Spinel type single-crystal cobalt-free high-voltage lithium nickel manganese oxide positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material, spinel-type technology, applied in the direction of polycrystalline material growth, positive electrode, secondary battery, etc., to achieve the effect of good capacity and rate performance, favorable for Li+ transport, and good rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a spinel-type single crystal cobalt-free high-voltage lithium nickel manganese oxide positive electrode material, comprising the following steps:

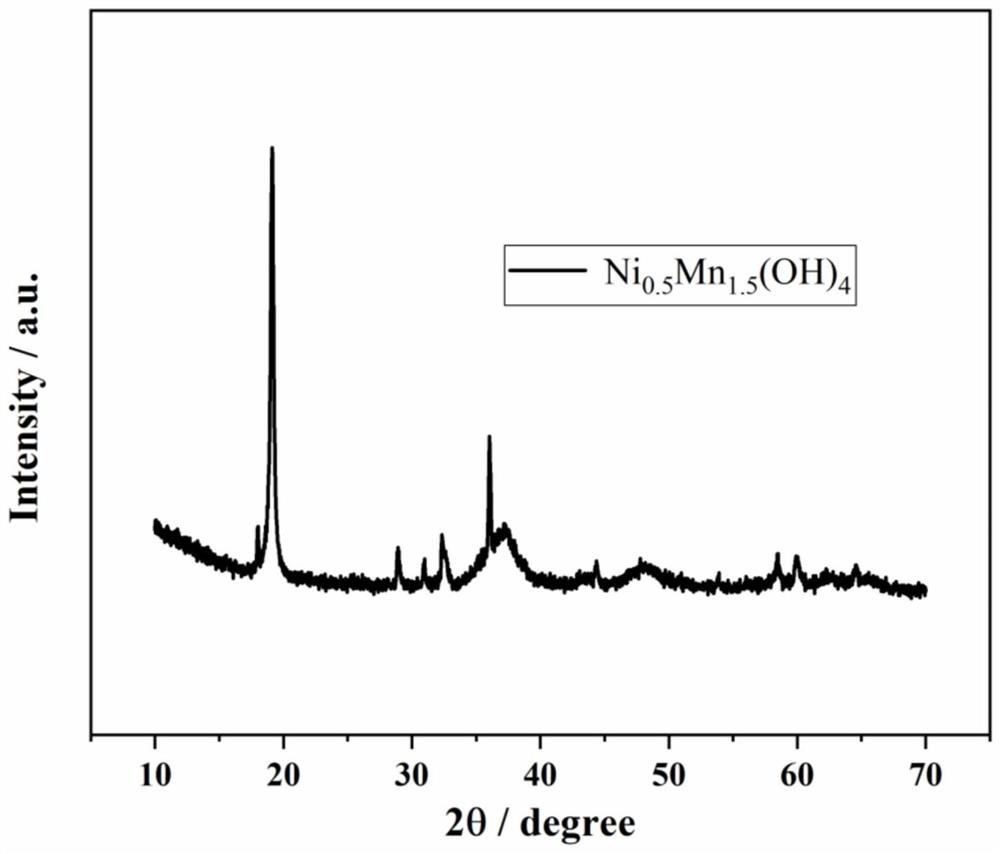

[0037] A) Under the action of precipitating agent, ammonia water and complexing agent, add nickel source and manganese source, carry out co-precipitation reaction, obtain Ni 0.5 mn 1.5 (OH) 4 binary precursor;

[0038] B) the Ni 0.5 mn 1.5 (OH) 4 The binary precursor is mixed with the lithium source, calcined at high temperature, then annealed at a low speed to keep it warm, and finally the temperature is naturally cooled to obtain single crystal LiNi 0.5 mn 1.5 o 4 Cathode material;

[0039] The temperature of the high-temperature calcination is 850-1000° C., the heating rate is 2-5° C. / min, and the time of high-temperature calcination is 6-15 hours.

[0040] In the present invention, under the action of precipitating agent, ammonia water and other complexing agents, a ...

Embodiment 1

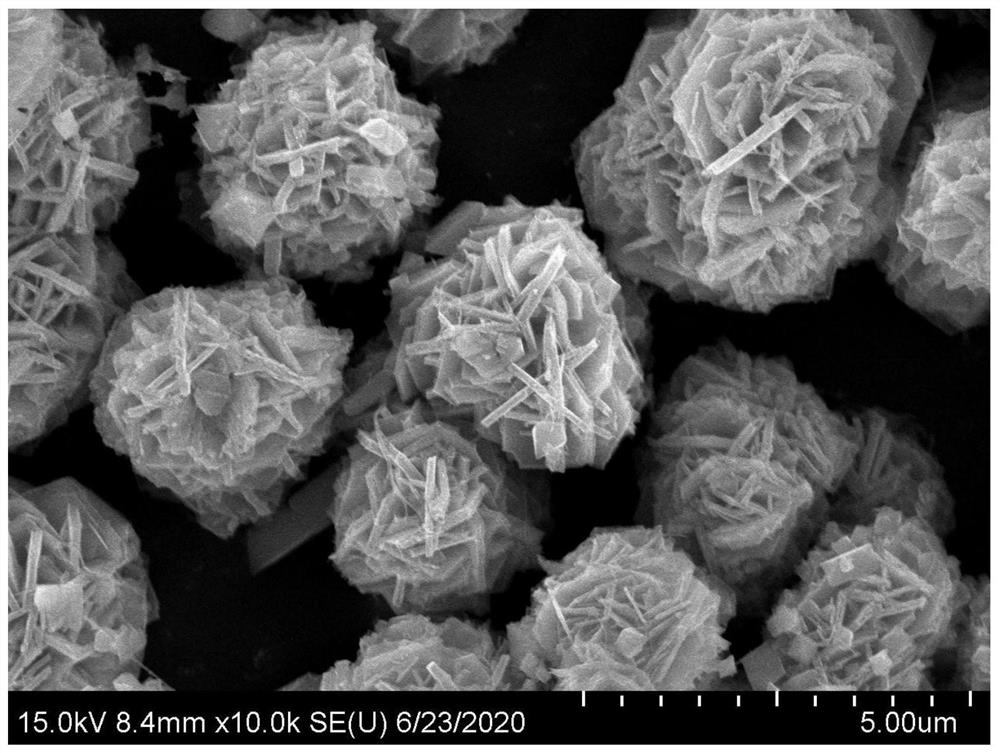

[0061] NiSO 4 ·6H 2 O and MnSO 4 ·H 2O Prepare a mixed solution with a metal ion concentration of 1.5 mol / L according to the molar ratio of Ni / Mn as 1 / 3, the initial pH is 4, and add 0.04 mol / L of ethylenediamine and 0.3 mol / L of ammonia as a complexing agent , add 4mol / L NaOH as a precipitant, control the pH to 11, and the reaction temperature to 55°C, control its sphericity by means of continuous feeding, keep reacting for 8 hours, and finally age the reaction product for 12 hours, filter, and centrifugally wash After drying, Ni with a particle size of 4 μm was obtained 0.5 mn 1.5 (OH) 4 Binary cobalt-free precursor.

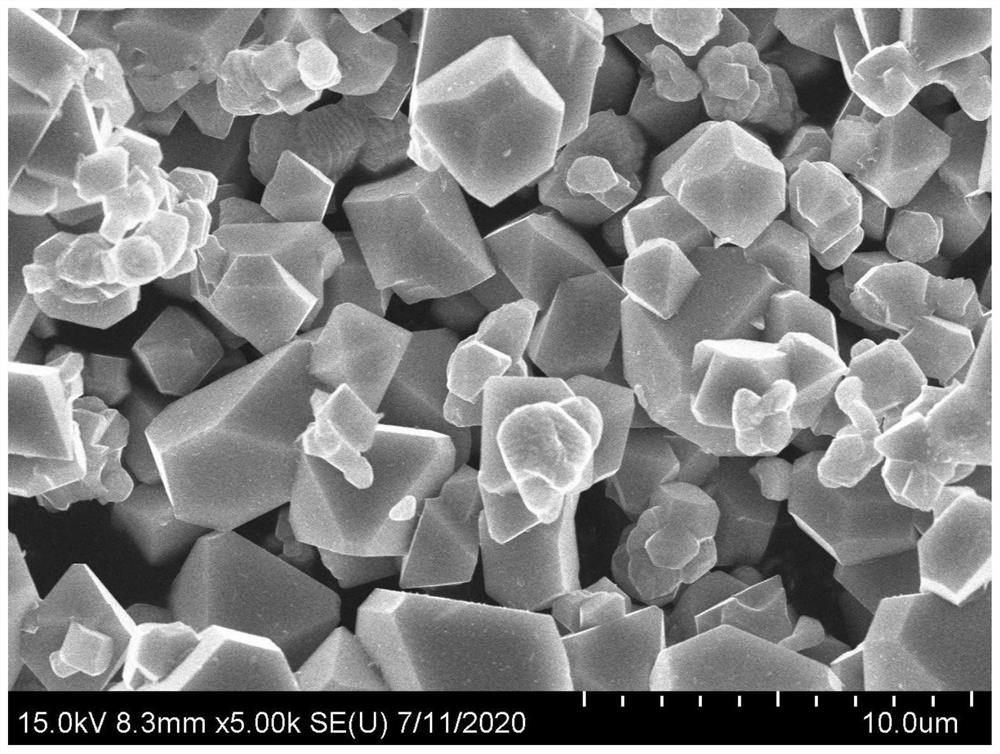

[0062] The above Ni 0.5 mn 1.5 (OH) 4 Precursors and Li 2 CO 3 Mix uniformly according to the molar ratio of 1:0.52, put it in a boat and place it in a muffle furnace for high-temperature calcination, during which air is properly blown in to control the atmosphere. From room temperature at a heating rate of 2°C / min, add heat to 980°C and keep the t...

Embodiment 2

[0070] Ni(Ac) 2 and Mn(Ac) 2 Prepare a mixed solution with a metal ion concentration of 1.5 mol / L according to the molar ratio of Ni / Mn as 1 / 3, the initial pH is 4.5, add 0.05 mol / L glycine and 0.3 mol / L ammonia water as a complexing agent, and add 2 mol / L of NaOH is used as a precipitating agent, the pH is controlled to be 11, and the reaction temperature is 55°C. Through continuous feeding, the sphericity is controlled, and the reaction is continued for 8 hours. Finally, the reaction product is aged for 12 hours, filtered, centrifuged, washed and dried. Ni with a particle size of 4 μm was obtained 0.5 mn 1.5 (OH) 4 Binary cobalt-free precursor.

[0071] The above Ni 0.5 mn 1.5 (OH) 4 Precursor and LiOH·H 2 O is uniformly mixed according to the molar ratio of 1:1.04, loaded into a boat and placed in a muffle furnace for high-temperature calcination, during which air is properly blown in to control the atmosphere. From room temperature at a heating rate of 2°C / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com