High-temperature-resistant alkali-activated aluminosilicate binder and preparation method thereof

A technology of aluminosilicate and binder, which is applied in the field of refractory material manufacturing, can solve the problems of uneven particle size distribution, high clay content, low bonding strength, etc., and achieve small changes in linear shrinkage, prolong service life, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

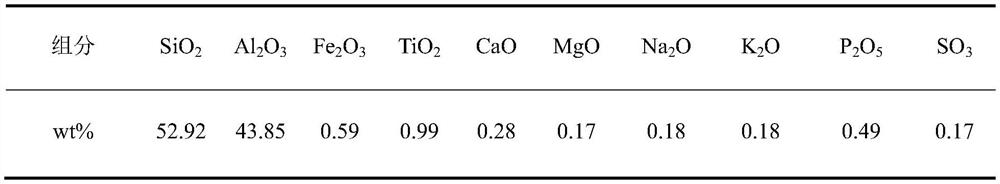

[0037] A method for preparing a high-temperature-resistant alkali-activated aluminosilicate binder of the present invention comprises the following steps,

[0038] Step 1, according to the component preparation raw material of described binder, the metakaolin that weighs, silica fume and water glass, KOH, distilled water are mixed, and water glass, KOH, distilled water are used as alkali activator, so water glass and distilled water The formed system water has a mass ratio of metakaolin and silica fume of 0.5, and is mixed and stirred to obtain an aluminosilicate polymer slurry;

[0039] Step 2, then add white corundum powder, so that the solid content of the aluminosilicate polymer slurry, that is, the mass ratio of metakaolin and silica fume to white corundum powder is 1:1, and stir evenly to obtain a mixed slurry, that is, high temperature resistant Alkali activated aluminosilicate binder;

[0040] Step 3: pour the mixed slurry into a triple steel mold of 40mm×40mm×160mm, ...

Embodiment 1

[0043] Put 35 parts of metakaolin with a particle size of 1.5 μm and 7 parts of silica fume with a size of 200 nm into a stirring pot and stir evenly, then mix 5 parts of KOH, 50 parts of water glass and 10 parts of distilled water to obtain the aluminosilicate polymer Pour the slurry into a stirring pot and continue stirring with 50 parts of white corundum micropowder for 5 minutes. The obtained binder is relatively thin, and the compressive strength after curing at 90°C is 50MPa, and the flexural strength is 5.8MPa;

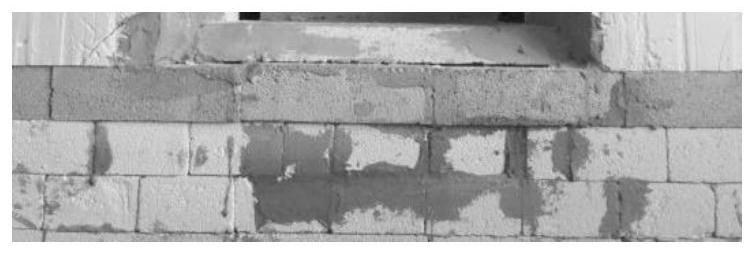

[0044] The bonding strength after high temperature heat treatment (850°C) is 0.95MPa, which can be used for refractory brick seam repair. Generally, the mortar seam is 0.2-0.5mm, which can solve the fine grinding of refractory bricks on the brick grinding machine, which saves labor and at the same time It can guarantee the quality and speed up the construction progress. Specific as figure 1 shown.

Embodiment 2

[0046] Put 35 parts of metakaolin with a particle size of 1.5 μm and 7 parts of silica fume with a size of 200 nm into a stirring pot and stir evenly, then mix 5 parts of KOH, 50 parts of water glass and 10 parts of distilled water to obtain the aluminosilicate polymer The slurry was poured into a stirring pot and stirred with 65 parts of white corundum micropowder for 3 minutes. The obtained binder was relatively thick, and the compressive strength after curing at 90°C was 70MPa, and the flexural strength was 8MPa.

[0047] After heat treatment at 850°C, the bonding strength of the adhesive is 1.3MPa, the flexural strength is 13MPa, the compressive strength is 91MPa, and the linear shrinkage rate is 0.25%. It can be used for repairing high-temperature-resistant materials on the outer layer of different types of high-temperature furnaces. .

[0048] After heat treatment at 1100°C, the bonding strength of the adhesive is 1.5MPa, the compressive strength is 84MPa, the flexural s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com