Preparation method of silazane containing thioester bond

A nitrogen silane and ester bond technology, applied in the field of organosilicon fine chemicals synthesis, can solve the problems of large rubber porosity and high VOC, and achieve the effects of improving vulcanization performance, good product wear resistance and low rubber porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

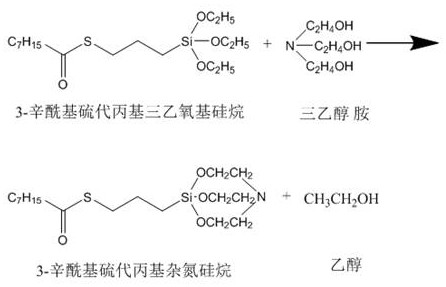

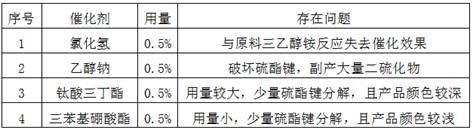

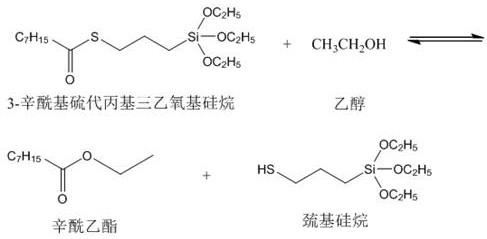

Method used

Image

Examples

Embodiment 1

[0035] Under nitrogen protection conditions, 364 g of 3-octyl thiopropyltriethoxysilane was added to the reaction vessel with mechanically stirred, and 200 g of DMF was added as a solvent, and 400 g of oxylate was added as an inhibitor, 1 g of triphenzene was added. Base acid ester exchange reaction catalyst.

[0036] The temperature was raised to 105 ° C, and 150 g of tsolamine was slowly added dropwise, and the ester exchange reaction was carried out, and the reaction temperature was controlled between 105-110 ° C. As the reaction initiated, the ethanol produced by the ester exchange was constantly vaporized to depart the reaction system, and then condensed with the brine condenser. After 4 hours of reaction, the system no longer produces ethanol, stop heating, and the ethanol 135 g is recovered. The reaction keena was reduced to 50-60 ° C for subsequent operation.

[0037] The mechanical stirring was opened and 1500 g of petroleum ether was added to the reaction kettle. As the ...

Embodiment 2

[0041] Under nitrogen protection conditions, 728 g of 3-octyl thiopropyltriethoxysilane was added to a mechanically stirred reaction kettle, and 440 g of DMF was added as a solvent, 826 g of oxylate as an inhibitor, and 2 g triphenzene was added. Base acid ester exchange reaction catalyst.

[0042] The temperature was raised to 105 ° C, and 300 g of triethoxide was slowly added dropwise, and the ester exchange reaction was carried out, and the reaction temperature was controlled between 105-110 ° C. As the reaction initiated, the ethanol produced by the ester exchange was constantly vaporized to depart the reaction system, and then condensed with the brine condenser. After the reaction was carried out for 4 h, the system no longer produced ethanol, stop heating, and the ethanol was recovered 270 g. The reaction keena was reduced to 50-60 ° C for subsequent operation.

[0043] The mechanical stirring was opened, and 3000 g of petroleum ether was added to the reactor. As the petrole...

Embodiment 3

[0047] Under nitrogen protection conditions, 1456 g of 3-octyl thiopropyltriethoxysilane was added to the reaction vessel with mechanically stirred, and 800 g of DMF was added as a solvent, and 1600 g of n-optate was added as an inhibitor, 5 g of triphenzene was added. Base acid ester exchange reaction catalyst.

[0048] The temperature was heated to 105 ° C, slowly added 600 g of triethylamine, and the ester exchange reaction was carried out, and the reaction temperature was controlled between 105-100 ° C. As the reaction initiated, the ethanol produced by the ester exchange was constantly vaporized to depart the reaction system, and then condensed with the brine condenser. After 4 hours of reaction, the system no longer produces ethanol, stop heating, and the ethanol 135 g is recovered. The reaction keena was reduced to 50-60 ° C for subsequent operation.

[0049] The mechanical stirring was opened, and 6000 g of petroleum ether was added to the reaction kettle to recrystallize....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com