Process for smelting vanadium titano-magnetite in blast furnace

A technology for vanadium titanomagnetite and blast furnace smelting, applied in the field of iron ore smelting, can solve problems such as resource waste and air pollution, and achieve the effects of increasing heat sources, realizing low carbon emissions and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

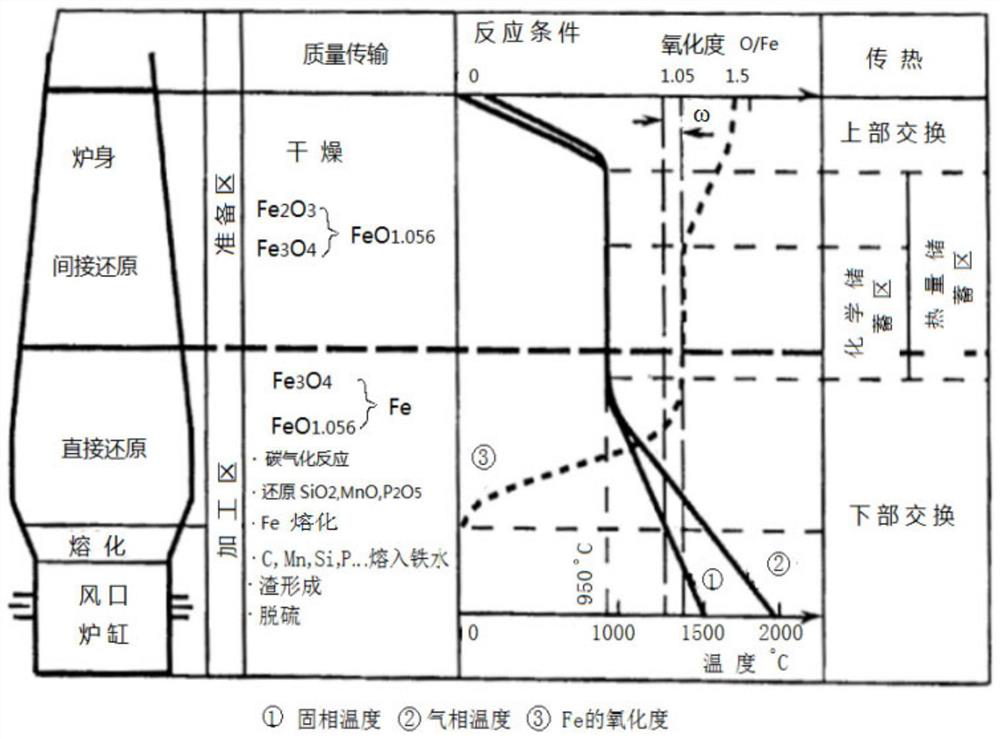

Image

Examples

Embodiment 1

[0038] (1). The hot air stove heats the air, and the output hot air composition: O 2 (g) is 21% (volume), CO 2 (g) 79%, temperature 1000°C, pressure 3Kg; flow rate is 1600m 3 / t.Fe, coal powder carrying capacity 150Kg / t.Fe;

[0039] (2). Hot air and pulverized coal are introduced into the tuyere of the blast furnace, in which oxygen O 2 (g) Participate in the charcoal combustion reaction as an oxidant, and the high temperature generated by the release of heat strengthens the endothermic reaction of charcoal gasification and promotes CO 2 (g) converted to double CO (g) to indirectly reduce iron oxide. On the whole, the coupling between the three reactions and the connection between the oxidizing agent and the reducing agent are smooth , speed up the process of chemical reactions;

[0040] (3). The blast furnace gas discharged from the top of the furnace, the content of CO (g) in the gas after dust removal is 30%, the temperature is 200°C, the pressure is 1Kg, and the rest ...

Embodiment 2

[0043] (1). Use CO instead of hot blast stove 2 (g) Exhaust gas replacement N 2 gas, from CO 2 (g) with O 2 Gas is combined to form a new type of hot air that is nitrogen-free, oxygen-rich, and carbon-rich; the hot air component is CO 2 (g) Content 55%, O 2 (g) The content is 45%, the temperature is 1000℃, the pressure is 3Kg, and the flow rate is 1600m 3 / t.Fe, coal powder carrying capacity 160Kg / t.Fe;

[0044] (2). Hot air and pulverized coal are introduced into the tuyeres of the blast furnace, and O in the hot air 2 (g) Combustion reaction with charcoal, the high temperature generated by the release of heat promotes CO 2 (g) The carbon gasification endothermic reaction occurs, which is converted into CO (g) to indirectly reduce iron oxide. The coupling effect between the three reactions accelerates the reduction reaction process, and the entire reduction smelting cycle can be shortened by more than 20%;

[0045] (3). Blast furnace gas rich in CO (g) is discharged fr...

Embodiment 3

[0048] ⑴Using CO in the hot blast stove 2 (g) Exhaust gas replaces N in the air 2 gas, from CO 2 (g) Exhaust gas and O 2Gas is combined to form a new type of hot air that is nitrogen-free, oxygen-rich, and carbon-rich; the hot air component is CO 2 (g) Content 65%, O 2 (g) content 35%, temperature 1100°C, pressure 2Kg, flow rate 1650m 3 / t.Fe pulverized coal carrying capacity 170 Kg / t.Fe;

[0049] ⑵The hot air and pulverized coal are introduced into the tuyeres of the blast furnace, and the O in the hot air 2 (g) Combustion with charcoal releases heat, and the resulting high temperature promotes CO 2 (g) The endothermic reaction of carbon gasification occurs, which is converted into CO (g) to indirectly reduce iron oxide. The coupling effect between the three reactions speeds up the reduction reaction process, and the entire reduction smelting can be shortened by more than 25%;

[0050] (3) Blast furnace gas rich in CO (g) is emitted from the top of the furnace, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com