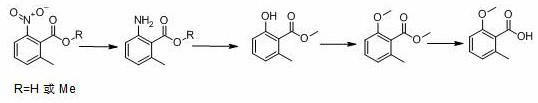

Preparation method of 2-methoxy-6-methylbenzoic acid

A kind of technology of methyl benzoic acid and methyl benzoate is applied in the field of preparation of 2-methoxy-6-methyl benzoic acid, and can solve the difficulty of 2-methoxy-6-methyl benzoic acid source , the lack of reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Reductive hydrogenation

[0035] Add 2-methyl-6-nitrobenzoic acid (500 g), platinum carbon (platinum content: 2%, 50 g), methanol (2000 g), into the autoclave, replace with nitrogen, and pass hydrogen to a pressure of 1.0-1.3 MPa, raise the temperature to 70-80°C, control the temperature and control the reaction pressure until the reaction is complete (raw material <0.5%), continue to stir for 60 min, filter while hot, collect the catalyst for mechanical use, and directly carry out diazotization hydrolysis of the mother liquor.

[0036] (2) Diazotization hydrolysis

[0037] The temperature of the reduction mother liquor obtained in step (1) is lowered to 0-5°C, and 900 g of nitrosyl sulfuric acid (weight percentage: 40%, 1.02 eq.) is added dropwise under temperature control. 30min, after stirring for 1 hour, heat up to 64-66°C and reflux for 8-12 hours until the reaction is complete (HPLC: 2-hydroxy-6-methylbenzoic acid+2-methoxy-6-methylbenzoic acid<1 %).

[003...

Embodiment 2

[0046] (1) Reductive hydrogenation

[0047] Add 2-methyl-6-nitrobenzoic acid (450 g), platinum carbon (platinum content: 2%, 9.0 g), methanol (1350 g), into the autoclave, nitrogen replacement, and hydrogen pressure to 0.9-1.1 MPa, raise the temperature to 60-70°C, control the temperature and control the reaction pressure until the reaction is complete (raw material <0.5%), continue to stir for 30 min, filter while hot, divide the mother liquor into three parts while hot, and directly carry out diazotization hydrolysis.

[0048] (2) Diazotization hydrolysis

[0049] The reduction mother liquor (1 / 3 amount) obtained in step (1) is cooled to 5-10°C, and 317.3 g of nitrosyl sulfuric acid (mass concentration 40%, 1.2 eq.) is added dropwise under temperature control. After the addition is completed, the temperature is slowly raised to 50-60 ℃, control the heating time not less than 30min, after stirring for 1 hour, raise the temperature to 64-66℃ and reflux for 12-16 hours until t...

Embodiment 3

[0055] diazotization hydrolysis

[0056] The reduction mother liquor (1 / 3 amount) obtained in step (1) of Example 2 was cooled to 10-15°C, and 277.6 g of sodium nitrite solution (mass concentration 40%, 1.05 eq.) was added dropwise under temperature control, and the addition was completed slowly Raise the temperature to 50-60°C, stir for 1 hour, then raise the temperature to 64-66°C and reflux for 8-16 hours until the reaction is complete (HPLC: 2-hydroxy-6-methylbenzoic acid + 2-methoxy-6-methyl benzoic acid <1%).

[0057] Raise the temperature to 85-100°C, recover about 360 g of methanol by atmospheric distillation, add 400 g of water, let stand to separate layers, and separate 105 g of oil layer.

[0058] The aqueous layer was extracted with MIBK 100ml, the organic layer was separated and concentrated, and then combined with the oil layer to obtain 141 g of crude product of methyl 2-hydroxy-6-methylbenzoate (HPLC: methyl 2-hydroxy-6-methylbenzoate: 45.6%; 2-methoxy-6-meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com