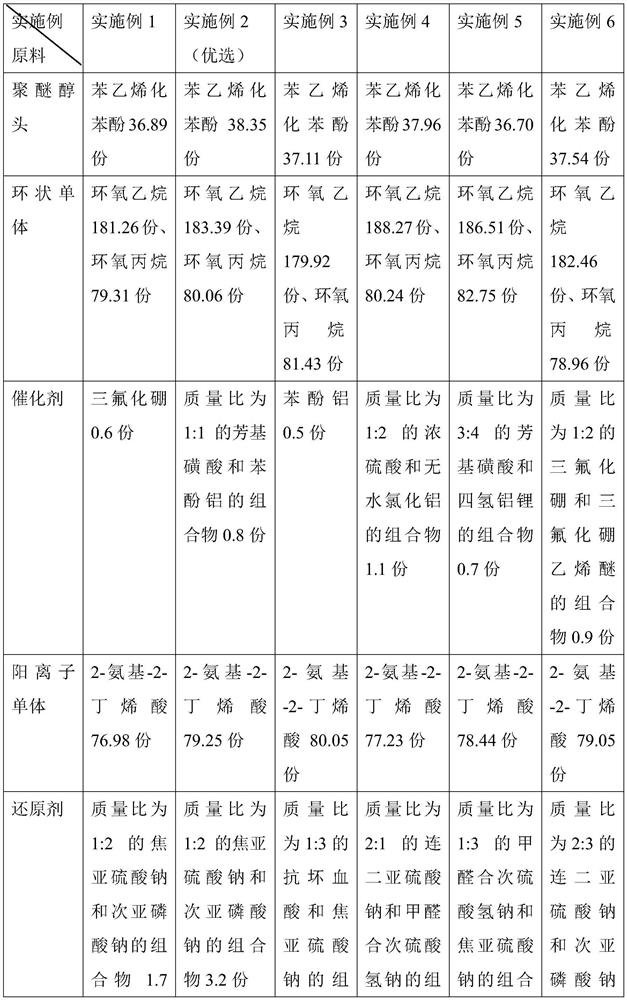

Embodiment 1

[0043] A high-tough resin coating inner crosslinking type dispersing agent and a preparation method thereof, polymerized by the following components, each component comprising:

[0046] 79.31 copies of propylene oxide;

[0047] 0.6 boron trifluoride;

[0048] 2-amino-2-butene acid 76.98 parts;

[0049]1.7 parts of the mass ratio of 1: 2 sulfate and sodium secondary phosphite;

[0050] The mass ratio of 1: 1 peroxide diisopropyl carbonate and 3.6 copies;

[0051] 1.1 parts of mercaptoacetic acid;

[0052] 4.2 parts of methanol sodium and ethanolamine of 3: 4;

[0053] The rest is water, with a total mass of 1000.

[0054] A high tough resin coating end-linked type dispersing agent and a preparation method thereof, characterized in that the preparation process includes the following operation steps:

[0055] Step 1: 36.89 parts of styrene phytinol and 0.6 parts of the boron trifle, and the nitrogen replacement was added t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com