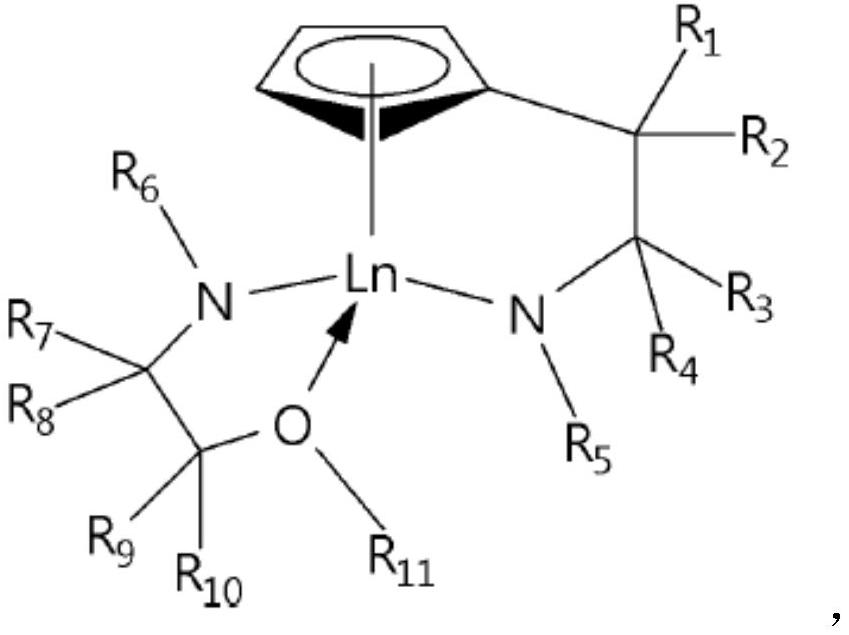

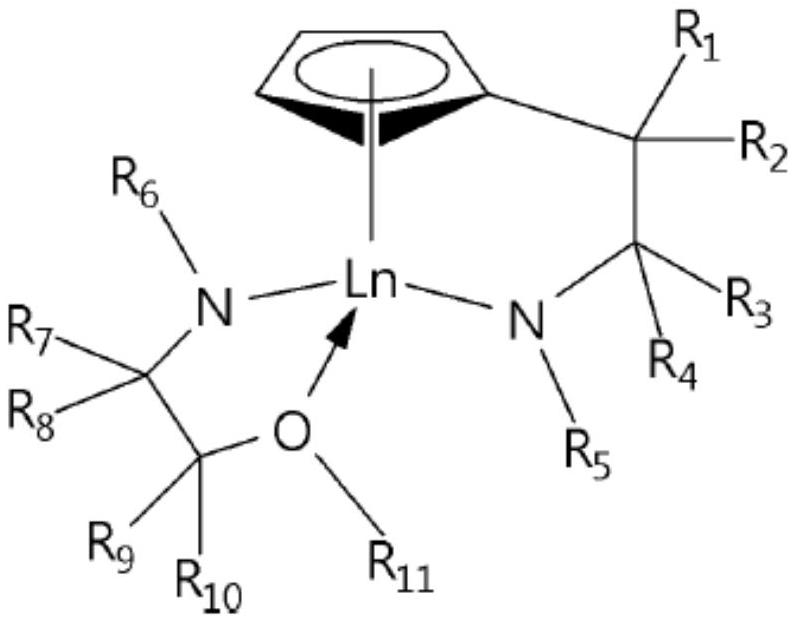

Rare earth precursor, manufacturing method therefor, and method for forming thin film by using same

A thin film, rare earth element technology, applied in the field of vapor deposition compounds, can solve the problems of thermal stability, low deposition rate, difficult to remove, etc., and achieve excellent film characteristics, uniform film deposition, and the effect of preventing side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

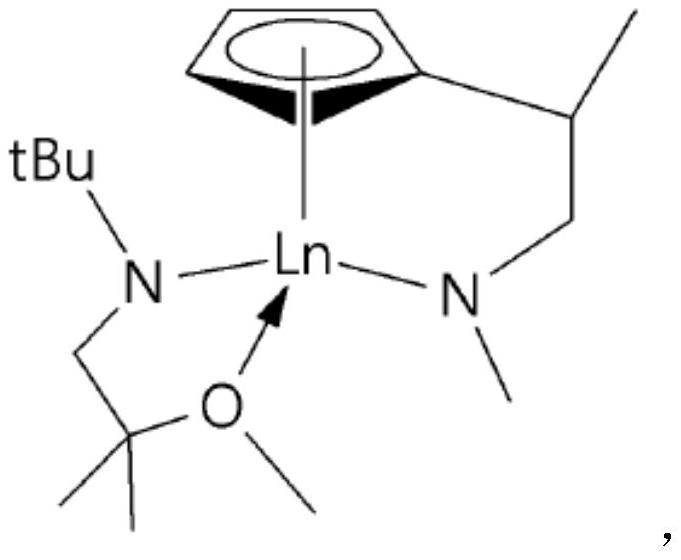

Embodiment 1

[0064] In order to carry out the chemical reaction represented by the following chemical formula 2, YCl 3 (1 eq.) was added to the flask and dissolved in organic solvent. Then, cyclopentadienyl (Cp) derivative ligand (1 equivalent) and triethylamine (TEA) (2 equivalents) were added thereto and stirred.

[0065] Then, a Li-substituted alkoxyamine-based ligand (1 equiv) was added to the mixture and stirred overnight.

[0066] After completion of the reaction, the resulting mixture was filtered under reduced pressure to remove the solvent and then purified by distillation or sublimation to obtain the final compound of pure yttrium (Y) vapor deposition precursor.

[0067] [Chemical Reaction Formula 2]

[0068]

Embodiment 2

[0070] Use LaCl 3 Instead of YCl in Example 1 3 The final compound of the lanthanum (La) vapor deposition precursor is obtained.

preparation Embodiment 1

[0072] By alternately applying the novel rare earth precursor synthesized in Example 1 of the present invention and the reactant O 3 , to deposit rare earth thin films on the substrate. The substrate used in this experiment was a p-type Si wafer, and its resistance was 0.02 Ω·cm. Prior to deposition, p-type Si wafers were cleaned by sonicating in each of acetone, ethanol and deionized water (DI water) for 10 minutes. The native oxide film formed on the Si wafer was immersed in 10% HF solution (HF:H 2 O=1:9) for 10 seconds and then removed. The substrate is kept ready by being held at a temperature of 150°C to 450°C. The novel solid rare earth precursor synthesized in Example 1 was evaporated in a bubbler maintained at a temperature of 90°C to 150°C.

[0073] Argon (Ar) is supplied as a purge gas to purge the remaining precursor and reaction gases in the deposition chamber. The flow rate of argon was set at 1000 sccm. The concentration is 224g / cm 3 Ozone (O 3 ) is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com