Deoiling and degreasing powder and preparation method thereof

A technology for degreasing and degreasing powder and degreasing powder, which is applied in the direction of metal material coating process, etc., can solve the problems of incomplete removal, easy rust of metal parts, and poor rust resistance, so as to reduce the difficulty of cleaning and maintenance, and achieve efficient cleaning. , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

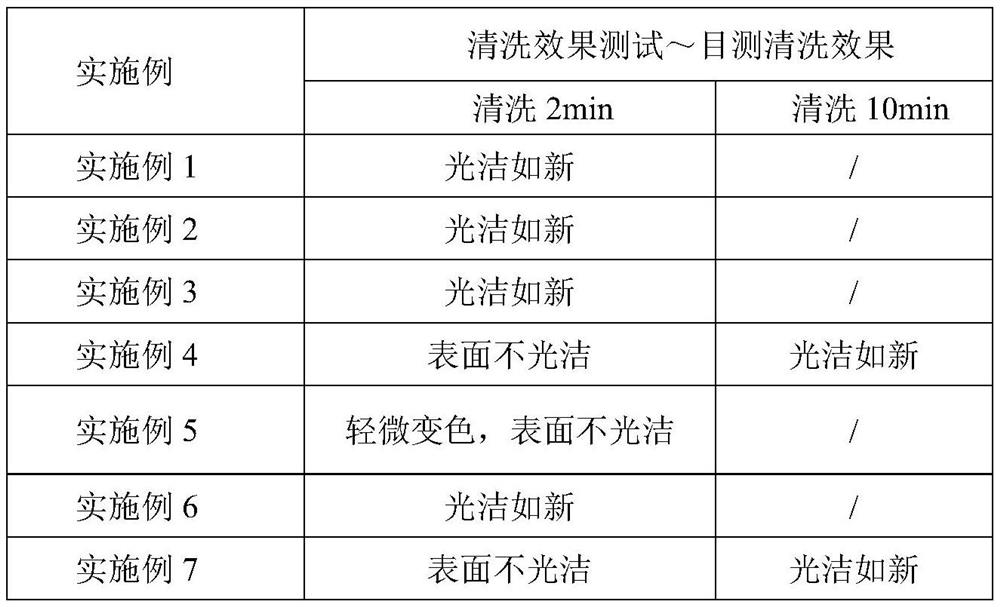

Examples

preparation example Construction

[0068] A preparation method for degreasing and degreasing powder, comprising the following steps:

[0069] S1. Add 24-32 parts of basic compounds, 40-50 parts of inorganic salts, and 4-6 parts of additives into the mixer for dispersion, mix and disperse for 0.5-3 minutes to form mixture A; the dispersion speed of the mixer is 500-800r / min ;

[0070] S2. Add 11-19 parts of chelating agent and 6-10 parts of surfactant into the mixer for dispersion, mix and disperse for 1-5 minutes to form mixture B; the dispersion speed of the mixer is 500-800r / min;

[0071] S3. Mix and stir the mixture A and the mixture B for 1-3 minutes to obtain degreasing and degreasing powder; the dispersing speed of the mixer is 500-800 r / min.

[0072] Further, a preparation method of degreasing and degreasing powder comprises the following steps:

[0073] S1. Add 14 to 18 parts of potassium hydroxide, 10 to 14 parts of sodium hydroxide, 40 to 50 parts of sodium carbonate, and 4 to 6 parts of sodium perc...

Embodiment 1

[0078] A degreasing and degreasing powder, comprising the following raw materials in parts by weight: 15 parts of potassium hydroxide, 12 parts of sodium hydroxide, 45 parts of sodium carbonate, 5 parts of sodium percarbonate, 10 parts of sodium citrate, maleic acid acrylic acid copolymer 5 parts of sodium salt, 4.8 parts of cocoic acid monoethanolamide, and 3.2 parts of cetyltrimethylammonium chloride.

[0079] The maleic acid and acrylic acid copolymerized sodium salt was purchased from Shanghai Beizhuo Biotechnology Co., Ltd., with a CAS number of 26677-99-6.

[0080] The sodium citrate was purchased from Shaanxi Chenming Biotechnology Co., Ltd., with a CAS number of 68-04-2.

[0081] The cetyltrimethylammonium chloride was purchased from Shanghai Xuejie Chemical Co., Ltd., with a CAS number of 112-02-7.

[0082] The cocoic acid monoethanolamide is purchased from Zhaoqing Huada Washing Raw Material Factory, and the CAS number is 68140-00-1.

[0083] A preparation method f...

Embodiment 2

[0088] A degreasing and degreasing powder, comprising the following raw materials in parts by weight: 18 parts of potassium hydroxide, 14 parts of sodium hydroxide, 50 parts of sodium carbonate, 6 parts of sodium percarbonate, 12 parts of sodium citrate, maleic acid acrylic acid copolymer 7 parts of sodium salt, 6 parts of cocoic acid monoethanolamide, 4 parts of cetyltrimethylammonium chloride.

[0089] The maleic acid and acrylic acid copolymerized sodium salt was purchased from Shanghai Beizhuo Biotechnology Co., Ltd., with a CAS number of 26677-99-6.

[0090] The sodium citrate was purchased from Shaanxi Chenming Biotechnology Co., Ltd., with a CAS number of 68-04-2.

[0091] The cetyltrimethylammonium chloride was purchased from Shanghai Xuejie Chemical Co., Ltd., with a CAS number of 112-02-7.

[0092] The cocoic acid monoethanolamide is purchased from Zhaoqing Huada Washing Raw Material Factory, and the CAS number is 68140-00-1.

[0093] A preparation method for degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com