Lactic acid bacteria agent for fermenting soybean protein, preparation method, fermentation method, fermentation product with muscle-enhancing function

A technology for soybean protein and hydrolyzed soybean protein, which is applied in the field of deep food processing, can solve the problems of poor flavor and taste of soybean protein, restrict the wide application of soybean protein, etc., so as to be beneficial to human body absorption, improve edibility and nutritional value, and improve taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

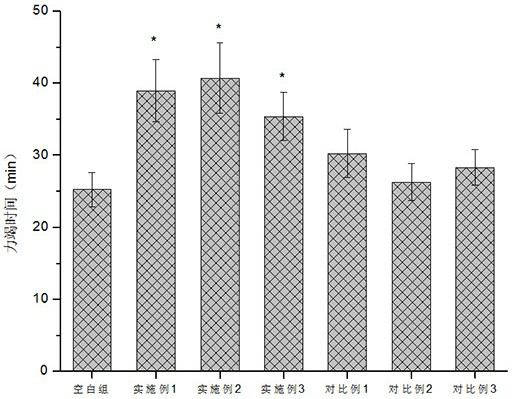

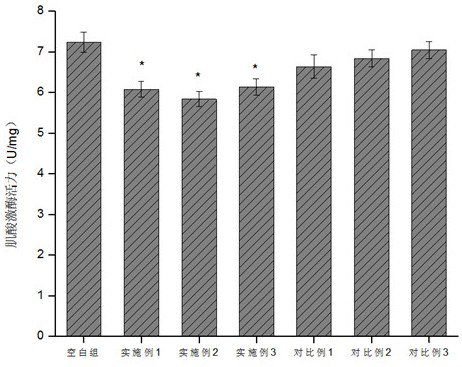

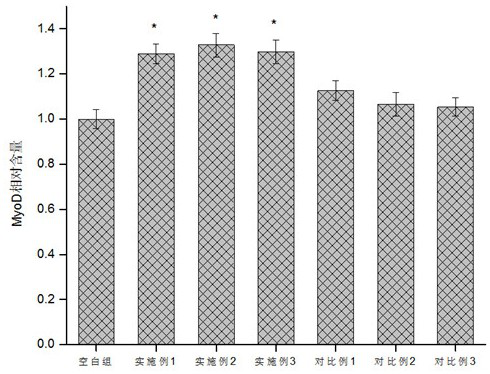

Examples

Embodiment 1

[0065] Step 1. Mix soybean protein (Xi'an Haotian Bioengineering Co., Ltd., protein (dry basis) ≥ 90.0g / 100g) and water at a mass ratio of 1:5, add 1.5‰ of papain, and heat at 50°C Under enzymatic hydrolysis for 1 hour, hydrolyzed soybean protein was obtained;

[0066] Weigh 20g of hydrolyzed soybean protein, 10g of sucrose, 1.5g of magnesium sulfate, 2g of dipotassium hydrogen phosphate, 7.5g of sodium acetate, and 10g of calcium carbonate, and prepare 1L of liquid medium;

[0067] Step 2. Inoculate Lactobacillus plantarum, Pediococcus pentosaceae, Lactobacillus paracasei and Lactobacillus fermentum into the above-mentioned liquid medium respectively, and ferment at 37°C for 18 hours. After the fermentation, the mass ratio of viable bacteria is 1.0:1.0 :1.5:0.5 to collect bacteria;

[0068] Step 3. Weigh 5g of bacteria and 10g of protective agent, mix evenly, and vacuum freeze-dry to obtain lactic acid bacteria agent, wherein, the protective agent includes 5% skimmed milk po...

Embodiment 2

[0072] The preparation method of the lactic acid bacteria inoculum provided by the present embodiment comprises the steps:

[0073] Step 1. Mix soybean protein (Henan Kunhua Biological Company, protein (dry basis) ≥ 88.0g / 100g) and water according to the mass ratio of 1:6, add 1.0‰ of neutral protease, 52 ℃ Under enzymatic hydrolysis for 1 hour, hydrolyzed soybean protein was obtained;

[0074] Weigh 20g of hydrolyzed soybean protein, 10g of sucrose, 1.5g of magnesium sulfate, 2g of dipotassium hydrogen phosphate, 7.5g of sodium acetate, and 10g of calcium carbonate, and prepare 1L of liquid medium;

[0075] Step 2. Inoculate Lactobacillus helveticus and Lactobacillus salivarius into the above-mentioned liquid medium respectively, ferment at 37°C for 20 hours, and collect the bacterial cells according to the mass ratio of the number of viable bacteria at 1.0:1.5 after fermentation;

[0076] Step 3. Weigh 5g of bacteria and 10g of protective agent, mix evenly, and vacuum freez...

Embodiment 3

[0080] The preparation method of the lactic acid bacteria inoculum provided by the present embodiment comprises the steps:

[0081] Step 1. Mix soybean protein (Shandong Jinluo Enterprise Group Corporation, protein (dry basis) ≥ 85.0g / 100g) and water according to the mass ratio of 1:4, add 1.5‰ of acid protease, 53 ℃ Under enzymatic hydrolysis for 1 hour, hydrolyzed soybean protein was obtained;

[0082] Weigh 20g of hydrolyzed soybean protein, 10g of sucrose, 1.5g of magnesium sulfate, 2g of dipotassium hydrogen phosphate, 7.5g of sodium acetate, and 10g of calcium carbonate, and prepare 1L of liquid medium;

[0083] Step 2. Inoculate Lactobacillus plantarum, Lactobacillus helveticus and Pediococcus pentosacea into the above liquid medium respectively, ferment at 37°C for 18 hours, and collect the cells according to the mass ratio of the number of viable bacteria at 1.0:1.5:0.5 after fermentation ;

[0084] Step 3. Weigh 5g of bacteria and 10g of protective agent, mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com