Current collector modification method, and modified current collector and application thereof

A current collector and modification technology, applied in the field of current collector modification research, can solve the problem of high cost of current collector modification, and achieve the effects of low cost of raw materials, long cycle life, and easy commercial promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] As an embodiment of the embodiment of the present invention, the alkali metal amino salt is any of the following: amino sodium, aminol.

[0043] In the present invention, in order to increase the efficiency of the reaction, the metal oxide can be mixed with an alkali metal amino salt after a mortar for 5-15 min to ablate.

[0044] S2, configure the metal nitride into suspension;

[0045] As an embodiment of the embodiment of the present invention, the suspension has a solid content of 10-30 mg · ml. -1 .

[0046] The addition of metal nitrides has a general meeting to make the dissolved dispersion process cannot obtain uniform suspension, which is easy to reunite, and the subsequent evaporation crystal process will also be uneven in the surface of the collector; the addition of metal nitrides is too small, so that the current fluid load The nitride content is less, and the subsequent performance test will result in a bad result.

[0047] As an embodiment of the embodiment o...

Embodiment 1

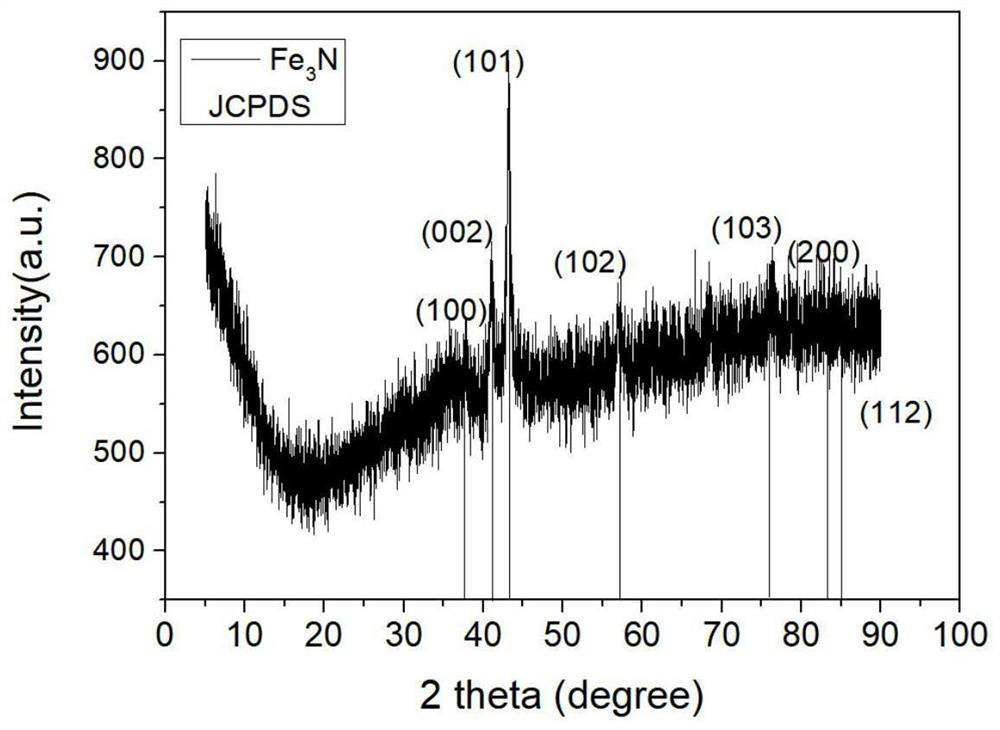

[0060] 1. Commercial triodoxide powder and flaky amino sodium (Nanh 2 Mass mole is grinded by 5 min in a mortar, placing the mixture in a porcelain and placed in a tubular furnace, protecting the gas nitrogen, and the temperature rise rate is 2 ° C · min -1 The holding temperature is 290 ° C, 3 hours.

[0061] 2, the tube furnace is lowered to the room temperature, take out the porcelain boat, and slowly add a small amount of deionized water with alcohol to fully react with excess aminometh, collect the product, deionized water is solvent. Three centrifugations, after alcohol was centrifuged twice, the rotational speed was 8000 rpm, the time was 3 min, and the iron nitride powder was obtained.

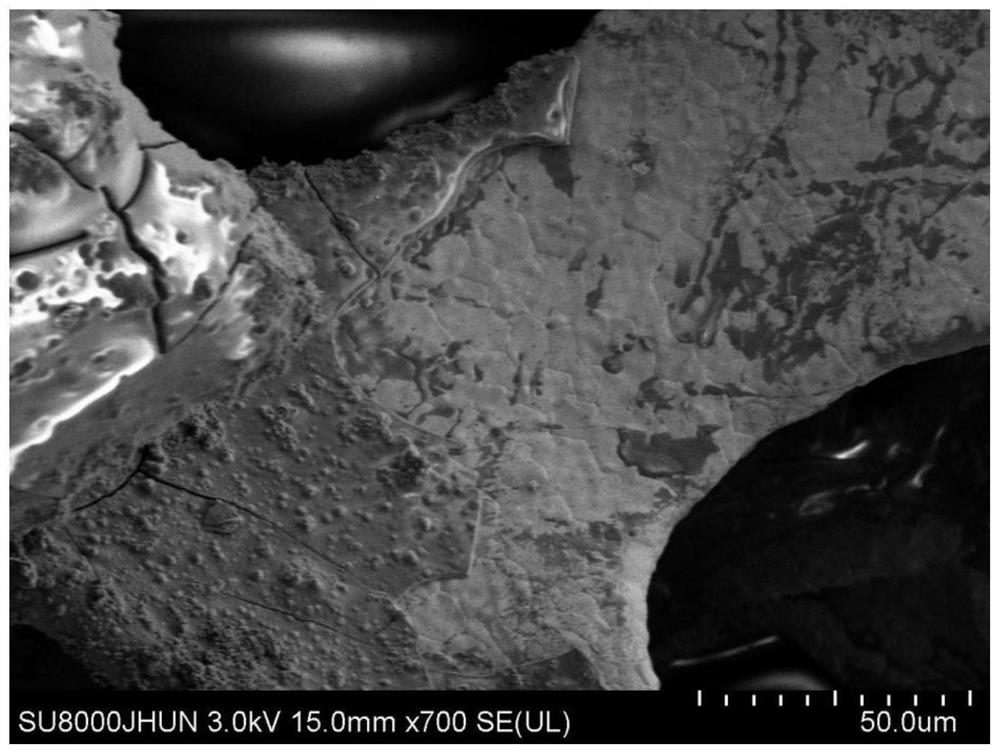

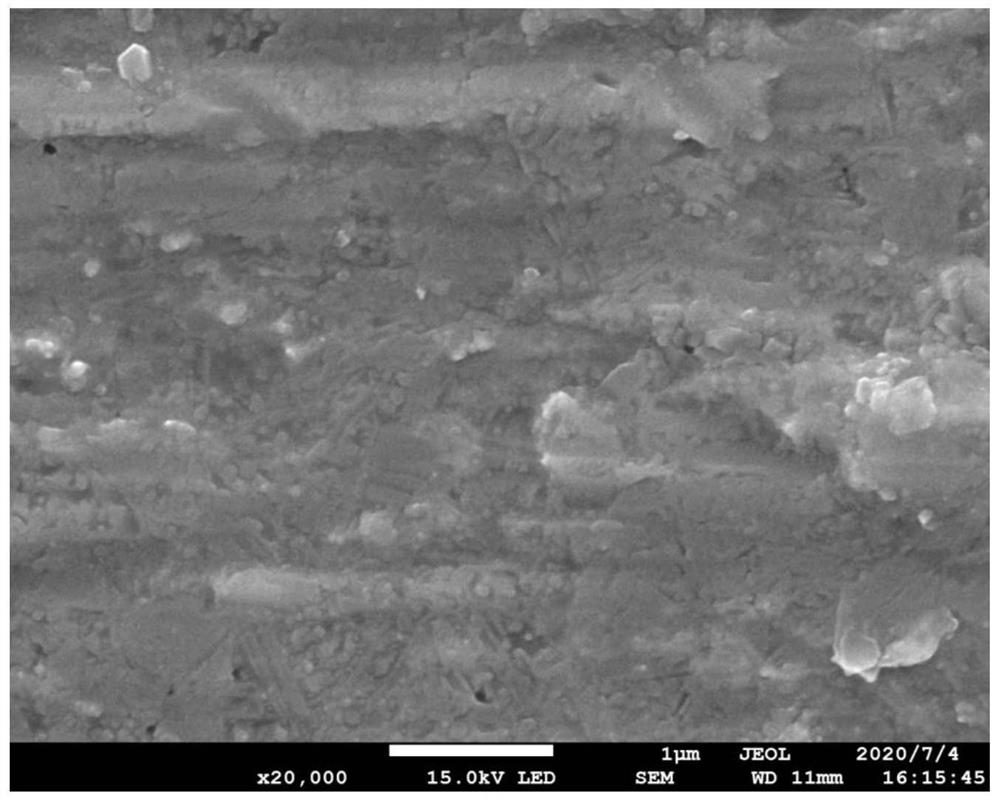

[0062] 3. Place the nitride powder obtained by step 2 into alcohol, configure the solid content of 10 mg ml -1 The suspension, and the suspension is subjected to a clean glass dish by ultrasound, and then pour the silicon nanoparticles into a clean glass dish, and the foam of the three pun...

Embodiment 2

[0065] 1, commercial iron oxide powder (Fe 3 O 4 ) With aminomide (linh 2 The mass rather than 1: 2 is grinded in a mortar for 15 min, and the mixture is placed in a porcelain-cavalu and placed in a tubular furnace, and the protective gas is argon, and the temperature rise rate is 10 ° C · min. -1 The holding temperature and time were 350 ° C, 6 hours.

[0066] 2. Tube-tube furnace is lowered to room temperature, take out the porcelain boat, slowly add a small amount of deionized water with alcohol, and collect the excess of excess aminol, collect the product, deionized water is a solvent. Three centrifugation, after the solvent was centrifuged with alcohol twice, the rotational speed was 10,000 rpm, the time was 5 min, and the iron nitride powder was obtained.

[0067] 3. Place the nitride powder at step 2 in N, N-dimethylformamide, configured to solidify the suspension of 30 mg / ml, and sufficiently adequately mixing the suspension through the ultrasound. After the dispersion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com