Iron-carbon composite material as well as preparation method and application thereof

A composite material, iron-carbon technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of weak binding force between iron nanoparticles and carbon particles, long preparation process time, and loading capacity Low-level problems, to achieve strong redox activity, increase effective utilization, and increase the effect of loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

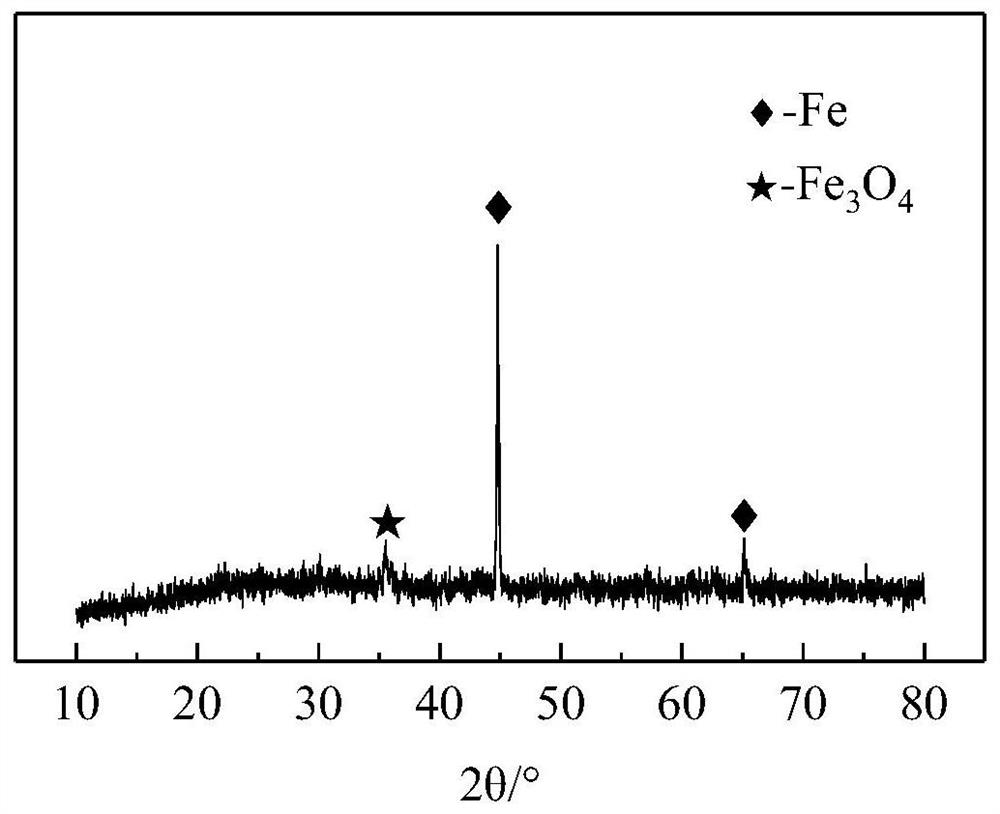

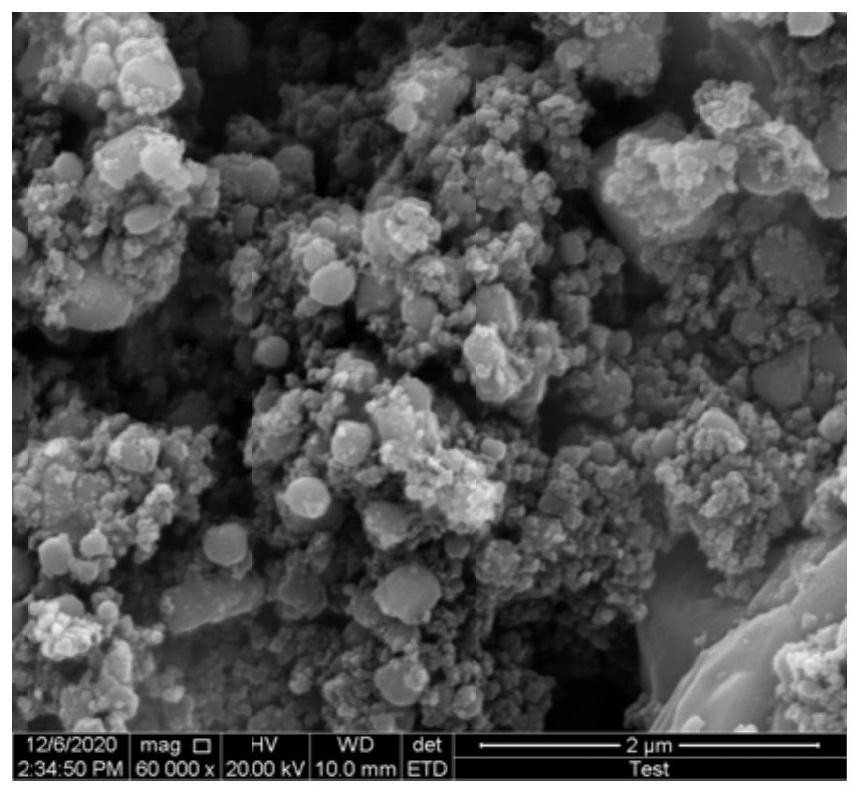

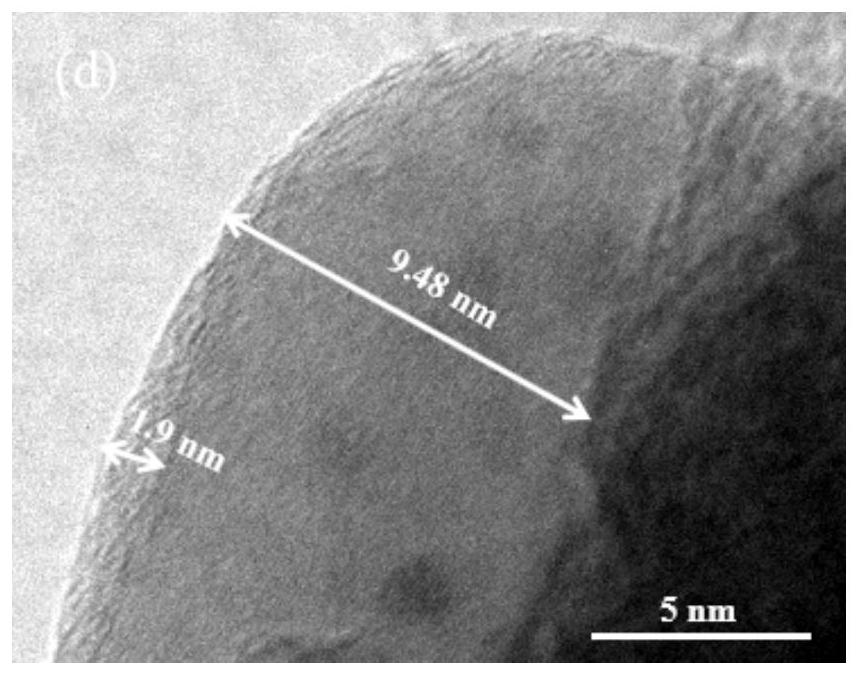

[0049] A kind of iron-carbon composite material of the present embodiment, its preparation method is as follows:

[0050] (1) Coal powder and ferrous sulfate are used as reaction raw materials, and methyl cellulose is used as a binder. According to the iron-carbon molar ratio of 1:1.2, the amount of binder is 1%, the ingredients are mixed uniformly, the particle size of the powder is controlled by granulation to be about 1 μm, and then put into the blast drying oven for 4 hours at 60°C, ground and sieved After separation, the precursor for preparing iron-carbon composite materials was obtained.

[0051] (2) Take 5g of the precursor obtained in step 1 and put it into the heating furnace, control the nitrogen flow rate to 100ml / min, the thickness of the precursor powder to be 1mm, and the partial pressure of the inert gas in the entire reaction system to be 90-95%, and heat it at 600°C Keep warm for 240min, then cool down to room temperature. Specifically, when the temperature...

Embodiment 2

[0056] A kind of iron-carbon composite material of the present embodiment, its preparation method is as follows:

[0057] (1) Taking graphite powder and ferric nitrate as reaction raw materials, taking stearic acid as binding agent. According to the iron-carbon molar ratio of 1:11, the amount of binder is 10%, the ingredients are mixed evenly, the particle size of the powder is controlled by granulation to be about 30 μm, and then put into a blast drying oven for 2 hours at 80°C, ground and sieved After separation, the precursor for preparing iron-carbon composite materials was obtained.

[0058] (2) Take 100g of the precursor obtained in step 1 and put it into the heating furnace, control the nitrogen flow rate to 5000ml / min, the powder thickness of the precursor is 30mm, and the partial pressure of the inert gas in the whole reaction system is 91-96%, and heat it at 1000°C Keep warm for 120min, then cool down to room temperature. Specifically, when the temperature is raise...

Embodiment 3

[0063] A kind of iron-carbon composite material of the present embodiment, its preparation method is as follows:

[0064] (1) With active carbon and ferrous carbonate as reaction raw materials, with polyvinyl alcohol as binding agent. According to the iron-carbon molar ratio of 1:5, the amount of binder is 5%, the ingredients are mixed uniformly, the particle size of the powder is controlled by granulation to be about 10 μm, and then put into a blast drying oven for 3 hours at 70°C, ground and sieved After separation, the precursor for preparing iron-carbon composite materials was obtained.

[0065] (2) Take 30g of the precursor obtained in step 1 and put it into the heating furnace, control the nitrogen flow rate to 1000ml / min, the powder thickness of the precursor is 10mm, and the partial pressure of the inert gas in the whole reaction system is 90-96%. Keep warm for 180min, then cool down to room temperature. Specifically, when the temperature is raised, when the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap