Glass through hole processing method

A processing method and technology of through-glass holes, applied in the field of microelectronic packaging, can solve the problems of low efficiency, easy occurrence of micro-cracks, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

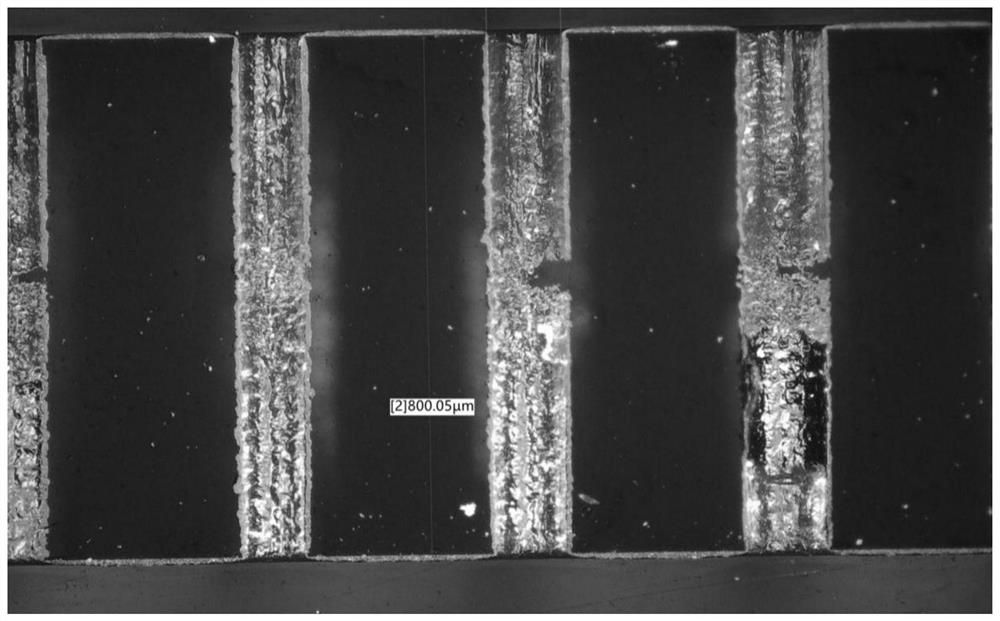

[0044] (1) Glass cleaning: put the flat glass 1 to be processed into a NaOH solution with a solubility of 12% and ultrasonically clean it for 20 minutes, then rinse it with deionized water for 20 minutes, and dry it at 120° C. for 1 hour.

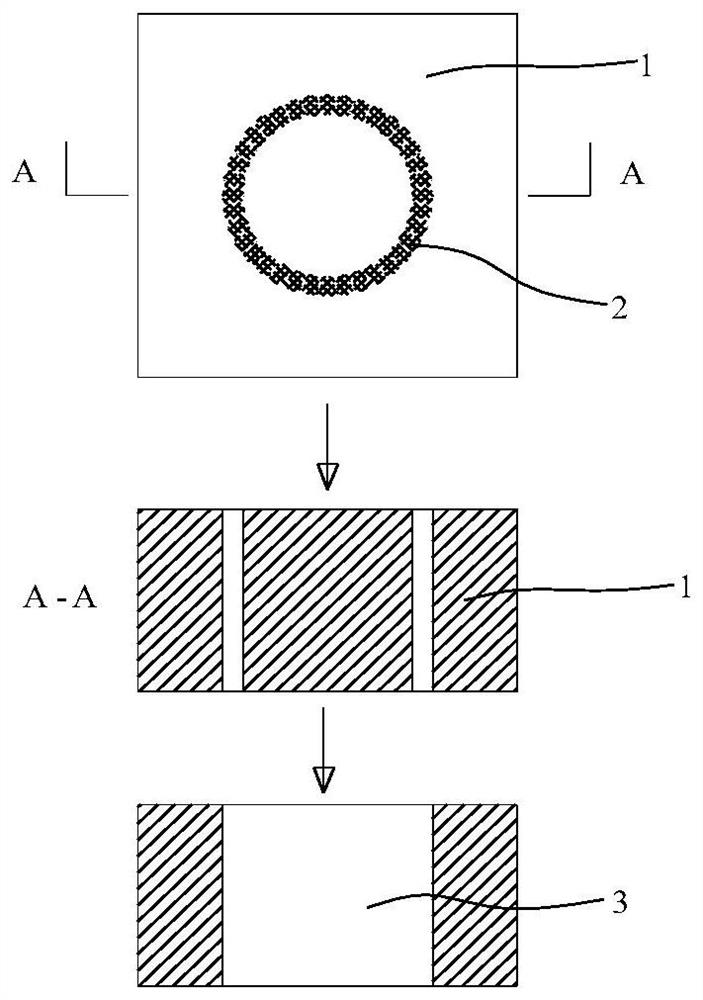

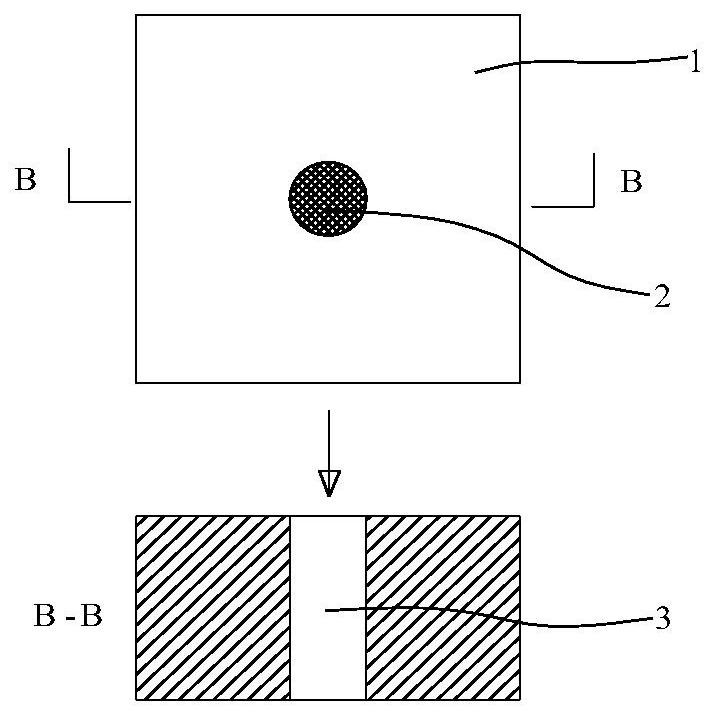

[0045] (2), laser modification: delineate the area of the plate glass to be opened as the target area 2, then place the plate glass 1 under the titanium sapphire femtosecond laser, the pulse energy is 2uJ, and the laser scanning speed is 0.35mm / s, The target area 2 is irradiated circularly to modify the glass in the target area.

[0046] (3) Glass etching: Add 0.5 parts by weight of octylphenyl polyoxyethylene to 2 parts by weight of absolute ethanol, stir evenly and let it stand for 1 hour until the foam disappears, and prepare a surface active compound ;

[0047] Add 10 parts by weight of 40wt.% hydrofluoric acid to 100 parts by weight of pure water, then add 10 parts by weight of 50wt.% sulfuric acid and 2 parts by weight of potassium...

Embodiment 2

[0051] The present embodiment is basically the same as the above-mentioned embodiment one, the difference is the preparation of the surface-active compounding agent in the step (3):

[0052] Add 0.5 parts by weight of cetyltrimethylammonium chloride into 2 parts by weight of absolute ethanol, stir evenly, and then let stand for 1 hour until the foam disappears to prepare a surface active compound.

Embodiment 3

[0054] The present embodiment is basically the same as the above-mentioned embodiment one, the difference is the preparation of the surface-active compounding agent in the step (3):

[0055] Add 0.5 parts by weight of sodium α-alkenyl sulfonate to 2.5 parts by weight of absolute ethanol, stir evenly, and then let stand for 1 hour until the foam disappears to prepare a surface active compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com