Weak acid cation resin for extracting vitamin B12 and synthesis method thereof

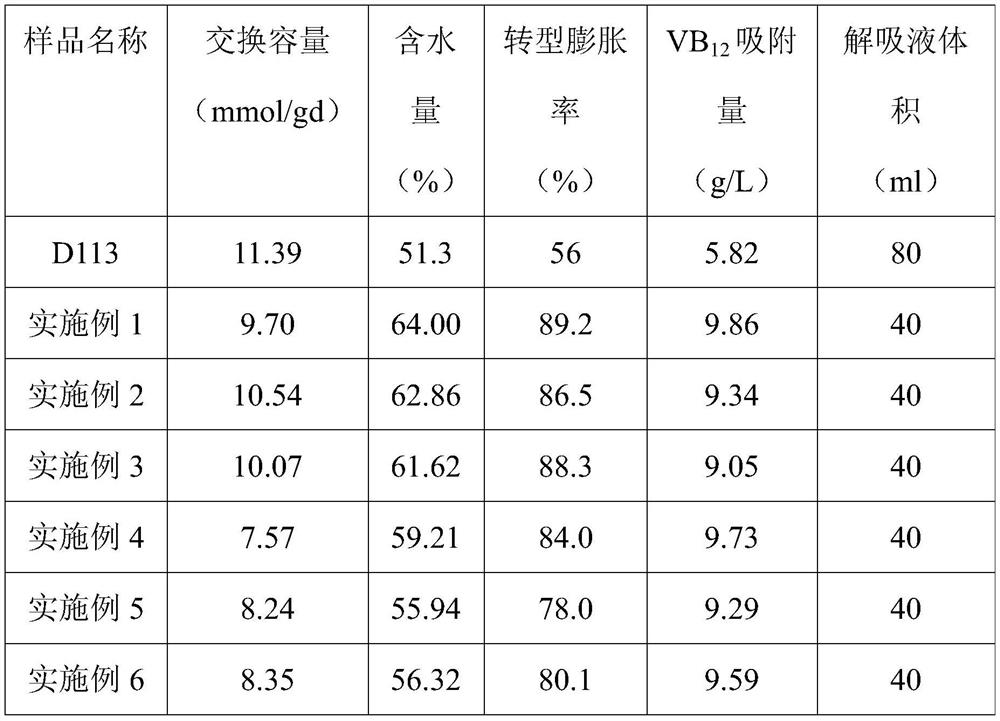

A cation resin, B12 technology, applied in the fields of medicine and chemical industry, can solve the problems of inability to guarantee the removal of specific impurities, incomplete elution, small adsorption capacity, etc., achieve good mechanical strength and anti-oxidation performance, low resin transformation expansion rate, The effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of weak acid cation resin for extracting vitamin B12 of the present invention and synthetic method thereof, comprises the following steps:

[0034] S1. Add the dispersant and the aqueous phase inhibitor to the saline, the mass volume ratio of the dispersant: the aqueous phase inhibitor: the saline = 0.05~0.50: 0.0005~0.0010: 100, and the density of the saline is d=1.15~ 1.18g / ml (NaCl content = 20% ~ 24%), heat up and stir to make a water phase; mix the monomer, porogen and initiator evenly to make an oil phase; add the oil phase to the water phase and let it stand After 15 minutes, after the oil phase and the water phase are completely separated, control the stirring speed to adjust the particle size of the oil phase, and then carry out segmental heat preservation operation to complete the polymerization reaction; after the reaction, extract and recover the porogen by water vapor, wash with water, and dry. Sieve to obtain the weak acid cation resin precursor-whi...

Embodiment 1

[0048] In a 3000ml three-necked bottle, add 1200ml of salt water (d=1.18g / ml), 60g of 5% hydroxyethyl cellulose solution, 12ml of 0.1% methylene blue aqueous solution, stir well, and heat up to 40°C for later use . Add 191.1g of methyl methacrylate, 127.5g of methyl acrylate, 34.2g of 63.0% divinylbenzene, 7.2g of TAIC, 7.2g of benzoyl peroxide, and 216g of 200# gasoline into a 1000ml beaker. After stirring evenly, add In the three-neck bottle, let it stand for 10 minutes. After the oil-water phase layering is stable, start stirring to beat the particle size, and control the particle size range to 0.38mm. Raise the temperature to 65°C at a rate of 2°C / 10 minutes, keep the temperature for 3 hours, raise the temperature to 75°C, keep the temperature for 3 hours, raise the temperature to 95°C, and keep the temperature for 6 hours. Cool down and wash the balls. Put the white balls into the water vapor extractor, pass through the water vapor at 105°C, blow off and recover the por...

Embodiment 2

[0052] In a 3000ml three-necked bottle, add 1200ml of salt water (d=1.15g / ml), 60g of 5% hydroxyethyl cellulose solution, 12ml of 0.1% methylene blue aqueous solution, stir well, and heat up to 40°C for later use . Add 16.2g of methyl methacrylate, 307.1g of methyl acrylate, 45.7g of 63.0% divinylbenzene, 7.2g of TAIC, 7.2g of benzoyl peroxide, 126g of 200# gasoline, and 72g of toluene into a 1000ml beaker, and stir well Finally, add it to the three-necked bottle and let it stand for 10 minutes. After the oil-water phase is separated and stabilized, start stirring to beat the particle size, and control the particle size range to 0.4mm. Raise the temperature to 65°C at a rate of 2°C / 10 minutes, keep the temperature for 3 hours, raise the temperature to 85°C, keep the temperature for 3 hours, raise the temperature to 95°C, and keep the temperature for 6 hours. Cool down and wash the balls. Put the white balls into the water vapor extractor, pass through the water vapor at 106°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com