Collagen bio-ink for 3D printing and 3D printing method

A technology of collagen and bio-ink, which is applied in applications, inks, household appliances, etc., can solve the problems of poor safety, lack, and poor mechanical strength of medical materials, and achieve high safety, simple and gentle preparation methods, and good mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 collagen stock solution

[0042] Wash the yak tendon tissue to remove foreign matter and crush it into small pieces; degrease the crushed small pieces with 10% n-butanol, take the precipitate, wash it with water until neutral; decalcify the precipitate with 0.5M hydrochloric acid solution, After decalcification is completed, take the precipitate and wash it with water until neutral; soak the tissue precipitate in 0.1M sodium hydroxide solution, stir at 25°C for 4 hours, take the precipitate, wash it with water until neutral; use 0.5M pepsin containing 1g / L Collagen was extracted with acetic acid solution to obtain a crude collagen extract; pH was adjusted to neutral for enzyme inactivation; 8-14kDa dialysis bags were dialyzed to obtain collagen stock solutions with a concentration of 6 mg / mL.

Embodiment 2

[0043] 3D printing method one of embodiment 2 collagen bioink

[0044] 2.1 Collagen modified with methacrylic anhydride

[0045] Take the collagen stock solution prepared in Example 1, dilute it to a concentration of 1.5 mg / mL, add 150 mM NaCl and MOPS mixed buffer solution, adjust the pH to 7, and add 1 mL of methacrylic anhydride to every 200 mL of collagen stock solution under nitrogen protection , reacted in an ice bath to obtain a reaction product;

[0046] The reaction product obtained above was dialyzed with a mixed solution of 15 mM HCl and NaCl, and the dialysate was replaced for 6 times, followed by 15 mM HCl solution, and the dialysate was replaced for 5 times to obtain methacrylic anhydride-modified collagen ColMA , placed at -20°C for later use.

[0047] 2.2 Preparation of collagen bioink

[0048] Before use, take the above-mentioned ColMA solution, add photoinitiator LAP solution, until the final concentration of ColMA solution is 1.5 mg / mL, and the final conc...

Embodiment 3

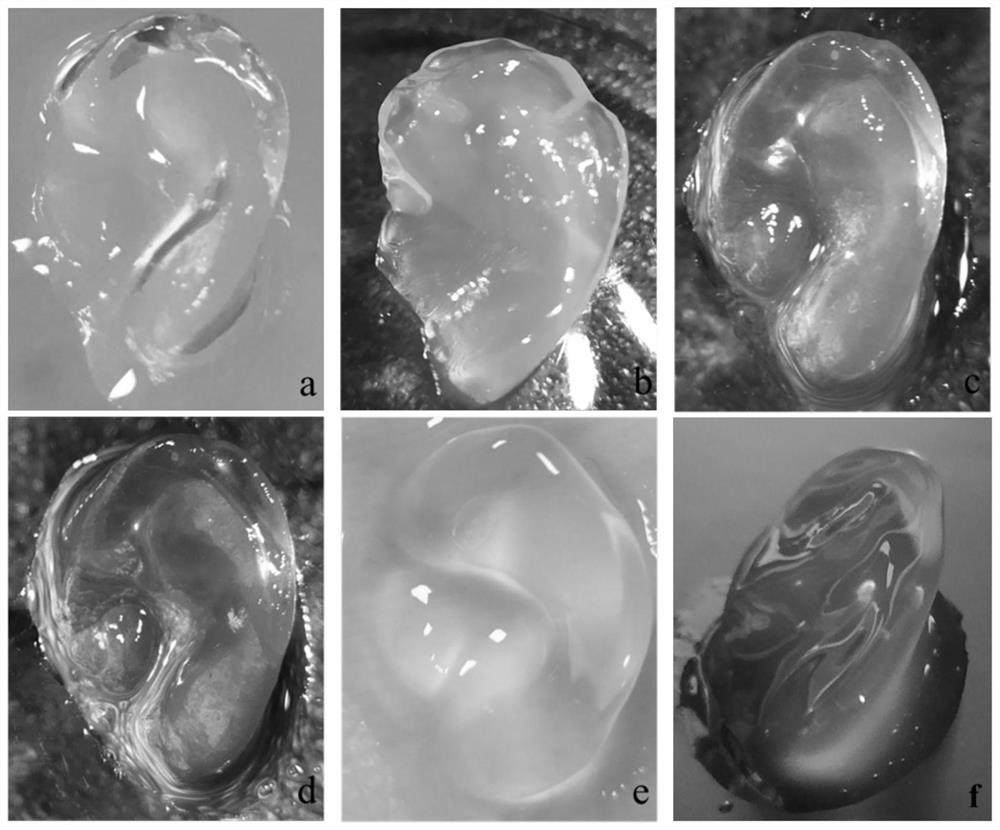

[0050] Add the above configured collagen bio-ink into the light-curing 3D printer, and irradiate it with blue light with a wavelength of 405nm for 12s to perform light-curing 3D printing; after printing, use a blue-light flashlight with a wavelength of 405nm as the light source, with a distance of 5cm and light for 20s , and perform secondary curing to obtain 3D printed medical prosthetic ears. The printed medical prosthetic ears are as follows: figure 1 As shown in a, the prepared collagen bioink has fast curing speed and strong mechanical strength, and can print medical prosthetic ears similar to human ears. 3D printing method two of embodiment 3 collagen bioink

[0051] 3.1 Collagen modified with methacrylic anhydride

[0052] Take the collagen stock solution prepared in Example 1, dilute it to a concentration of 3 mg / mL, add 200 mM NaCl and MOPS mixed buffer solution, adjust the pH to 7, and add 1 mL of methacrylic anhydride to every 200 mL of collagen stock solution unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com