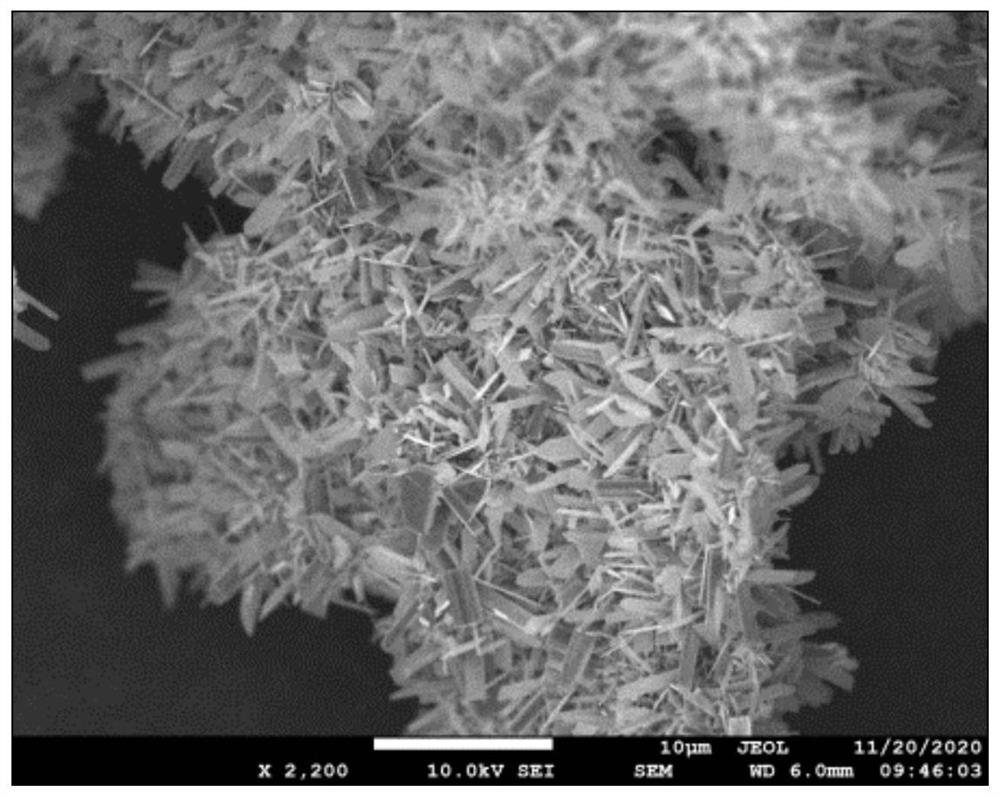

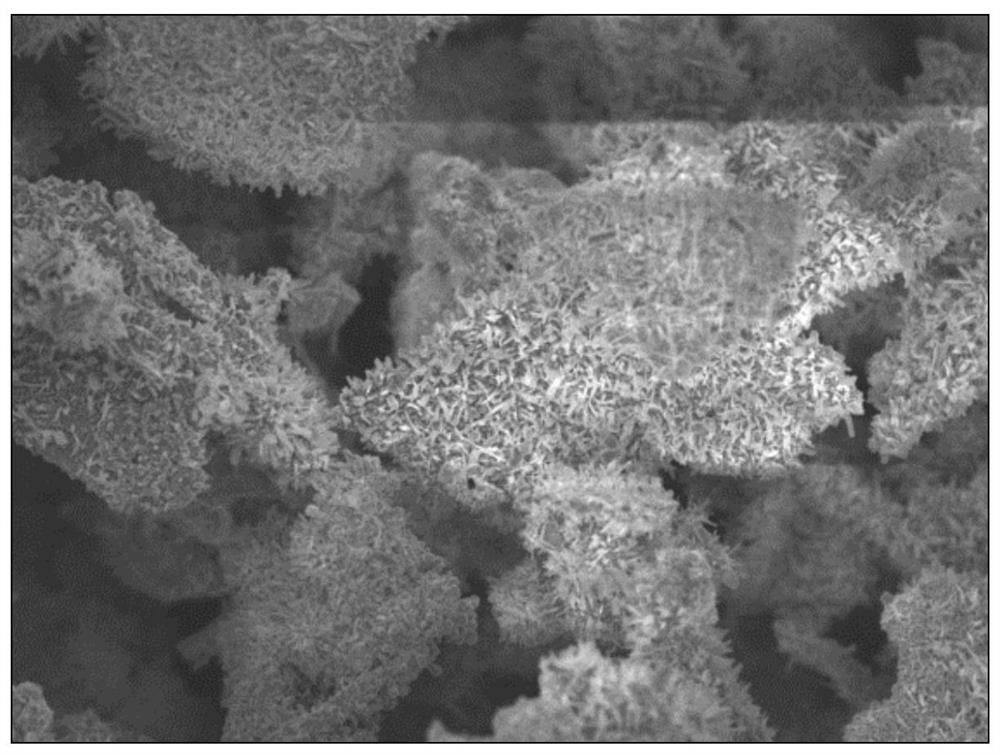

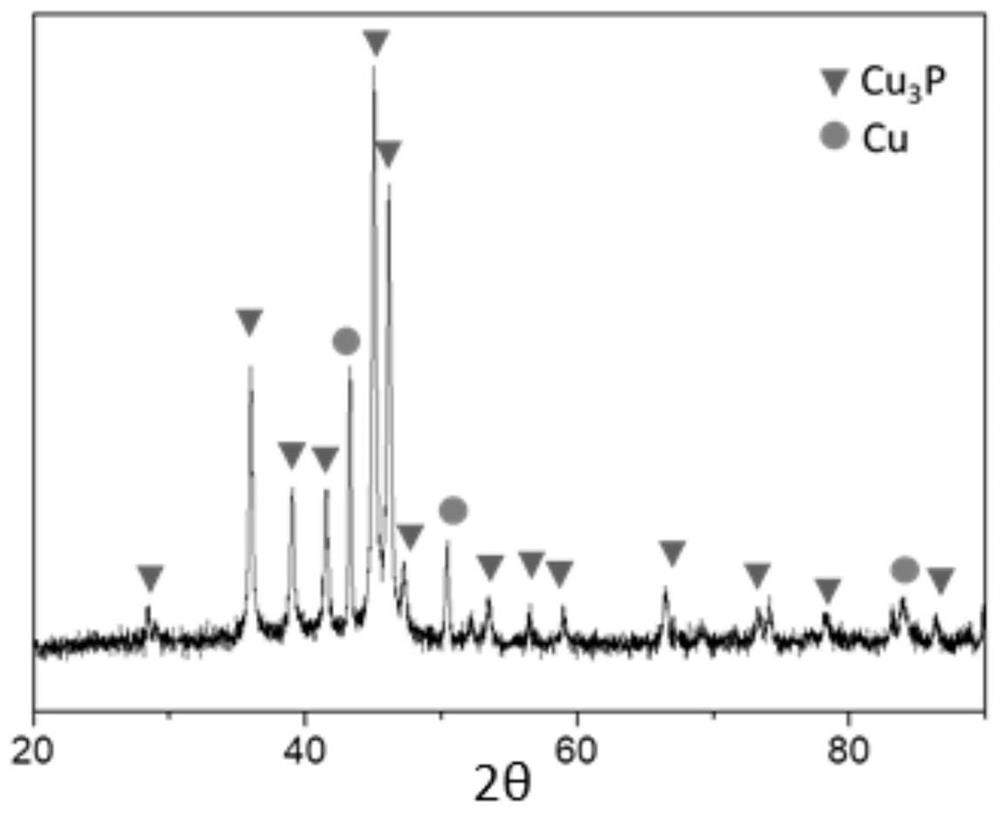

Preparation method of Cu-Cu3P material with nano array structure

A nano-array, cu-cu3p technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of high repeatability, quality improvement, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] Step 1. Mix 15 mL of deionized water, 0.3 g of glucose, and 0.12 g of polyvinylpyrrolidone and stir for 3 hours to obtain a clear mixed solution;

[0036] Step 2. Under stirring conditions, add copper sulfate solution dropwise to the clarified mixed solution obtained in step 1, and continue to stir at room temperature for 60 minutes, then transfer to a hydrothermal reaction kettle and react at 160° C. for 4 hours; The copper sulfate solution contains 0.8mmoL copper sulfate;

[0037] Step 3, centrifuging the product obtained by the reaction in step 3, washing it three times with deionized water and absolute ethanol successively, and obtaining copper nanosheets after vacuum drying;

[0038] Step 4, add 10g of water, 1.6g of sodium hydroxide and 3g of hydrogen peroxide solution with a mass fraction of 30% to the copper nanosheets obtained in 0.02g of step 3, and place in a hydrothermal reaction kettle and stir for 1mi...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] Step 1. Mix 20 mL of deionized water, 0.8 g of glucose, and 0.6 g of polyvinylpyrrolidone and stir for 4 hours to obtain a clear mixed solution;

[0047] Step 2. Under stirring conditions, add copper sulfate solution dropwise to the clarified mixed solution obtained in step 1, and continue to stir at room temperature for 30 minutes, then transfer to a hydrothermal reaction kettle and react at 200 ° C for 3 hours; The copper sulfate solution contains 1.0mmoL copper sulfate;

[0048] Step 3, centrifuging the product obtained by the reaction in step 3, washing it three times with deionized water and absolute ethanol successively, and obtaining copper nanosheets after vacuum drying;

[0049] Step 4: Add 6 g of water, 0.2 g of sodium hydroxide and 3 g of hydrogen peroxide solution with a mass fraction of 30% to 0.008 g of the copper nanosheets obtained in Step 3, and place in a hydrothermal reaction kettle and stir for ...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Mix 45mL deionized water, 1.5g glucose, and 1.8g polyvinylpyrrolidone and stir for 6 hours to obtain a clear mixed solution;

[0056] Step 2. Under stirring conditions, add copper sulfate solution dropwise to the clarified mixed solution obtained in step 1, and continue to stir at room temperature for 60 minutes, then transfer to a hydrothermal reaction kettle and react for 2.5 hours at 180° C.; Contain 1.8mmoL copper sulfate in the copper sulfate solution;

[0057] Step 3, centrifuging the product obtained by the reaction in step 3, washing it three times with deionized water and absolute ethanol successively, and obtaining copper nanosheets after vacuum drying;

[0058] Step 4, adding 10 g of water, 0.3 g of sodium hydroxide and 6.18 g of hydrogen peroxide solution with a mass fraction of 30% to the copper nanosheets obtained in 0.05 g of step 3, and placing it in a hydrothermal reaction kettle and stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com