Mycorrhizal inoculant and preparation method thereof

A technology for mycorrhizal inoculants and strains, applied in the field of mycorrhizal inoculants and their preparation, can solve problems such as low utilization rate of chemical fertilizers, low quality survival rate of vegetables, melons and fruits, and achieve excellent traits, promote rapid reproduction, and improve survival. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

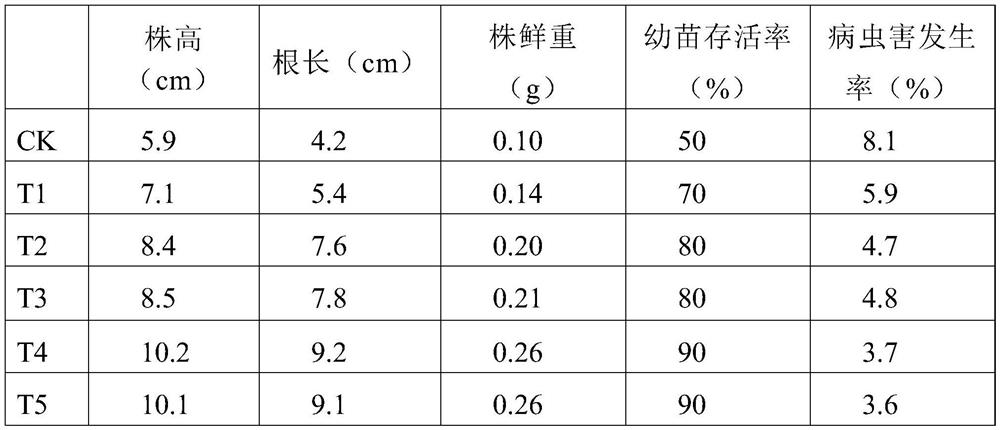

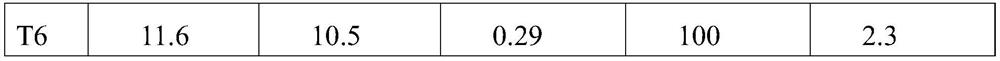

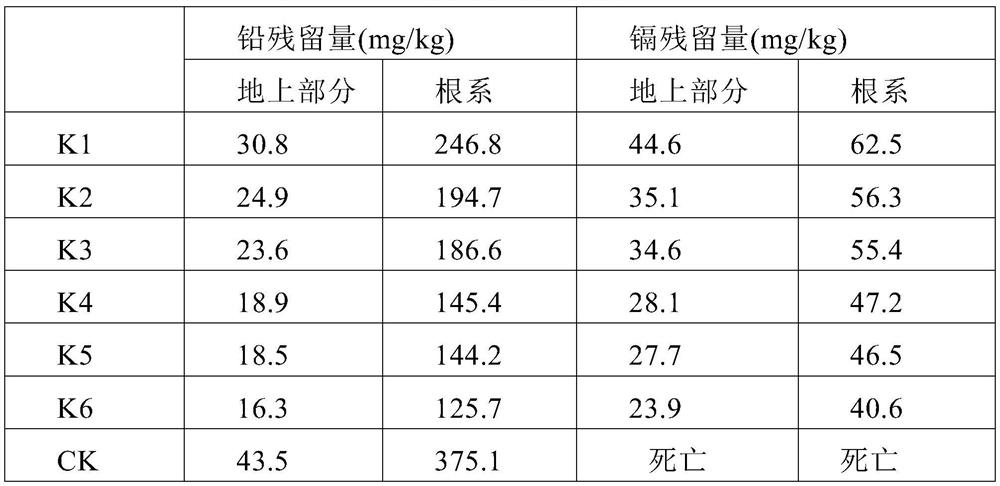

Examples

Embodiment 1

[0034] A preparation method of mycorrhizal agent, comprising the following steps:

[0035] S1. Strain propagation: Mix 10 parts by weight of distilled water, 20 parts by weight of wheat bran, 6 parts by weight of ammonium molybdate, 2 parts by weight of sodium tripolyphosphate, and 3 parts by weight of glucose, sterilize at 121°C for 30 minutes, and cool Obtain the expansion medium, inoculate the bacteria and Sudan grass seeds, and culture aseptically in a plant tissue culture bottle at a temperature of 30°C for 4 weeks, and take the roots and culture medium as the expansion bacteria; the inoculation amount of the bacteria is liquid culture 1wt% of the base mass, the Sudan grass seed is 2wt% of the liquid culture medium quality;

[0036]S2. Preparation: Add the multiplication bacteria into the solid medium and mix evenly. The addition of the multiplication bacteria is 20wt% of the solid medium, sow the Sudan grass seeds, and the content of the Sudan grass seeds is the solid me...

Embodiment 2

[0039] Basically the same as Example 1, the difference is only: the vermiculite powder is replaced by activated vermiculite powder;

[0040] The activated vermiculite powder is prepared according to the following method: put 50 parts by weight of vermiculite powder into a rotating frying pan with a temperature of 70° C. and fry it at a constant temperature for 20 minutes, take it out, and immerse it in 100 parts by weight of 6wt% glucose aqueous solution for 30 minutes. Ultrasonic treatment with a power of 130W and a frequency of 25kHz for 30 minutes, filtering, placing the precipitate in a muffle furnace, heating to 800°C and calcination for 2 hours, then taking it out to obtain activated vermiculite powder.

Embodiment 3

[0042] It is basically the same as in Example 1, the only difference is that the perlite particles are replaced by activated perlite particles;

[0043] The activated perlite particles are prepared according to the following method: 50 parts by weight of perlite particles are added to 150 parts by weight of a 15% citric acid aqueous solution, ultrasonically washed at 200W and 25kHz for 2 hours, then transferred into a Buchner funnel, filtered and washed with distilled water After 30 minutes, the suction filtration product was dried and pulverized and passed through a 100-mesh sieve to obtain purified perlite particles; take all the purified perlite particles, add 150 parts by weight of an activator with a mass fraction of 3%, and immerse in a temperature of 40 ° C. Soak in heat preservation for 2 hours, filter, place the precipitate in a muffle furnace, heat up to 450°C, heat preservation and calcining for 1 hour, then take it out to obtain activated perlite particles;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com