Preparation method of flocculation decolorizing agent

A technology of decolorizing agent and flocculation, which is applied in the field of preparation of flocculation decolorizing agent, can solve problems such as unsightly, hindering plant photosynthesis, destroying aquatic biological ecosystem, etc., and achieves rapid separation, good magnetic response performance, and good magnetic separation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present disclosure provides a preparation method of a flocculation decolorizing agent, including the following steps:

[0033] Step 1, using solvothermal method to prepare magnetic Fe 3 o 4 Nanoparticles;

[0034] Step 2, using alliin and a silane coupling agent to obtain a modified silane coupling agent;

[0035] Step 3, using modified silane coupling agent to magnetic Fe 3 o 4 Nanoparticles modified to obtain modified magnetic Fe 3 o 4 Nanoparticles;

[0036] Step 4, using modified magnetic Fe 3 o 4 Nanoparticles and L-allylglycine are used to graft and copolymerize chitosan to obtain a flocculating decolorizing agent.

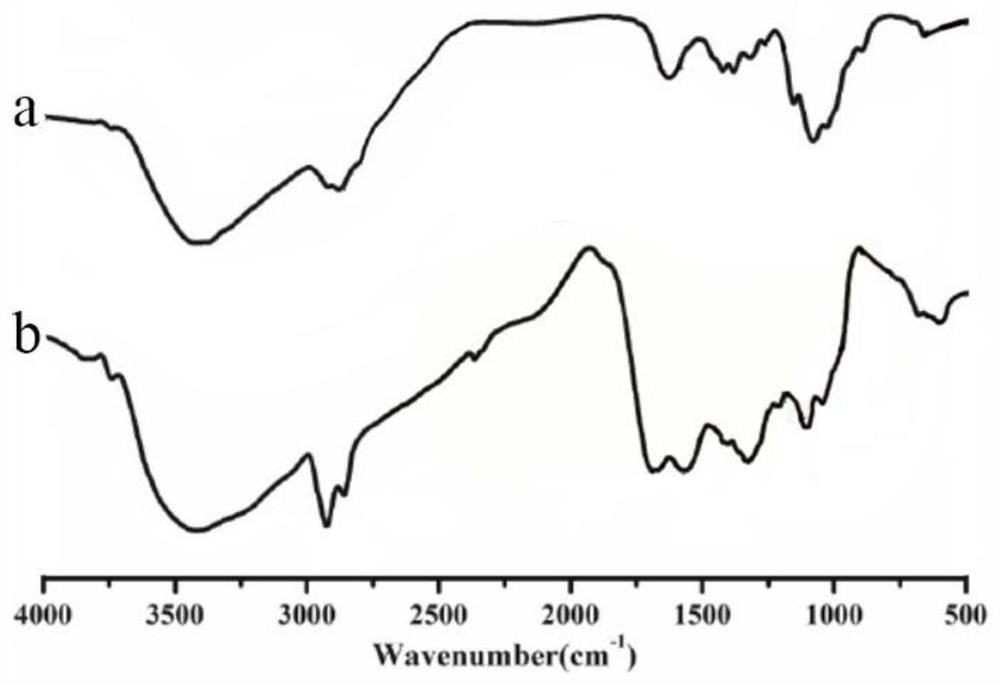

[0037] The preparation method of this embodiment uses chitosan as the main chain of grafting, and uses L-allylglycine, modified magnetic Fe 3 o 4 Nanoparticles are grafted comonomers, and a flocculating decolorizing agent is prepared. A large number of carboxyl, amino active groups and magnetic particles are introduced...

Embodiment 1

[0058] The preparation method of flocculating decolorizing agent comprises following steps:

[0059] Step 1, the FeCl 3 ·6H 2 O and sodium acetate were dissolved in ethylene glycol, polyethylene glycol was added and stirred vigorously until completely dissolved, then reacted at 200°C for 5 hours, cooled to room temperature, separated repeatedly with a magnet, washed 3 times with absolute ethanol, and dried to obtain Magnetic Fe 3 o 4 Nanoparticles; FeCl 3 ·6H 2 The consumption ratio of O, sodium acetate, ethylene glycol and polyethylene glycol is 1mmol: 3.2mmol: 8mL: 0.11mmol;

[0060] Step 2, add absolute ethanol to alliin and silane coupling agent KH560, react in an oil bath at 120°C under nitrogen protection for 6 hours, distill under reduced pressure, collect target fractions, and dry to obtain modified silane coupling agent; alliline The dosage ratio of acid, silane coupling agent KH560 and ethanol is 1.15mmol:1mmol:8mL;

[0061] Step 3, the magnetic Fe 3 o 4 Ult...

Embodiment 2

[0064] The preparation method of flocculating decolorizing agent comprises following steps:

[0065] Step 1, the FeCl 3 ·6H 2 Dissolve O and sodium acetate in ethylene glycol, add polyethylene glycol and stir vigorously until completely dissolved, then react at 220°C for 3 hours, cool to room temperature, separate repeatedly with a magnet, wash twice with absolute ethanol, and dry to obtain Magnetic Fe 3 o 4 Nanoparticles; FeCl 3 ·6H 2 The consumption ratio of O, sodium acetate, ethylene glycol and polyethylene glycol is 1mmol: 3.5mmol: 10mL: 0.12mmol;

[0066] Step 2, add absolute ethanol to alliin and silane coupling agent KH560, react in an oil bath at 110°C under nitrogen protection for 5 hours, distill under reduced pressure, collect target fractions, and dry to obtain modified silane coupling agent; The dosage ratio of acid, silane coupling agent KH560 and ethanol is 1.4mmol:1mmol:10mL;

[0067] Step 3, the magnetic Fe 3 o 4 Ultrasonic dispersion of nanoparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

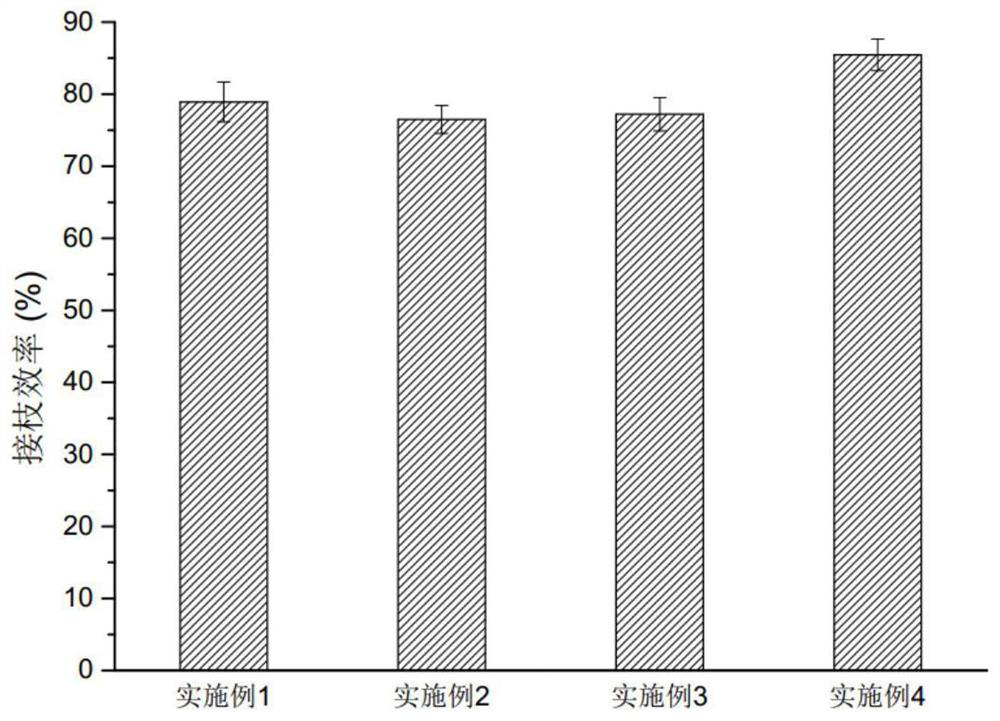

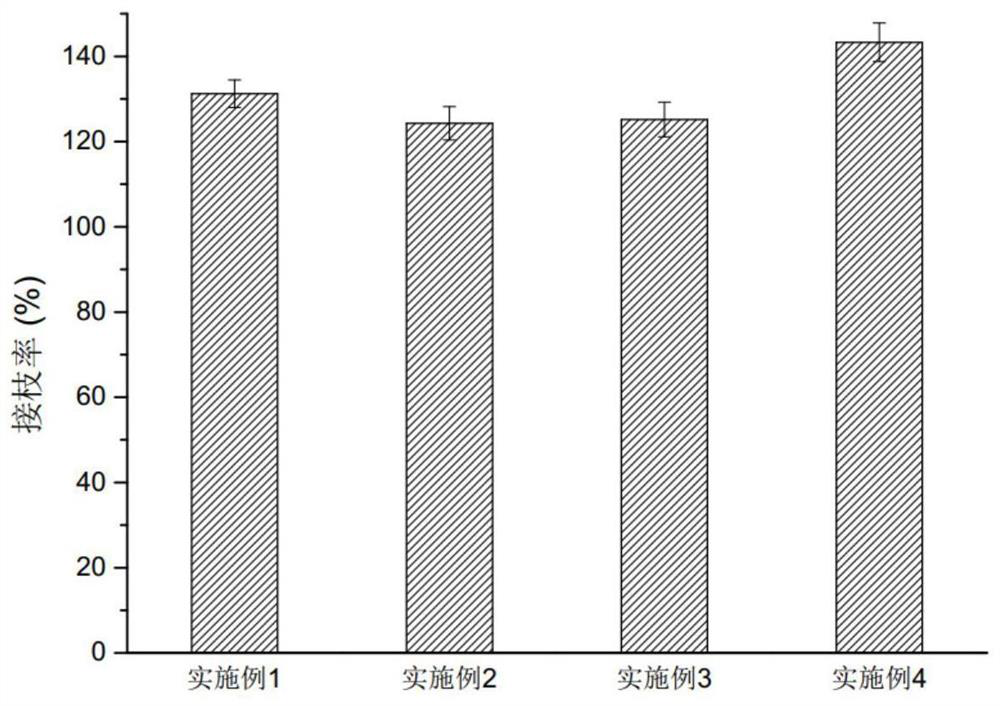

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com