Organic metal framework material mixed matrix membrane and preparation method thereof

A technology of mixed matrix membranes and skeleton materials, applied in the field of membrane materials, to achieve low cost, various specifications, and reduce the loss of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

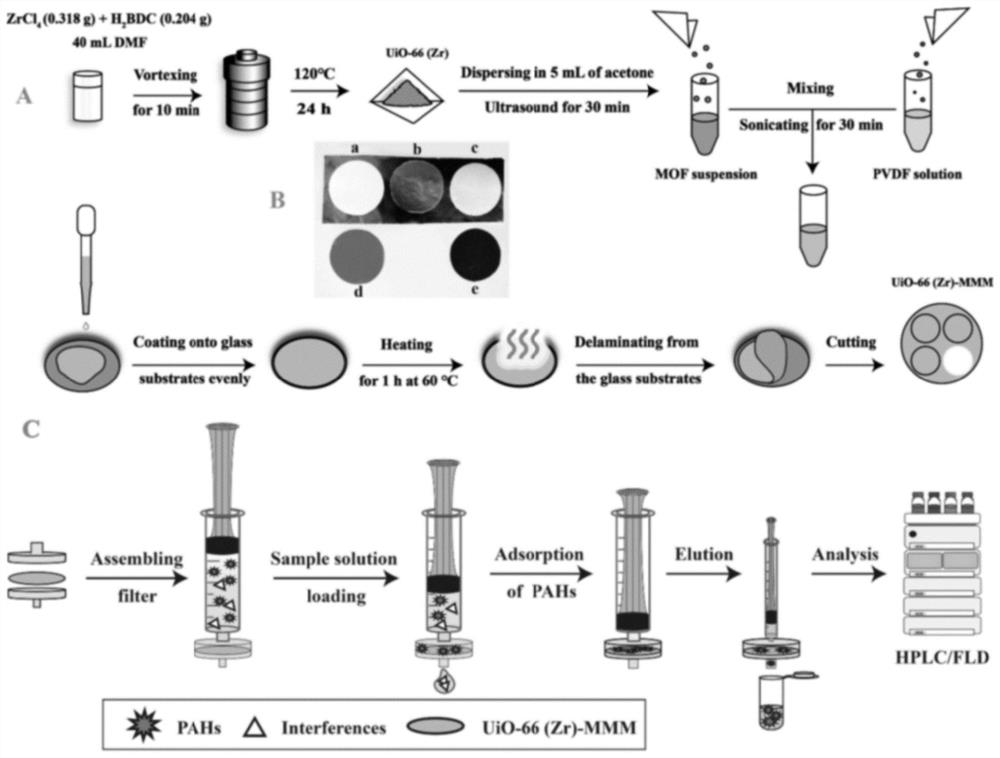

[0034] The preparation method of the UiO-66(Zr)-MMMs mixed matrix membrane of the present embodiment adopts the following steps:

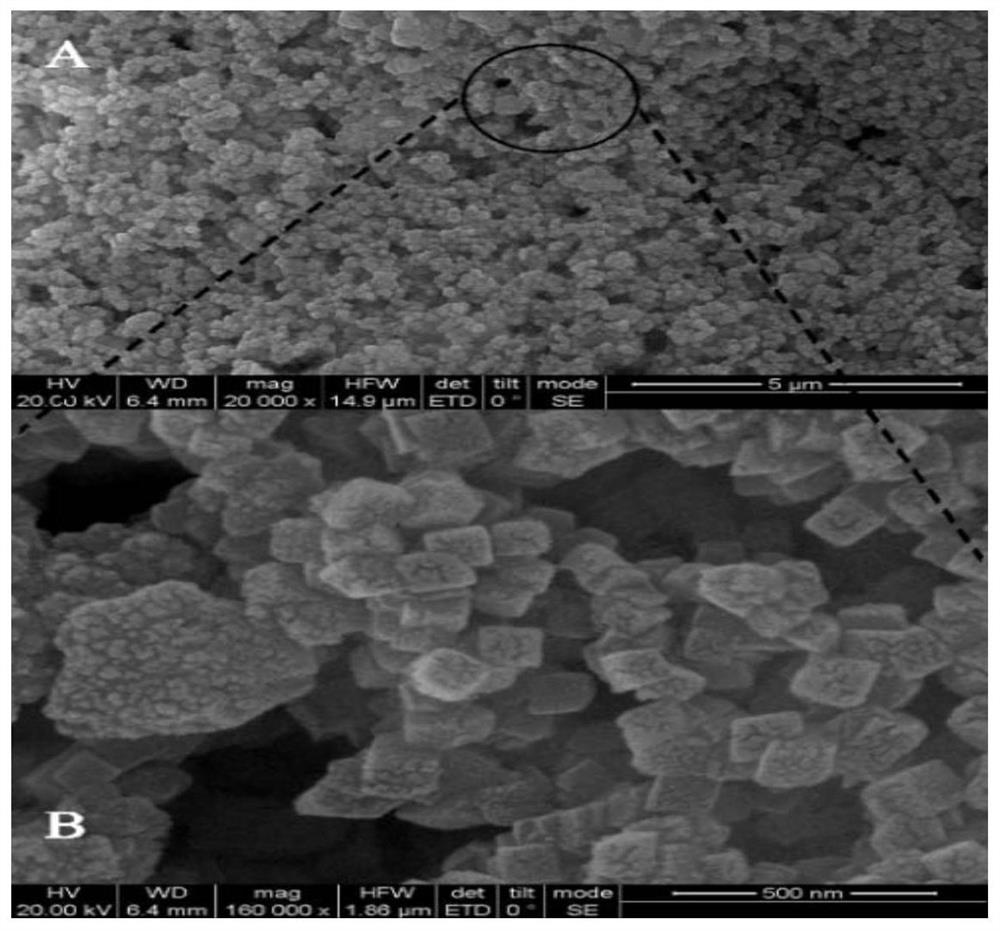

[0035] 1) UiO-66(Zr): Mix zirconium chloride (0.318g) and terephthalic acid (0.204g) with 40mL DMF, stir it magnetically for 10min, then put it in an autoclave and react at 120°C 24h. After cooling, the mixture was soaked in 50 mL DMF for 30 min, centrifuged at 8000 rpm for 5 min to collect the solid product, washed three times with ultrapure water and ethanol, and then vacuum-dried at 60 °C for 10 h to obtain a white powder. This embodiment should have the following features: the X-ray diffraction results show the characteristic peaks of UiO-66(Zr) near the positions of θ=7.3°, 8.4°, 25.7°, etc., and UiO-66(Zr) is formed into a film , still retains a certain crystal structure; Fourier transform infrared spectrum at 1568, 1020, 742, 665 and 1180cm -1 There are characteristic absorption peaks nearby.

Embodiment 2

[0037] The MIL-53(Al)-MMMs mixed matrix membrane preparation method of this embodiment adopts the following steps:

[0038]1) MIL-53(Al): Disperse 3.38g of aluminum nitrate nonahydrate and 1.00g of terephthalic acid in a mixed solution of 44mL DMF and 16mL of ultrapure water, and mechanically stir in a water bath at 40°C for 2h . The mixture was transferred to an autoclave with a volume of 100 mL, and then reacted in an oven at 130° C. for 48 h. After cooling, the mixture was soaked in 50 mL of DMF for 30 min, centrifuged at 8000 rpm for 5 min to collect the solid product, washed three times with ultrapure water and ethanol, and then vacuum-dried at 60°C for 10 h to obtain a white powder.

Embodiment 3

[0040] NH in this example 2 -MIL-101 (Fe)-MMMs mixed matrix film preparation method, adopts the following steps:

[0041] 1) NH 2 -MIL-101(Fe): Preparation of NH using solvothermal method 2 -MIL-101(Fe). Ferric chloride hexahydrate (19.75 mmol, 5.338 g) and terephthalic acid (10.0 mmol, 1.812 g) were added to 60 mL of DMF solution, and the mixture was magnetically stirred for 10 min, and then transferred to a 100 mL polytetrafluoroethylene liner in a stainless steel autoclave and heated at 110°C for 24h. After cooling, the mixture was soaked in 50 mL of DMF for 30 min, centrifuged at 8000 rpm for 5 min to collect the solid product, washed three times with ultrapure water and ethanol, and then vacuum-dried at 60 °C for 10 h to obtain a dark brown solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com