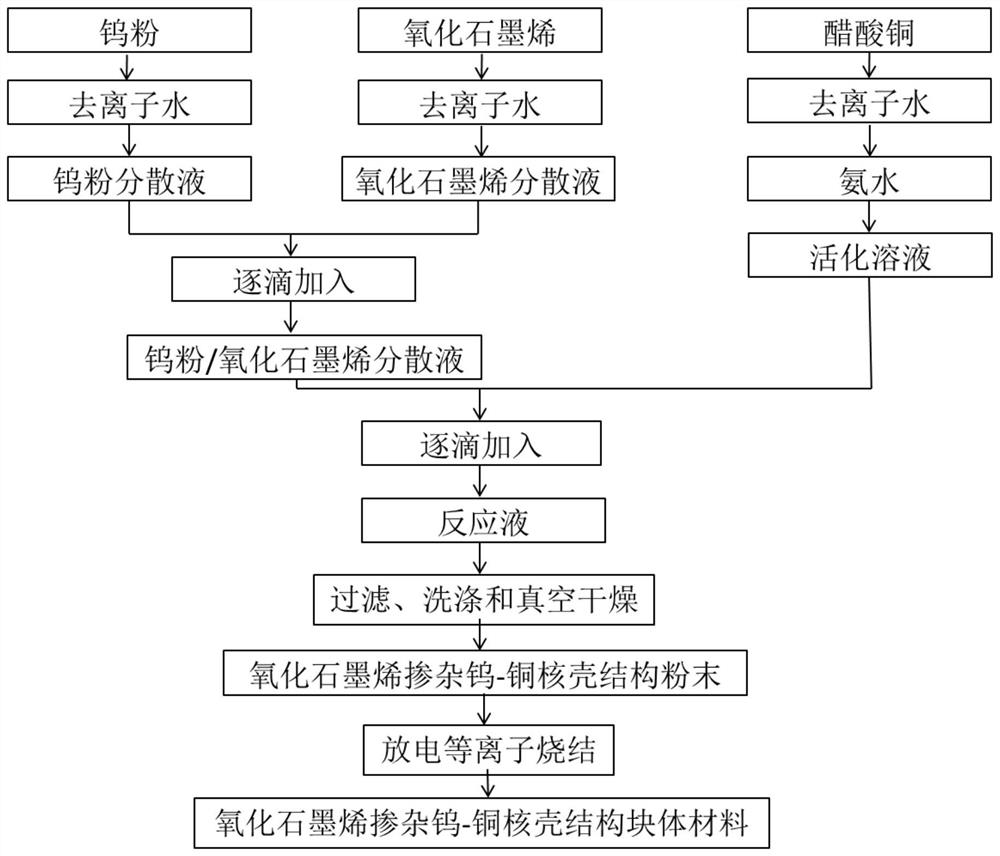

Preparation method of graphene oxide doped tungsten-copper core-shell structure material

A core-shell structure, graphene technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problem of difficult to obtain microstructure and properties, complex preparation process by co-reduction method, poor wettability of tungsten-copper interface, etc. problems, to achieve the effect of reducing temperature, improving interface wettability, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

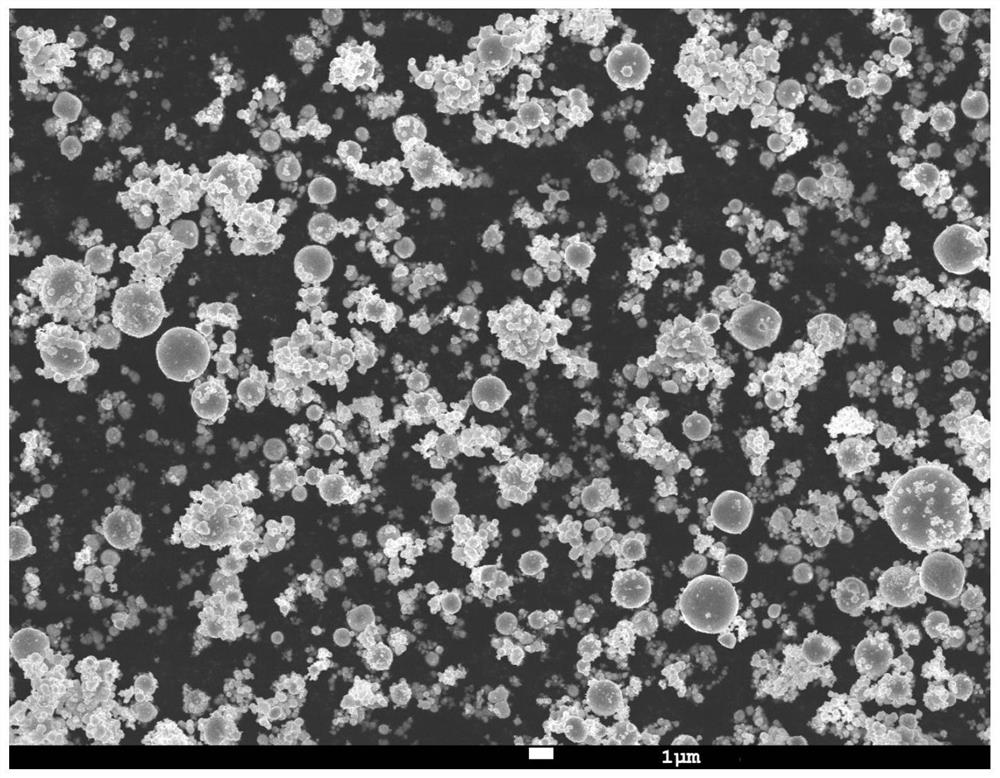

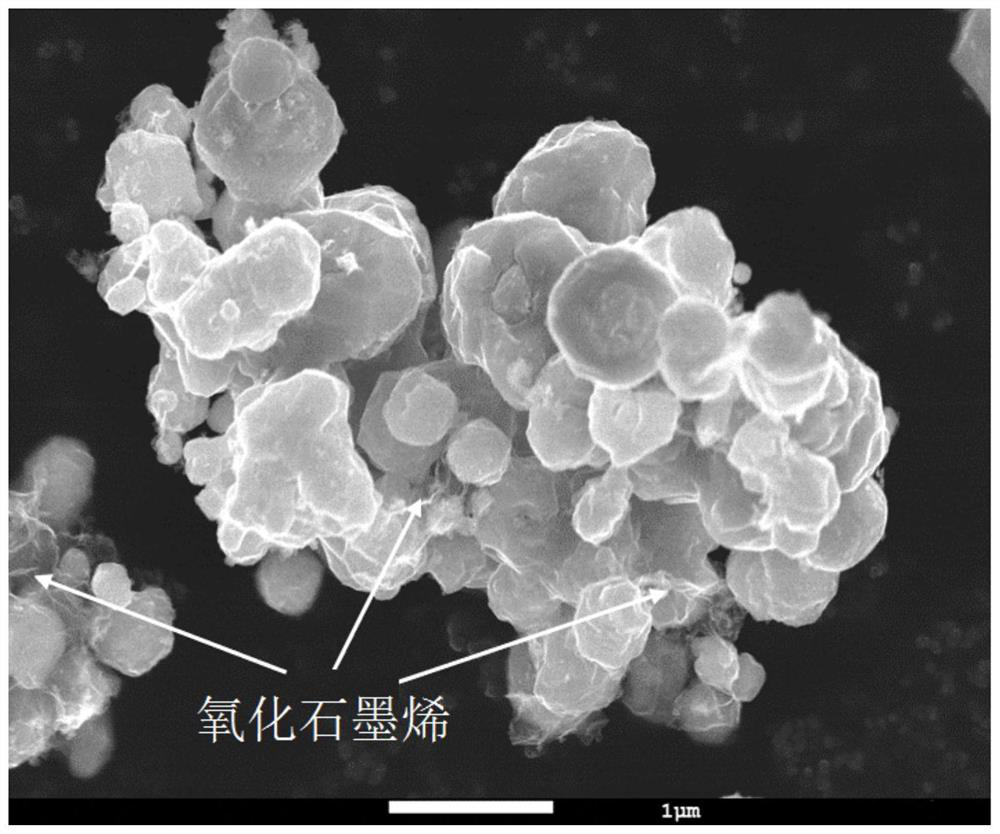

Examples

Embodiment 1

[0037] This embodiment includes the following steps:

[0038] Step 1. Add 50g of tungsten powder and 0.2g of graphene oxide into 200mL of deionized water respectively, and then perform stirring and ultrasonic treatment in turn to obtain tungsten powder dispersion and graphene oxide dispersion; the particle size of the tungsten powder is 20nm~ 5μm;

[0039] Step 2, stirring the tungsten powder dispersion obtained in step 1, then adding dropwise the graphene oxide dispersion obtained in step 1 to obtain a tungsten powder / graphene oxide dispersion;

[0040] Step 3: Add 62g of copper acetate to 200mL of deionized water, then add 100mL of ammonia water, and then perform ultrasound to obtain an activation solution;

[0041] Step 4. Add the tungsten powder / graphene oxide dispersion liquid obtained in step 2 to the activation solution obtained in step 3 dropwise under the conditions of water bath and stirring to obtain a reaction solution; the temperature of the water bath is 45 ℃, ...

Embodiment 2

[0063] This embodiment includes the following steps:

[0064] Step 1. Add 50g of tungsten powder and 0.5g of graphene oxide into 200mL of deionized water respectively, and then perform stirring and ultrasonic treatment in turn to obtain a tungsten powder dispersion and a graphene oxide dispersion; the particle size of the tungsten powder is 1 μm~ 5μm;

[0065] Step 2, stirring the tungsten powder dispersion obtained in step 1, then adding dropwise the graphene oxide dispersion obtained in step 1 to obtain a tungsten powder / graphene oxide dispersion;

[0066] Step 3: Add 78g of copper acetate to 200mL of deionized water, then add 100mL of ammonia water, and then perform ultrasound to obtain an activation solution;

[0067] Step 4: Add the tungsten powder / graphene oxide dispersion obtained in step 2 to the activated solution obtained in step 3 dropwise under the conditions of water bath and stirring to obtain a reaction solution; the temperature of the water bath is 80 ℃, the ...

Embodiment 3

[0072] This embodiment includes the following steps:

[0073]Step 1. Add 50g of tungsten powder and 0.05g of graphene oxide into 200mL of deionized water respectively, and then perform stirring and ultrasonic treatment in turn to obtain tungsten powder dispersion and graphene oxide dispersion; the particle size of the tungsten powder is 20nm~ 1μm;

[0074] Step 2, stirring the tungsten powder dispersion obtained in step 1, then adding dropwise the graphene oxide dispersion obtained in step 1 to obtain a tungsten powder / graphene oxide dispersion;

[0075] Step 3: Add 47g of copper acetate to 200mL of deionized water, then add 100mL of ammonia water, and then perform ultrasound to obtain an activation solution;

[0076] Step 4, the tungsten powder / graphene oxide dispersion liquid obtained in step 2 is under the condition of water bath and stirring, the activation solution obtained in step 3 is added dropwise to react, and the reaction solution is obtained; the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com