Ammonia nitrogen remover for chicken farm manure treatment

A feces treatment and remover technology, applied in sludge treatment, special treatment targets, biological sludge treatment, etc., can solve problems such as increased cost of raising chickens, hidden dangers to health, impact on poultry growth, etc., to achieve inhibition of generation and volatilization, inhibition of The effect of ammonia volatilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

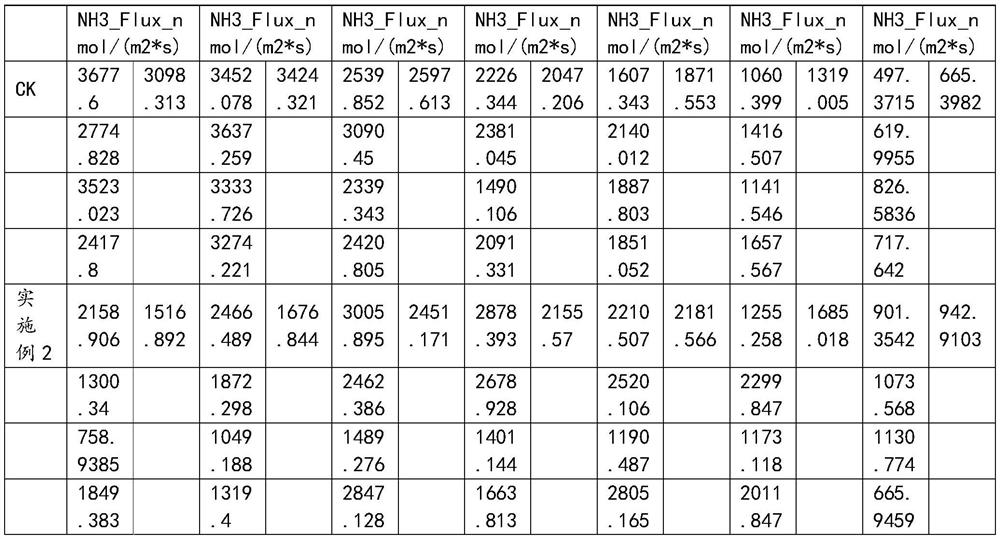

Image

Examples

Embodiment 1

[0020] An ammonia nitrogen remover for chicken farm manure treatment, the ammonia nitrogen remover comprises the following raw materials by weight: 18 parts of poplar leaves, 6 parts of cabbage leaves, 4 parts of potassium dihydrogen phosphate, 4 parts of nitrifying bacteria culture liquid, 10 parts of lactic acid bacteria, 2 parts of brown sugar, 1 part of surfactant, 2 parts of lubricant, 20 parts of distilled water.

[0021] The preparation method of the ammonia nitrogen remover comprises the following steps:

[0022] S1: Preparation of organic matter fermentation liquid: Weigh 18 parts of poplar leaves and 6 parts of cabbage leaves in a ratio of 3:1, wash and mix 18 parts of poplar leaves and 6 parts of cabbage leaves, put them into a container, and weigh 2 Parts of brown sugar, 10 parts of lactic acid bacteria and 20 parts of distilled water, and 2 parts of brown sugar, 10 parts of lactic acid bacteria and 20 parts of distilled water are added in the above-mentioned conta...

Embodiment 2

[0028] The ammonia nitrogen remover comprises the following raw materials by weight: 22.5 parts of poplar leaves, 7.5 parts of cabbage leaves, 5 parts of potassium dihydrogen phosphate, 5 parts of nitrifying bacteria culture liquid, 12 parts of lactic acid bacteria, 2.5 parts of brown sugar, 2 parts of surfactant, 3 parts of lubricant, 25 parts of distilled water.

[0029] The preparation method of the ammonia nitrogen remover comprises the following steps:

[0030] S1: Preparation of organic fermentation liquid: Weigh 22.5 parts of poplar leaves and 7.5 parts of cabbage leaves in a ratio of 3:1, wash 22.5 parts of poplar leaves and 7.5 parts of cabbage leaves, and mix them, put them into a container, and weigh 2.5 parts of cabbage leaves. Parts of brown sugar, 12 parts of lactic acid bacteria and 25 parts of distilled water, and 2 parts of brown sugar, 12 parts of lactic acid bacteria and 25 parts of distilled water are added in the above-mentioned container after stirring, a...

Embodiment 3

[0036] The ammonia nitrogen remover comprises the following raw materials by weight: 27 parts of poplar leaves, 9 parts of cabbage leaves, 6 parts of potassium dihydrogen phosphate, 6 parts of nitrifying bacteria culture liquid, 15 parts of lactic acid bacteria, 3 parts of brown sugar, 3 parts of surfactant, 5 parts of lubricant and 30 parts of distilled water.

[0037] The preparation method of the ammonia nitrogen remover comprises the following steps:

[0038] S1: Preparation of organic fermentation liquid: Weigh 27 parts of poplar leaves and 9 parts of cabbage leaves in a ratio of 3:1, wash 27 parts of poplar leaves and 9 parts of cabbage leaves, mix them, put them into a container, weigh 3 parts Parts of brown sugar, 15 parts of lactic acid bacteria and 30 parts of distilled water, and 3 parts of brown sugar, 15 parts of lactic acid bacteria and 30 parts of distilled water are added in the above-mentioned container after stirring, and the fermentation is carried out for 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com