Hierarchical pore zeolite molecular sieve as well as preparation method and application thereof

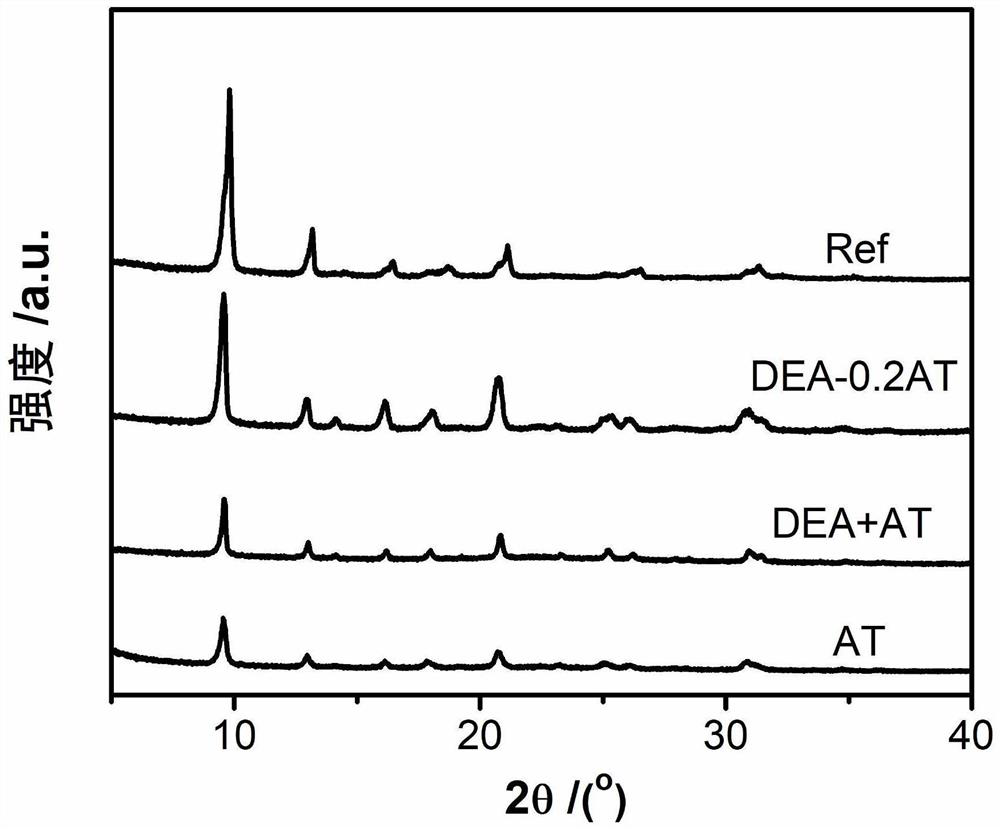

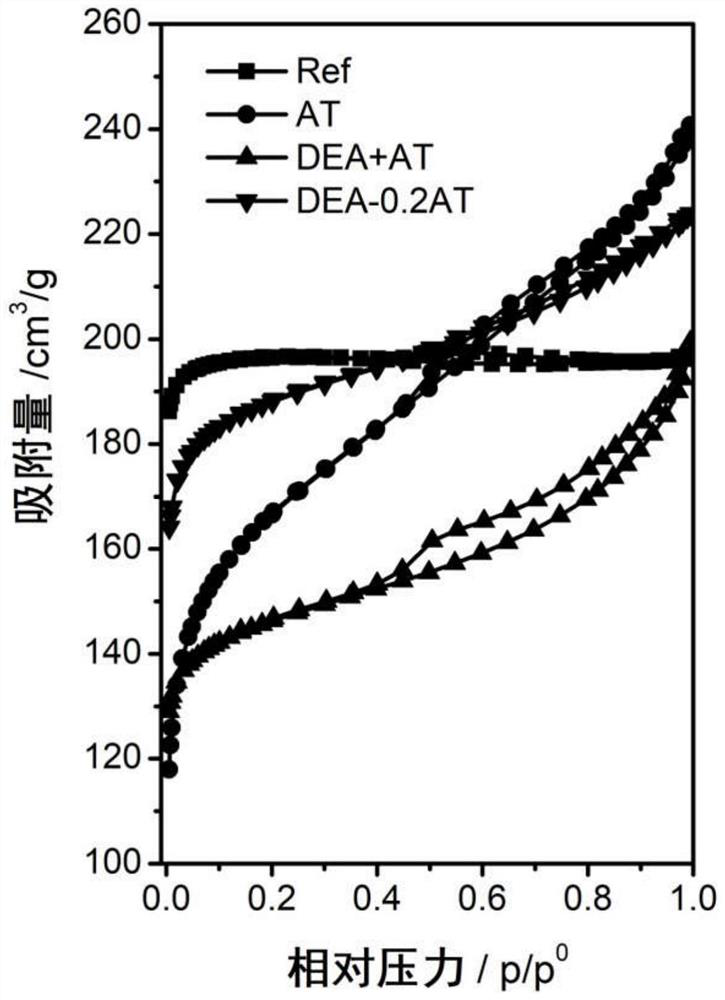

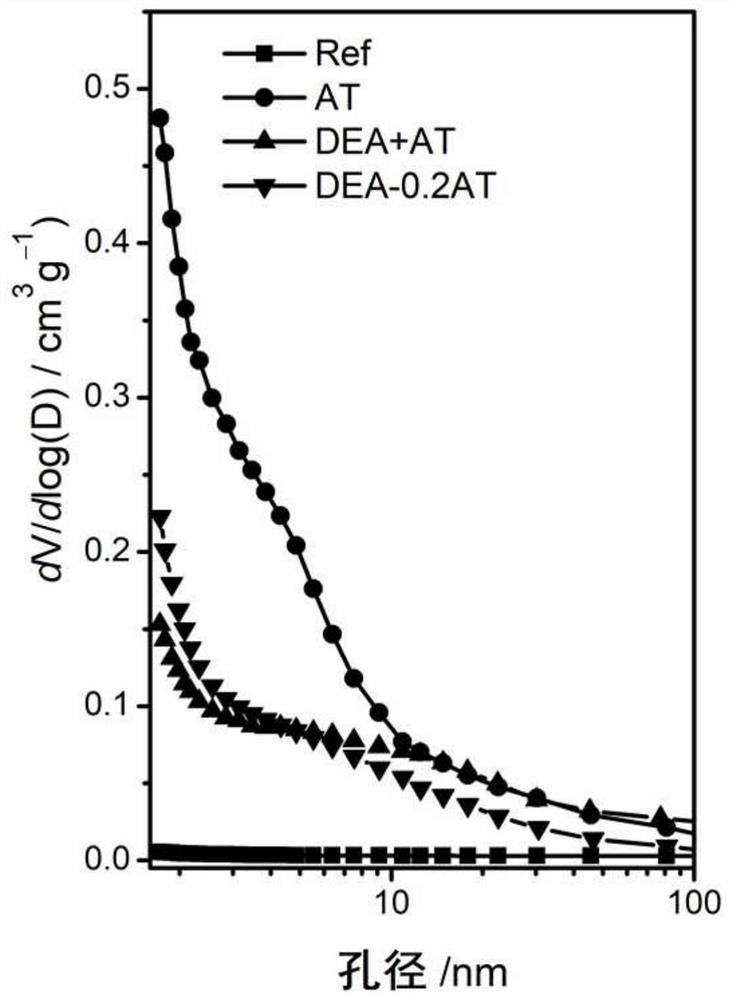

A zeolite molecular sieve and multi-stage pore technology, applied in the field of molecular sieves, can solve the problems of reduced MTO catalytic life, increased alkali treatment cost, zeolite framework collapse, etc., and achieves the effects of good framework preservation, high mesopore volume and complete morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a method for preparing a hydrogen-type hierarchically porous H-SSZ-13 zeolite molecular sieve, which includes the following steps:

[0068] (1) Roast SSZ-13 zeolite raw powder (Si / Al=23) at high temperature at 550°C for 10h, and the heating rate during the roasting process is 1°C / min to obtain Na-SSZ-13 zeolite raw powder, which is placed in Dehydration was completed in a vacuum oven at 160° C. for 4 hours.

[0069] (2) Weigh 3g of the dehydrated Na-SSZ-13 zeolite powder in the above step (1), place it in a closed container, then add a sufficient amount of diethylamine, stir for 1h, and make the Na-SSZ-13 zeolite powder fully The zeolite skeleton is protected by absorbing diethylamine; then the raw zeolite powder is separated by suction filtration, and the obtained solid sample is placed in a fume hood for a period of time to volatilize the diethylamine on the surface of the zeolite.

[0070] (3) Pour the Na-SSZ-13 zeolite raw powder obtained i...

Embodiment 2

[0074] This embodiment provides a method for preparing a hydrogen-type hierarchically porous H-SSZ-13 zeolite molecular sieve, which includes the following steps:

[0075] (1) Roast SSZ-13 zeolite raw powder (Si / Al=23) at high temperature at 550°C for 10h, and the heating rate during the roasting process is 1°C / min to obtain Na-SSZ-13 zeolite raw powder, which is placed in Dehydration was completed in a vacuum oven at 180° C. for 2 hours.

[0076] (2) Weigh 3g of the dehydrated Na-SSZ-13 zeolite powder in the above step (1), place it in a closed container, then add a sufficient amount of diethylamine, stir for 1h, and make the Na-SSZ-13 zeolite powder fully The zeolite skeleton is protected by absorbing diethylamine; then the raw zeolite powder is separated by suction filtration, and the obtained solid sample is placed in a fume hood for a period of time to volatilize the diethylamine on the surface of the zeolite.

[0077] (3) Pour the Na-SSZ-13 zeolite raw powder obtained i...

Embodiment 3

[0081] This embodiment provides a method for preparing a hydrogen-type hierarchically porous H-SSZ-13 zeolite molecular sieve, which includes the following steps:

[0082] (1) Roast SSZ-13 zeolite raw powder (Si / Al=23) at high temperature at 550°C for 10h, and the heating rate during the roasting process is 1°C / min to obtain Na-SSZ-13 zeolite raw powder, which is placed in Dehydration was completed in a vacuum oven at 180° C. for 2 hours.

[0083] (2) Weigh 3g of the dehydrated Na-SSZ-13 zeolite powder in the above step (1), place it in a closed container, then add a sufficient amount of diethylamine, stir for 1h, and make the Na-SSZ-13 zeolite powder fully The zeolite skeleton is protected by absorbing diethylamine; then the raw zeolite powder is separated by suction filtration, and the obtained solid sample is placed in a fume hood for a period of time to volatilize the diethylamine on the surface of the zeolite.

[0084](3) Pour the Na-SSZ-13 zeolite raw powder obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com