Wood-based carbon foam and preparation method thereof, cathode electrocatalyst, cathode and metal-air battery

A carbon foam and wood-based technology, applied in the preparation/purification of carbon, electrical components, battery electrodes, etc., can solve the problems of limited industrial application, complicated preparation process of porous carbon materials, high production cost, etc. Industrial application prospect, effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] According to a first aspect of the present invention, a preparation method of wood-based carbon foam is provided, comprising the following steps:

[0069] (a) providing delignified wood;

[0070] providing a first solution formed of a transition metal salt, a heteroatom compound and a solvent;

[0071] Wherein, the transition metal salt includes iron salt and cobalt salt, and the heteroatom compound includes nitrogen-containing compound;

[0072] (b) mixing the delignified wood with the first solution, followed by solid-liquid separation to obtain a wood precursor;

[0073] The air in the wood precursor is removed to make the wood precursor porous, then low-temperature solidification and freeze-drying are performed to obtain wood-based foam;

[0074] (c) pyrolyzing the wood-based foam in an inert atmosphere to obtain a wood-based carbon foam.

[0075] Specifically, delignified wood means that the wood does not contain lignin, and "free" means that the amount of ligni...

Embodiment approach

[0083] As an optional embodiment of the present invention, in step (a), the preparation method of delignified wood comprises the following steps:

[0084] provide a solution containing a lignin remover;

[0085] The wood is mixed with a solution containing a lignin remover to cause a reaction, and after the reaction is completed, solid-liquid separation is performed, and the separated solid is placed in an oxidizing solution for treatment to obtain de-lignined wood.

[0086] The wood reacts with the solution containing the lignin remover, and the lignin in the wood can be degraded by the above solution (mainly the lignin remover), thereby realizing the removal of lignin from the wood. After the reaction is completed, in order to prevent lignin from remaining in the wood, the separated solids are placed in an oxidizing solution to further remove residual lignin.

[0087] By limiting the preparation method of delignified wood, the lignin can be more fully removed, the removal o...

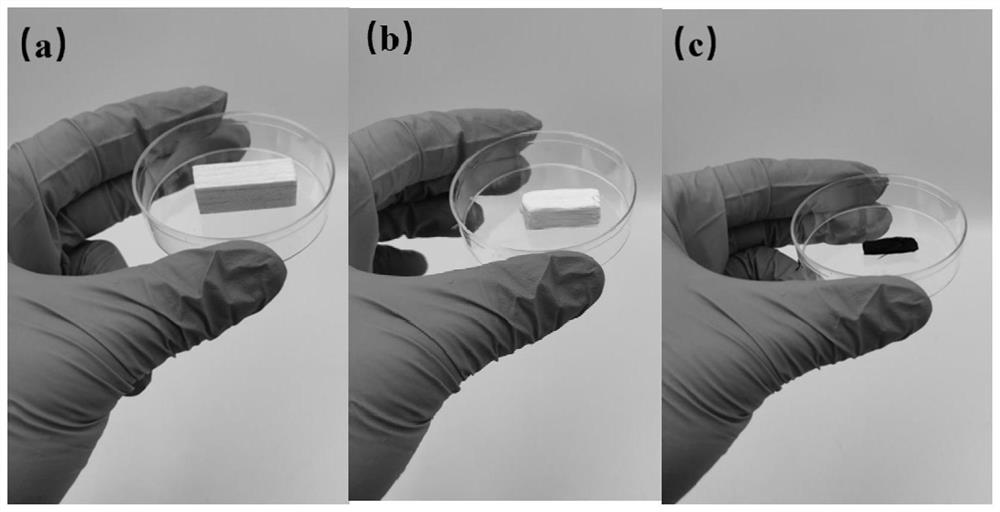

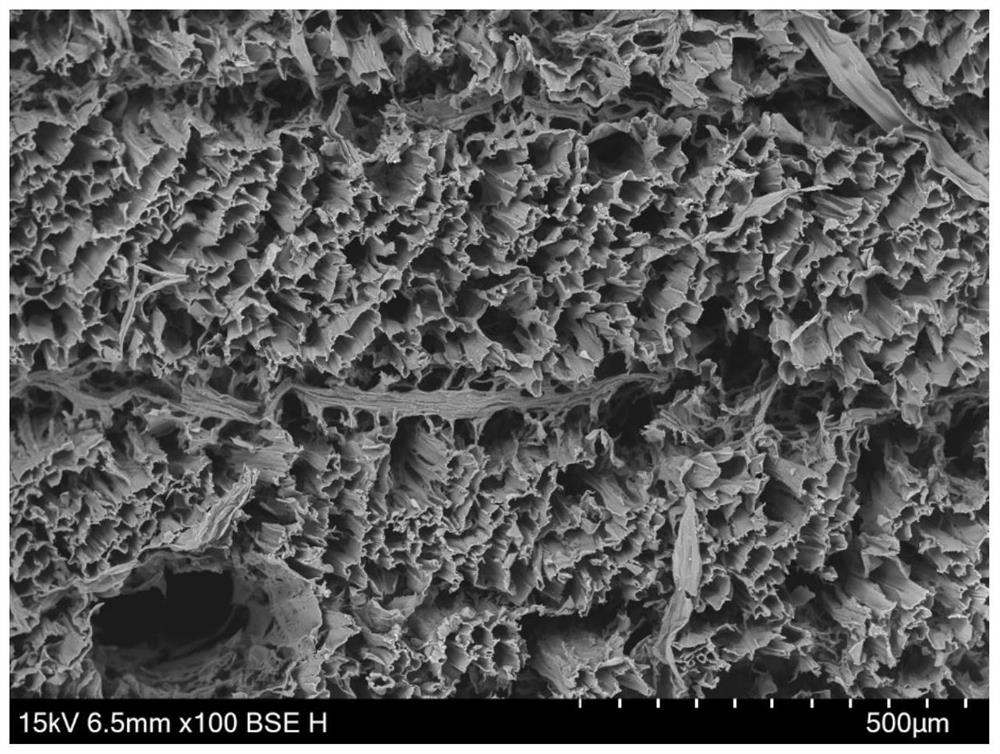

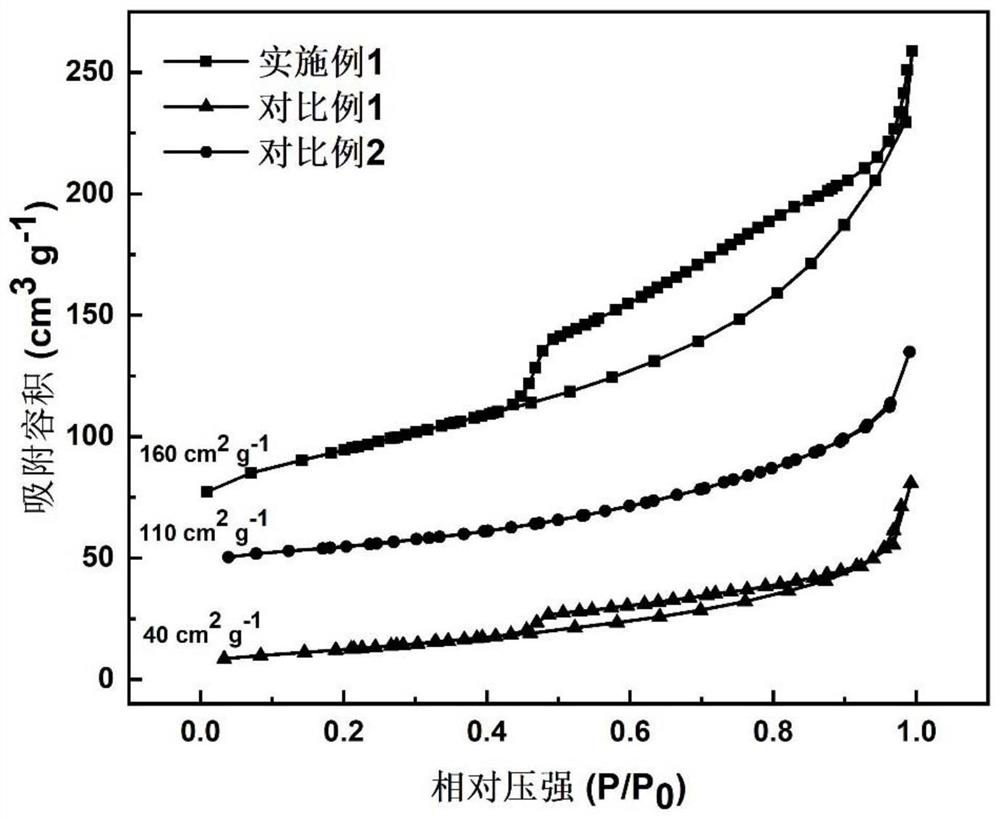

Embodiment 1

[0137] The preparation method of the wood-based carbon foam provided by the present embodiment comprises the following steps:

[0138] (a) providing delignified wood;

[0139] 1g of wood (Barr fir) was placed in a 100mL polytetrafluoroethylene reactor, and then 50mL of an aqueous solution containing a lignin removing agent was added, wherein the lignin removing agent included KOH (2.5mol / L) and Na 2 SO 3 (0.4mol / L), the reaction temperature was controlled to be 160°C for 10h, and the solid-liquid separation was carried out after the reaction, and the separated solid was placed in boiling hydrogen peroxide for 2h, and then rinsed in hot deionized water for several times to remove Residual chemicals, resulting in delignified wood;

[0140] providing a first solution of transition metal salt, heteroatom compound and ethanol;

[0141] Wherein, the transition metal salt includes 0.1 g of ferric chloride hexahydrate and 0.107 g of cobalt nitrate hexahydrate, and the heteroatom co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com