Liquid bacterial fertilizer prepared from pig farm biogas mud and preparation method and application method thereof

A technology for pig farms and liquid bacteria, which is applied in the field of liquid bacterial fertilizer prepared from pig farm biogas sludge and its preparation, which can solve the problem of large one-time investment, difficult to achieve biogas sludge disposal efficiency, and lack of resource treatment and cleaning Agricultural applications and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

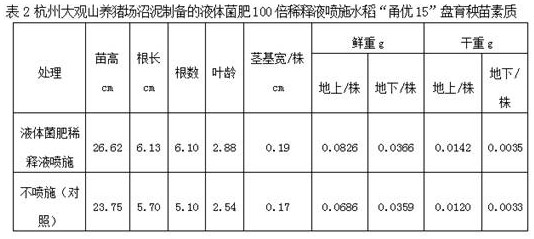

[0037] Example 1: 50% of biogas slurry in the biogas slurry fermentation tank of Hangzhou Daguanshan Pig Breeding Co., Ltd., 2% of glucose carbon source, 0.5% of EM bacterial agent, and 47.5% of tap water; the temperature is 30°C, and the underwater stirrer is the preparation container The flow rate of the oxygenator is 150%, the flow rate of the oxygenator into the preparation container is 250% of the preparation container, and the cultivation time is 10 days to form a sol-like bacterial fertilizer, which is the final product.

example 2

[0038] Example 2: 50% of biogas sludge, 2% of brown sugar, 0.5% of EM bacterial agent, and 47.5% of river water in the biogas slurry fermentation tank of the pig farm of Hangzhou Daguanshan Pig Breeding Co., Ltd.; the temperature is 30°C, and the flow rate of the underwater stirrer is the preparation container 100%, the aeration flow rate of the oxygenator into the preparation container is 250% of the preparation container, and the cultivation time is 15 days to form a sol-like bacterial fertilizer, which is the final product.

example 3

[0039] Example 3: 45% biogas sludge, 2% rice bran, 0.5% bacillus agent, and 47.5% river water in the biogas slurry fermentation tank of the pig farm of Hangzhou Daguanshan Pig Breeding Co., Ltd.; the temperature is 30°C, and the flow rate of the underwater stirrer is the preparation container 200%, the aeration flow rate of the oxygenator into the preparation container is 250% of the preparation container, and the cultivation time is 30 days to form a sol-like bacterial fertilizer, which is the final product.

[0040] The swamp mud is the sediment after the pig farm manure is fermented in a fermenter or a fermenter. The carbon source is one or more mixtures of glucose, brown sugar, starch, rice bran and bran. The aerobic fermentation bacteria agent is bacillus, EM bacteria, rhizobia bacteria agent, nitrogen-fixing bacteria agent, phosphorus-solubilizing microbial agent, silicate microbial agent, photosynthetic bacteria agent, organic material decomposing agent, growth-promotin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com