A hierarchical porous fe 3 the se 4 @nc@cnts Composite materials and their preparation methods and applications

A composite material, fe3se4 technology, applied in the direction of nanotechnology, active material electrode, nanotechnology, etc. for materials and surface science, can solve the problems of poor storage performance, low conductivity and large volume expansion, etc., to achieve uniform shape distribution, The effect of carrying less impurities and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

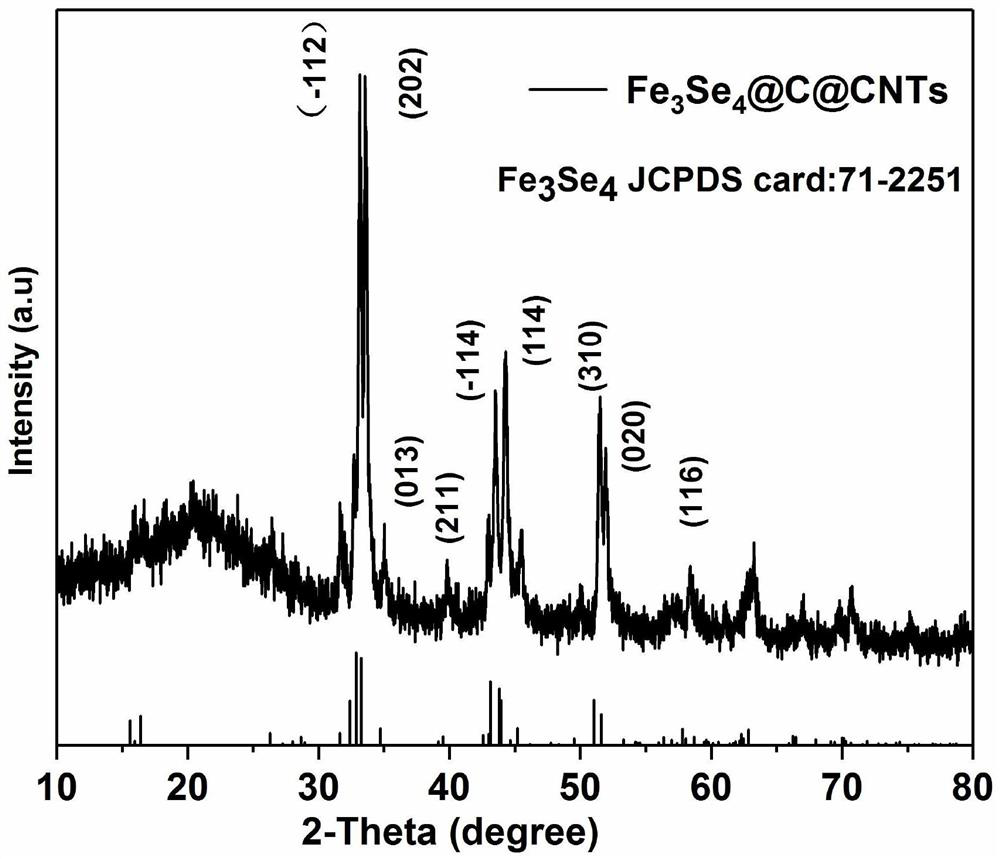

[0037] Put PVA(M w = 80000) was added to 100 mL of deionized water (the liquid-solid ratio was 12.5), and stirred at room temperature until it became clear to obtain a viscous solution A. 0.1g commercial CNTs, 10g Fe(NO 3 ) 3 , 10g NaCl nanoparticles were added to the viscous solution A, and the gel solution B was obtained by vigorous stirring. The obtained solution was then transferred to a freeze dryer and treated with freeze drying (cold trap temperature -96° C.) for 24 hours to obtain the precursor. After that, 1 g of the precursor and 2 g of selenium powder were selenized at 600 °C for 4 h under an argon protective atmosphere. Finally, the obtained sample was washed with water for several times and dried at 60 °C for 4 h to obtain hierarchical porous Fe. 3 Se 4 @C@CNTs composites. The obtained samples will be analyzed by Japanese Rigaku D / max-2500 X-ray diffraction analyzer, and the results are as follows figure 1 shown. All diffraction peaks of the final product c...

Embodiment 2

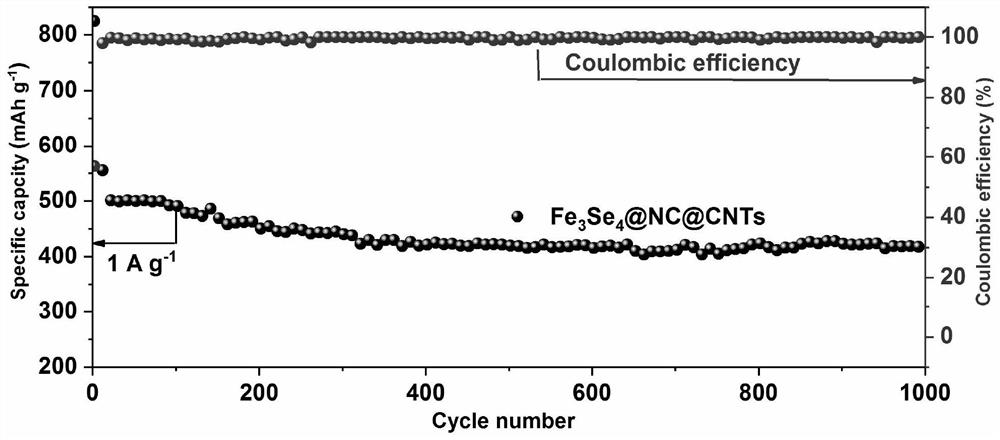

[0039] Put PVA(M w = 80000) was added to 100 mL of deionized water (the liquid-solid ratio was 12.5), and stirred at room temperature until it became clear to obtain a viscous solution A. 0.1g commercial CNTs, 10g Fe(NO 3 ) 3 , 5g CH 4 N 2 O, 10g NaCl nanoparticles were added to the viscous solution A, and the gel solution B was obtained by vigorous stirring. The obtained solution was then transferred to a freeze dryer and treated with freeze drying (cold trap temperature -96° C.) for 24 hours to obtain the precursor. Then, 1 g of the precursor and 2 g of selenium powder were selenized at 600 °C for 4 h under an argon protective atmosphere. Finally, the obtained sample was washed with water for several times and dried at 60 °C for 4 h to obtain hierarchical porous Fe. 3 Se 4 @NC@CNTs composites. The obtained samples will be analyzed by Japanese Rigaku D / max-2500 X-ray diffraction analyzer, and the results are as follows Figure 4 shown. All diffraction peaks of the fi...

Embodiment 3

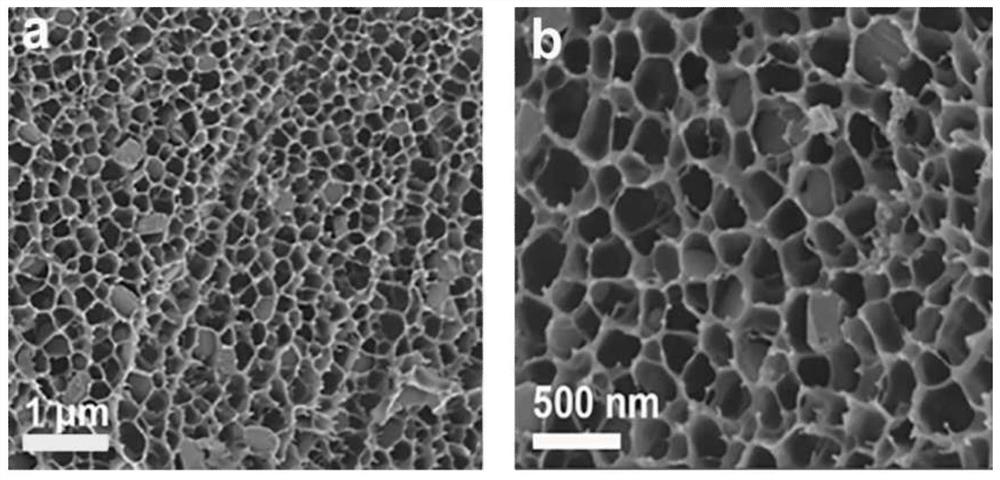

[0041] Put PVA(M w = 80000) was added to 100 mL of deionized water (the liquid-solid ratio was 12.5), and stirred at room temperature until it became clear to obtain a viscous solution A. 0.1 g commercial CNTs and 5 g Fe(NO 3 ) 3 , 5g CH 4 N 2 O, 10 g NaCl nanoparticles were added to the viscous solution A, and the suspension B was obtained by vigorous stirring. The obtained solution was transferred to a freeze dryer and treated with freeze drying (cold trap temperature -96° C.) for 24 hours to obtain the precursor. Finally, 1 g of the precursor and 2 g of selenium powder were selenized at 600 °C for 4 h under an argon protective atmosphere. Finally, the obtained sample was washed with water for many times and dried at 60 °C for 4 h to obtain hierarchical porous Fe. 3 Se 4 @NC@CNTs composites. Using transmission electron microscopy (TEM, JEOL-JEM-2100F) to observe the samples, it was found that the 3D conductive network of porous carbon and many CNTs were intertwined, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com