Renewable ultrathin multilayer composite forward osmosis membrane as well as preparation method and application thereof

A multi-layer composite, forward osmosis membrane technology, applied in the field of membrane separation, can solve the problems of prolonging the membrane production process, increasing the cost, poor affinity of amine monomer aqueous solution, etc., to shorten the membrane production process, increase the cost, and improve the water The effect of flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

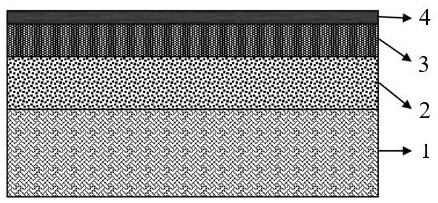

[0026] As another aspect of the technical solution of the present invention, it also relates to a preparation method of a renewable ultra-thin multi-layer composite forward osmosis membrane, which includes:

[0027] (1) Make the PE microporous membrane fully contact with the oil phase solution containing the acid chloride monomer first, and then fully contact with the water phase solution containing the amine monomer after drying, and make the acid chloride monomer and the amine monomer in the The surface of the PE microporous membrane is subjected to interfacial polymerization and heat treatment to generate a micro-crosslinked polyamide layer to obtain a micro-crosslinked polyamide layer / PE microporous membrane;

[0028] (2) Make the micro-crosslinked polyamide layer / PE microporous membrane obtained in step (1) fully contact with the mixed solution containing polyphenolic compounds and cage polysilsesquioxane (POSS for short), and react to form crosslinking Hydrogel superhydr...

Embodiment 1

[0068] (1) Immerse the PE microporous membrane in n-hexane solution with a concentration of 0.1g / L trimesoyl chloride, take it out after soaking for 0.5min, brush off the surface liquid, and immerse it in an aqueous solution with a concentration of 0.1g / L m-phenylenediamine , take it out after reacting for 0.5min, and heat treatment at 30°C for 1min to form a slightly cross-linked polyamide layer;

[0069] (2) Submerge the membrane prepared in step (1) in a mixed aqueous solution composed of 0.2g / L catechol and 0.2g / L POSS, take it out after 0.5h, and wash to obtain a superhydrophilic hybrid layer;

[0070] (3) Immerse the membrane prepared in step (2) in an aqueous solution of 0.01g / L ferric chloride, take it out after 0.5h, wash it, heat it in a microwave at 300°C for 10s, take it out, wash it, and obtain an adsorption catalytic functional layer, Obtain a renewable ultra-thin multi-layer composite forward osmosis membrane.

[0071] After testing, when the forward osmosis me...

Embodiment 2

[0073] (1) Immerse the PE microporous membrane in an acetone solution with a concentration of 50g / L terephthaloyl dichloride, take it out after soaking for 30 minutes, brush off the surface liquid, and immerse it in an aqueous solution with a concentration of 100g / L o-phenylenediamine, and react for 30 minutes After taking it out, heat treatment at 90°C for 30 minutes to form a slightly cross-linked polyamide layer;

[0074] (2) Submerge the membrane prepared in step (1) in a mixed aqueous solution composed of 10g / L dopamine and 10g / L POSS, take it out after 48h, and wash to obtain a superhydrophilic hybrid layer;

[0075] (3) Immerse the membrane prepared in step (2) in an aqueous solution of 10g / L cobalt chloride, take it out after 48 hours, wash it, heat it in microwave at 100°C for 600s, take it out, wash it, and obtain an adsorption catalytic functional layer, and obtain a renewable Ultra-thin multi-layer composite forward osmosis membrane.

[0076] After testing, when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com