A kind of synthesis method and application of single crystal porous square flaky tungsten nitride nanoparticles

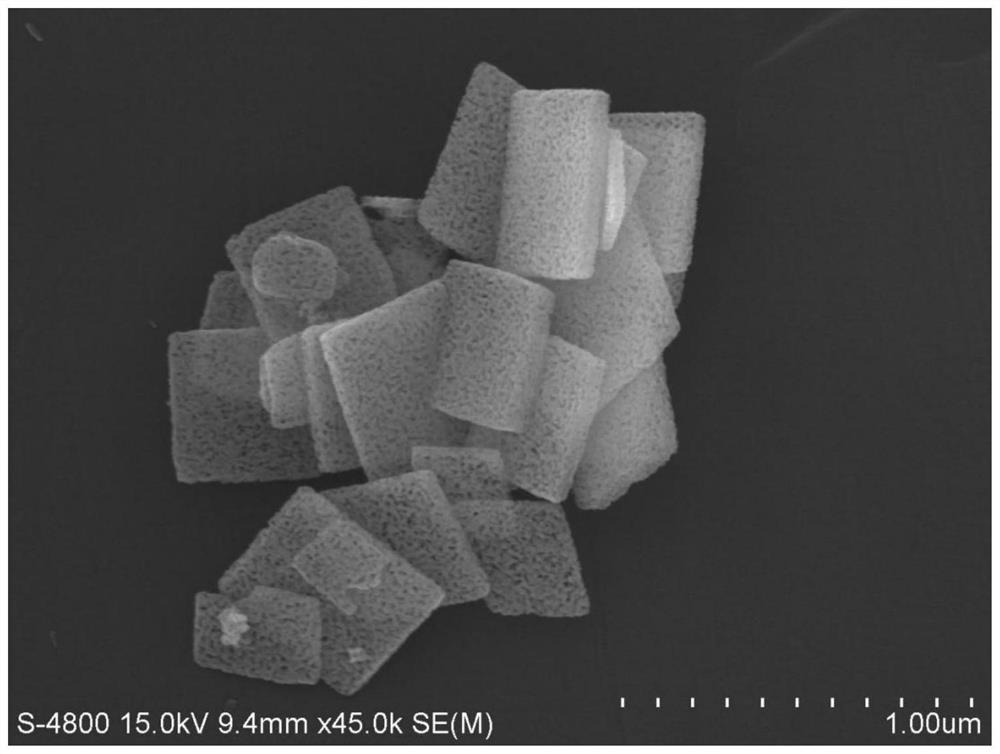

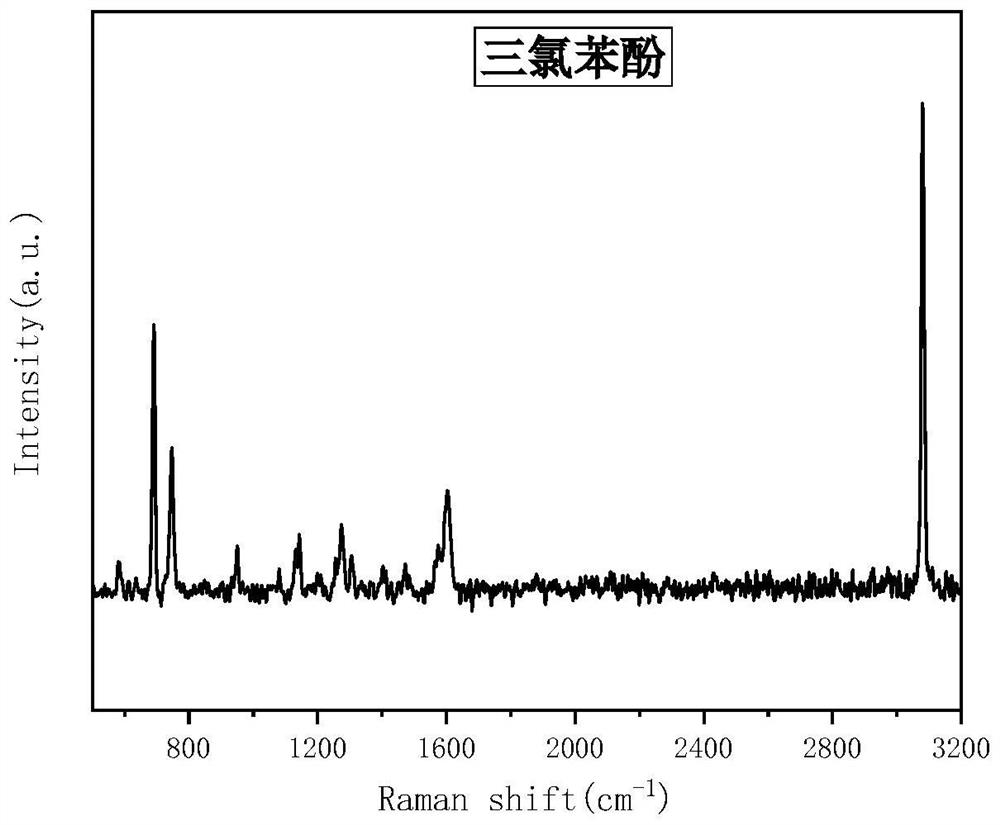

A tungsten nitride nanotechnology and synthesis method, which is applied in chemical instruments and methods, single crystal growth, nanotechnology, etc., can solve the problems of irregular material shape and lengthy steps, and achieve regular shape, good repeatability and Stability, effects of strong localized surface plasmon resonance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

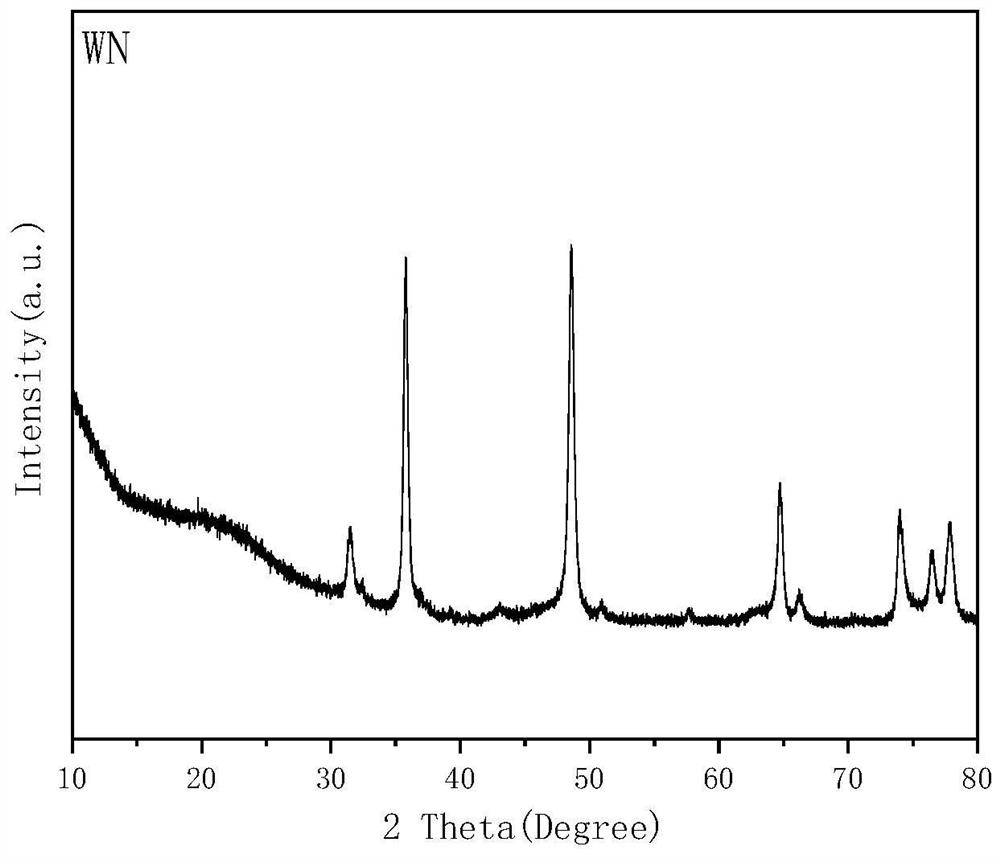

[0046] This embodiment provides a preparation method of single crystal porous square flaky tungsten nitride nanoparticles:

[0047] 1) Add 0.3g of sodium tungstate dihydrate and 0.1g of sodium oxalate into 25mL of deionized water, stir magnetically at a speed of 300r / min for 1.5h, add 1mL of a saturated aqueous solution of hydrochloric acid dropwise, continue stirring for 5min, turn to Put it into a 100mL reactor and keep it in a blast drying oven at 100°C for 12h. After cooling down to room temperature, transfer to a centrifuge tube, centrifuge (centrifugation speed 8000r / min, centrifugation time 7min), wash with deionized water, repeat 3 times, and keep the sample in a blast drying oven at 50°C for 12h to dry.

[0048] 2) Place the dried sample in a tube furnace, feed a mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 10mL / min, and the flow rate of nitrogen gas is 10mL / min), and the temperature is raised to 750°C and keep for 7h to get the final sample.

...

Embodiment 2

[0051] This embodiment provides a preparation method of single crystal porous square flaky tungsten nitride nanoparticles:

[0052] 1) Add 0.32g of sodium tungstate dihydrate and 0.12g of sodium oxalate into 27mL of deionized water, stir magnetically at a speed of 400r / min for 1h, add 1mL of a saturated aqueous solution of hydrochloric acid dropwise, continue stirring for 6min, and transfer to In a 100mL reactor, keep it at 110°C for 10h in a blast drying oven. After cooling down to room temperature, transfer to a centrifuge tube, centrifuge (centrifugation speed 9000r / min, centrifugation time 5min), wash with deionized water, repeat 4 times, and keep the sample in a blast drying oven at 60°C for 10h to dry.

[0053] 2) Place the dried sample in a tube furnace, feed a mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 10mL / min, and the flow rate of nitrogen gas is 15mL / min), and the temperature is raised to 760°C and keep for 6h to get the final sample.

[0054...

Embodiment 3

[0056] This embodiment provides a preparation method of single crystal porous square flaky tungsten nitride nanoparticles:

[0057] 1) Add 0.35g of sodium tungstate dihydrate and 0.13g of sodium oxalate into 30mL of deionized water, stir magnetically at a speed of 500r / min for 0.5h, add 1mL of a saturated aqueous solution of hydrochloric acid dropwise, continue stirring for 8min, turn to Put it into a 100mL reaction kettle and keep it in a blast drying oven at 120°C for 8h. After cooling down to room temperature, transfer to a centrifuge tube, centrifuge (centrifugation speed 10000r / min, centrifugation time 3min), wash with deionized water, repeat 5 times, and keep the sample in a blast drying oven at 70°C for 8h to dry.

[0058] 2) Place the dried sample in a tube furnace, feed a mixed gas of nitrogen and ammonia (the flow rate of ammonia gas is 10mL / min, and the flow rate of nitrogen gas is 20mL / min), and the temperature is raised to 770°C and keep for 5h to obtain the fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com