A kind of organic solvent nanofiltration composite membrane whose active layer is molybdenum disulfide and preparation method thereof

A molybdenum disulfide and organic solvent technology, applied in the field of organic solvent nanofiltration composite membrane and its preparation, can solve the problems of low membrane selectivity, large molecular diffusion resistance, low flux, etc., and achieve improved nanofiltration performance and stability. Good, high solute rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Treatment of the basement membrane: prepare 2 g / L dopamine hydrochloride aqueous solution, and add an appropriate amount of tris to adjust the pH to 7-8, fully soak the organic microfiltration membrane, and place it on a shaking table at 25°C Shake in medium for 4 hours, after the shaking is over, pour off the dopamine hydrochloride aqueous solution, and put the modified organic microfiltration membrane in deionized water for later use.

[0037] Treatment of polydopamine layer: Under alkaline conditions and the presence of oxygen, dopamine hydrochloride will undergo surface self-polymerization surface modification on the basement membrane to form a super-adhesive polydopamine layer, the same below.

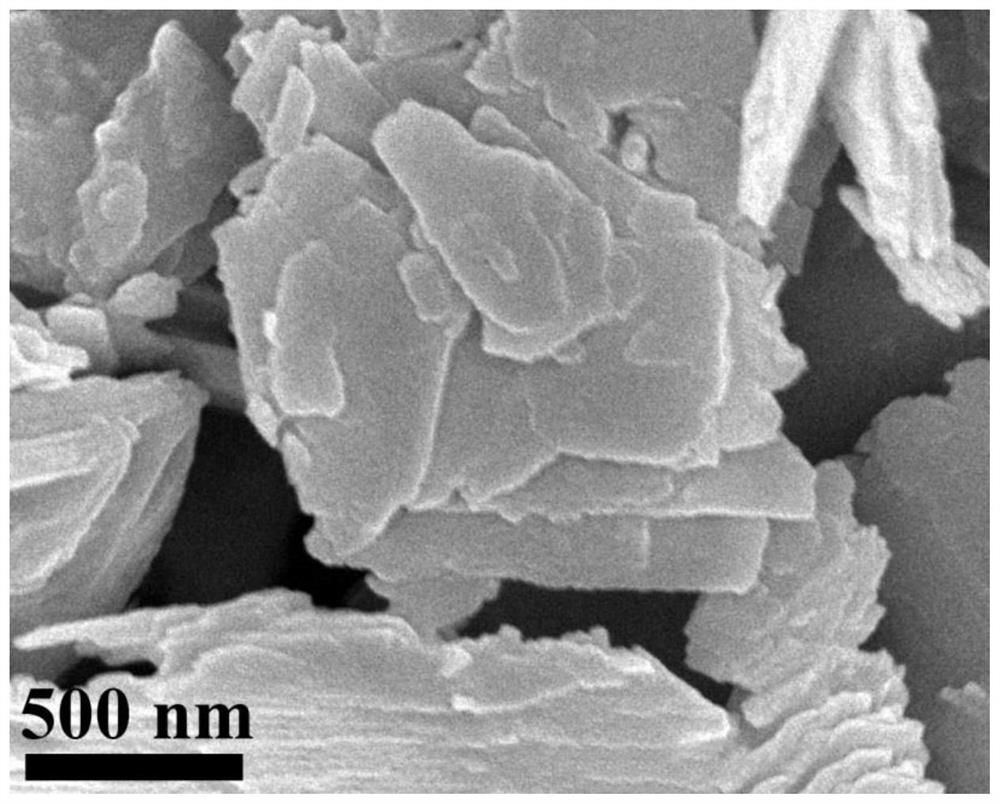

[0038] Preparation of molybdenum disulfide nanosheet dispersion: disperse 0.3 g molybdenum disulfide powder in 1 L of mixed solvent of absolute ethanol and water (absolute ethanol: water mass ratio is 7:3); the thickness of molybdenum disulfide nanosheets About 1nm, side wi...

Embodiment 2

[0047] The treatment of the base film, the treatment of the polydopamine layer and the preparation process of the molybdenum disulfide nanosheet dispersion are the same as in Example 1.

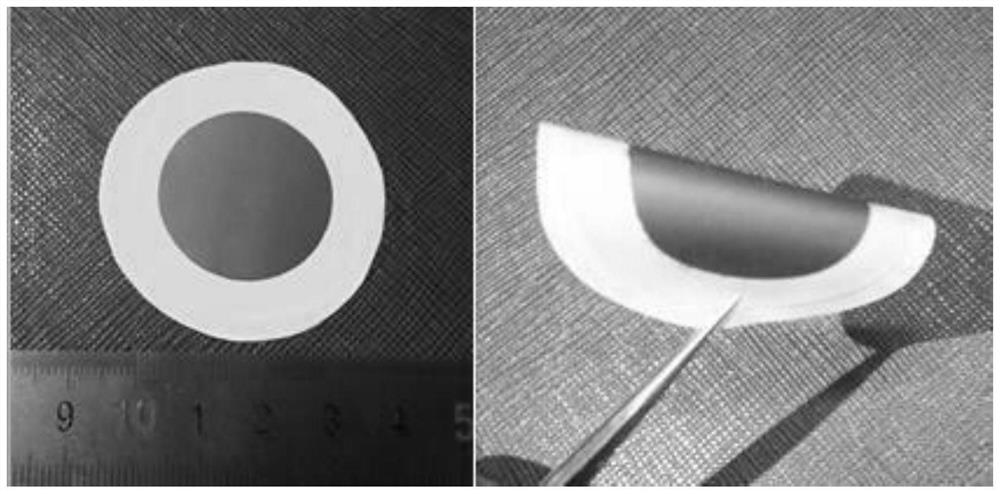

[0048] 600 mL of the prepared molybdenum disulfide nanosheet dispersion was self-stacked on the base film by low-speed suction filtration, and the thickness of the active layer obtained was 2 μm.

[0049] Its organic solvent flux, dye retention performance and long-term operation stability were tested, and its performance is as follows:

[0050] Solvent flux performance of composite membranes:

[0051] Acetonitrile throughput of 5795 L / m 2 h bar, the flux to acetone is 5681.2 L / m 2 h bar, the flux to ethyl acetate is 4412.6 L / m 2 h bar, the methanol flux is 3639.4 L / m 2 h bar, the flux of p-toluene is 1837.3L / m 2 h bar, the flux to water is 1773.1 L / m 2 h bar with a flux of 858.7 L / m for isopropanol 2 h bar, flux to n-hexane 135.2 L / m 2 h bar.

[0052] The rejection performan...

Embodiment 3

[0055] The treatment of the base film, the treatment of the polydopamine layer and the preparation process of the molybdenum disulfide nanosheet dispersion are the same as in Example 1.

[0056] 900 mL of the prepared molybdenum disulfide nanosheet dispersion was self-stacked on the base film by low-speed suction filtration, and the thickness of the active layer obtained was 3 μm.

[0057] Its organic solvent flux, dye retention performance and long-term operation stability were tested, and its performance is as follows:

[0058] Solvent flux performance of composite membranes:

[0059] Acetonitrile flux of 4254.7 L / m 2 h bar, the flux to acetone is 4235.6 L / m 2 h bar, the flux to ethyl acetate is 3079.9 L / m 2 h bar, the methanol flux is 2896.1 L / m 2 h bar, the flux of p-toluene is 1339.9 L / m 2 h bar, the flux to water is 1350.8 L / m 2 h bar with a flux of 664.3 L / m to isopropanol 2 hbar, flux to n-hexane 94.3 L / m 2 h bar.

[0060] The rejection performance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com