Preparation method of nano-silver/diatomite/calcium alginate composite antibacterial hydrogel microspheres

A hydrogel microsphere and composite antibacterial technology, applied in the field of materials, can solve the problems of easy degradation by bacteria, high production cost, toxicity, etc., achieve good antibacterial effect and enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

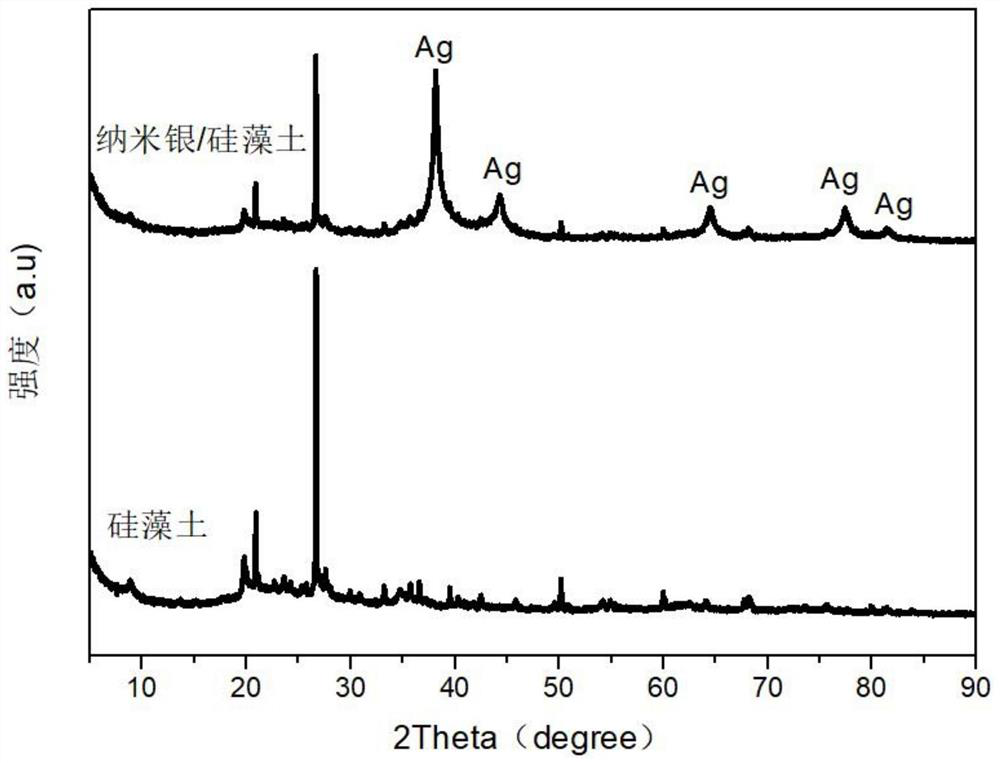

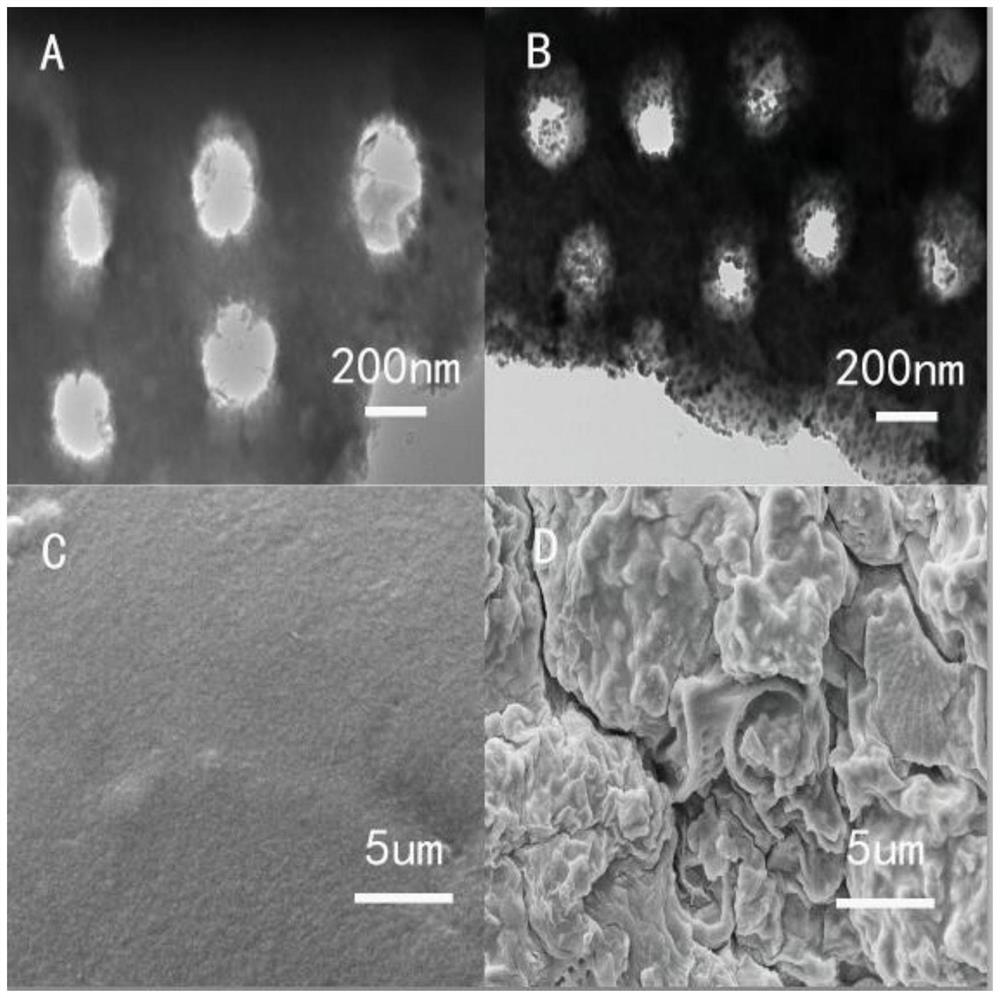

[0031] (2) Preparation of nanosilver loaded on diatomaceous earth: Add silver nitrate (0.1-0.5g) to 10-50ml of absolute ethanol, then use a mechanical stirrer (300rpm) to stir for 2 hours until completely dissolved, add 0.5-3g of silicon Alginate, then ultrasonically disperse for 10-20min, continue to stir for 1 hour to obtain dispersion A, add a certain amount of sodium hydroxide (0.1-0.5g) to the ethanol solution (10-50ml), stir for 1 hour until completely dissolved, Solution B was obtained, and solution B was slowly added to dispersion A, and stirring was continued for 0.5 hours. After the obtained solution is centrifuged-washed-centrifuged, it is dried in a vacuum oven at 30-60° C. for 12 hours to obtain diatomite-based silver nanoparticles.

[0032] (3) Preparation of sodium alginate-embedded nano-silver / diatomite: 0.1-5g of sodium alginate is dissolved in 20-200ml of deionized water, 0.1-5g of diatomite-based nano-silver particles are added, and magnetically stirred for ...

Embodiment 1

[0034] Preparation of nanosilver / diatomaceous earth:

[0035] (1) Purification of natural diatomite: Grind and sieve natural diatomite, take 10g of the powder and add it to hydrochloric acid solution (2mol / L, 500ml) to remove organic and inorganic impurities, then use a magnetic stirrer to continuously stir for 8 hours, and filter through a 400-mesh sieve After netting, the obtained product was washed three times with deionized water, and then dried in an oven at 50 °C.

[0036] (2) Diatomaceous earth-loaded nano-silver: Add silver nitrate (0.2g) to 40 ml of absolute ethanol, then use a mechanical stirrer (200rpm) to stir for 2 hours until completely dissolved, add 1g of diatomaceous earth, and then ultrasonically disperse for 20min, Continue stirring for 1 hour to obtain dispersion A, add a certain amount of sodium hydroxide (0.15g) to ethanol solution (20ml), stir for 1 hour until completely dissolved, obtain solution B, slowly add solution B to dispersion A , and continued...

Embodiment 2

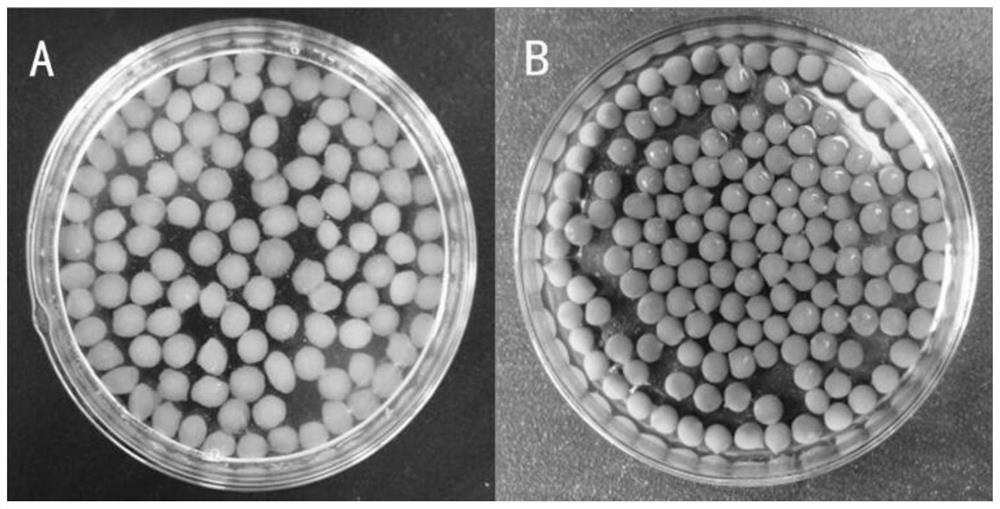

[0039] Preparation of calcium alginate hydrogel microspheres: Dissolve 1g of sodium alginate in 100ml of deionized water, add 1g of diatomaceous earth-based nano-silver particles, stir magnetically for 0.5h, use a 10ml syringe, drop it into chlorine at a constant speed Calcium chloride aqueous solution (20mg / L, 100ml), the solidified gel beads were filtered out to obtain calcium alginate hydrogel microspheres, the appearance of which is as follows figure 2 As shown in (A), the particle size of the calcium alginate hydrogel microspheres is 3-5 mm.

[0040] Preparation of nano-silver / diatomaceous earth / calcium alginate composite antibacterial hydrogel microspheres:

[0041] (1) Purification of natural diatomite: Grind and sieve natural diatomite, take 10g of the powder and add it to hydrochloric acid solution (2mol / L, 500ml) to remove organic and inorganic impurities, then use a magnetic stirrer to continuously stir for 8 hours, and filter through a 200-mesh sieve After nettin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com