Poly(p-phenylene benzobisoxazole) fiber spinning forming method

A technology of benzobisoxazole and polyparaphenylene, which is applied in the directions of dry spinning, wet spinning, and fiber processing, can solve the problems of limiting fiber properties, limiting mechanical properties, and high phosphoric acid residues, and improving the fiber forming effect. , to eliminate the jitter of silk strips and increase the effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

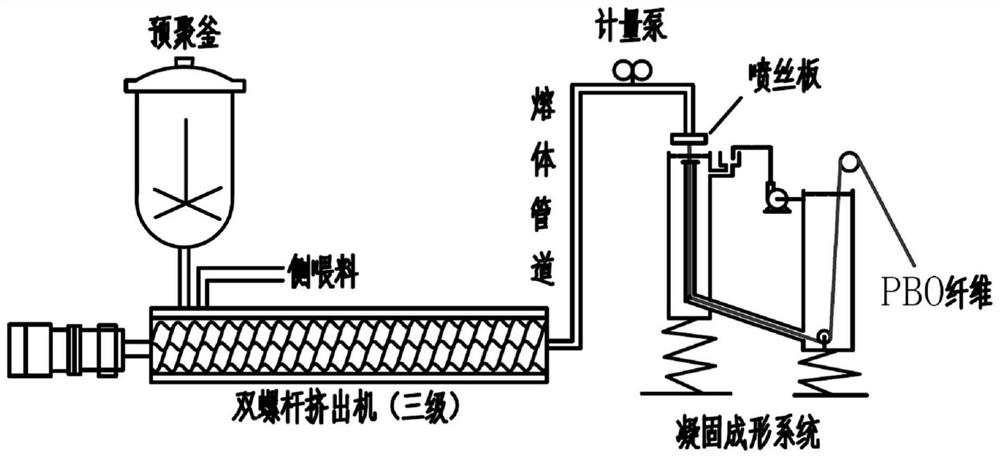

[0032] A kind of spinning device of PBO fiber, its specific structure is as follows:

[0033]It consists of a prepolymerization tank, a twin-screw extruder, a melt pipeline, a metering pump, a spinneret and a solidification forming system connected in sequence, wherein the prepolymerization tank is set at the feed end of the twin-screw extruder, and the twin-screw extruder The discharge end is connected with a melt pipeline and a metering pump, and a spinneret is installed at the end of the melt pipeline, and the solidification forming system is located below the spinneret;

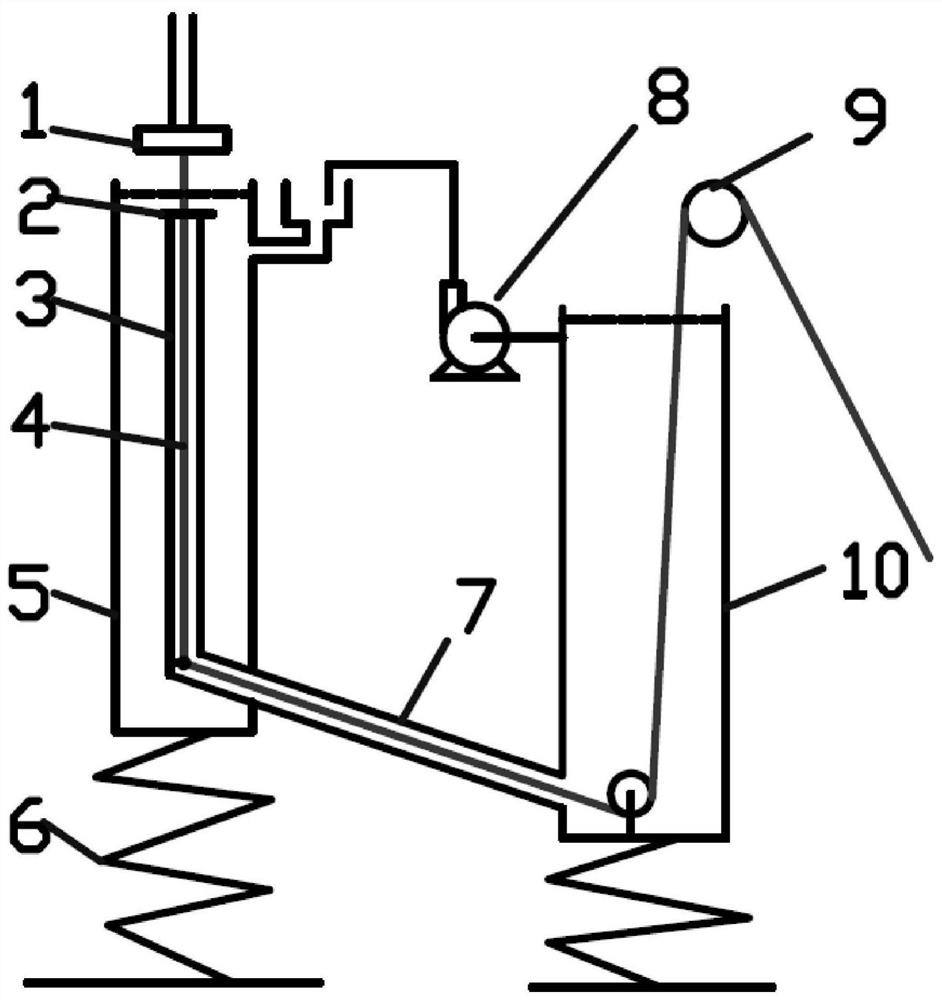

[0034] The specific structure of the solidification forming system is as follows:

[0035] It consists of two vertical coagulation baths: coagulation bath A and coagulation bath B in series, in which coagulation bath A is set under the spinneret, and a vertical spinning sleeve is arranged inside it, and a steady flow plate is installed at the entrance of the spinning sleeve , the bottom of the spinning s...

Embodiment 2

[0039] Utilize the spinning device of the PBO fiber described in embodiment 1, provide a kind of poly-p-phenylene benzobisoxazole fiber spinning forming method, comprise the steps:

[0040] (1) Add 500g of polyphosphoric acid solvent in a nitrogen-filled polymerization kettle, add 70.5g of polymerized monomer terephthaloyl chloride (TPC) and stir for 30min, add 1.2g of antioxidant stannous chloride, and heat up to 100°C , stirred for 30min, added 4,6-diaminoresorcinol hydrochloride (DAR·HCl) with a molar ratio of 0.85:1 to TPC, stirred for 10min, then added 162.2g of phosphorus pentoxide (P 2 o 5 ), stirred for 10 minutes, raised the temperature to 120°C, and stirred for 36 hours to complete the prepolymerization, and the intrinsic viscosity of the prepolymer was 0.4dl / g.

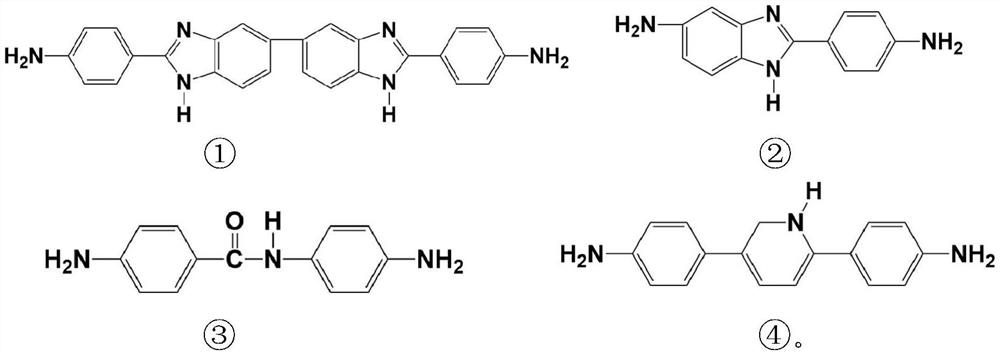

[0041] (2) The prepolymer is transported to the twin-screw extruder through pipelines, and at the same time, the third monomer ① with a molar ratio of DAR·HCl of 0.15:1 is added to the twin-screw extruder ...

Embodiment 3

[0046] Utilize the spinning device of the PBO fiber described in embodiment 1, provide a kind of poly-p-phenylene benzobisoxazole fiber spinning forming method, comprise the steps:

[0047] (1) Add 500g of polyphosphoric acid solvent in a nitrogen-filled polymerization kettle, add 97.6g of polymerized monomer terephthaloyl chloride (TPC) and stir for 60 minutes, add 1.8g of antioxidant stannous chloride, and heat up to 120°C , stirred for 60min, added 4,6-diaminoresorcinol hydrochloride (DAR·HCl) with a molar ratio of 0.95:1 to TPC, stirred for 20min, then added 189.3g of phosphorus pentoxide (P 2 o 5 ), stirred for 20 minutes, raised the temperature to 150°C, and stirred for 48 hours to complete the prepolymerization, and the intrinsic viscosity of the prepolymer was 1dl / g.

[0048] (2) The prepolymer is transported to the twin-screw extruder through pipelines, and at the same time, the third monomer ③ with a molar ratio of 0.05:1 to TPC is added to the twin-screw extruder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com