Pomegranate-shaped silicon oxide-nitrogen doped carbon composite material, synthesis method thereof and lithium ion capacitor

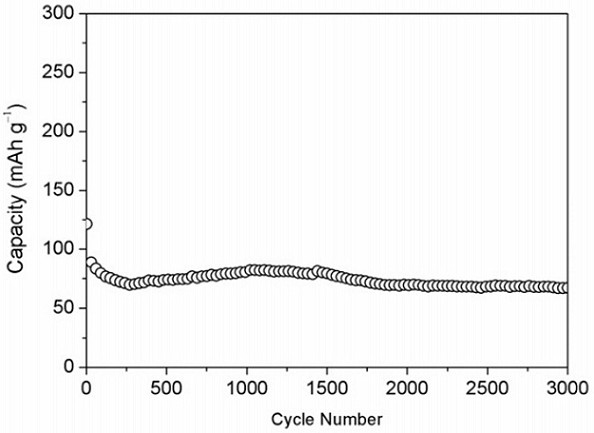

A nitrogen-doped carbon, composite material technology, applied in hybrid capacitors, hybrid capacitor electrodes, capacitors, etc., can solve the problems of loss of electron capacity, high cost, complex preparation process, etc., and achieve improved cycle performance, low cost, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

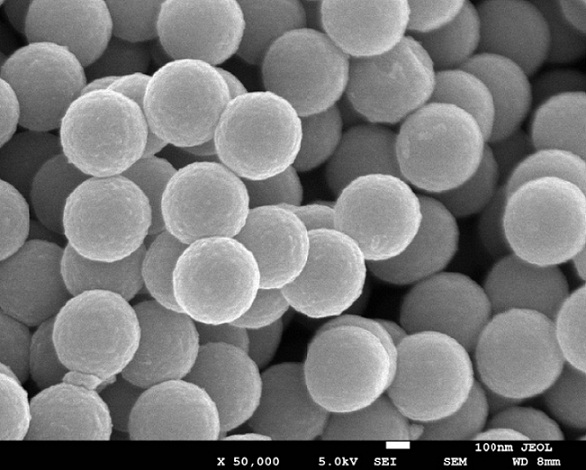

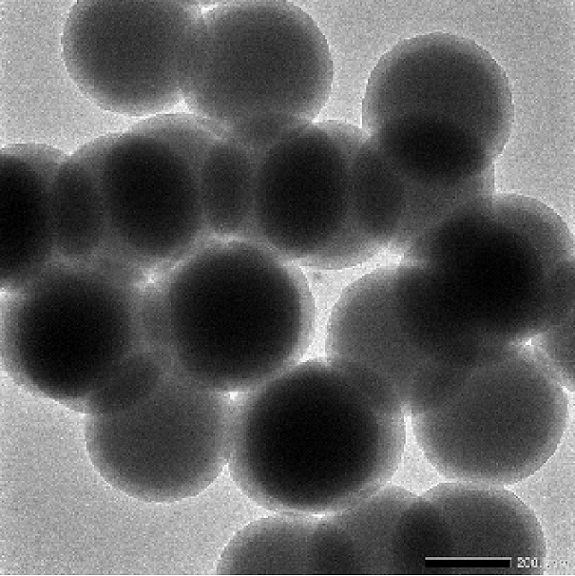

[0029] A kind of synthetic method of pomegranate silicon oxide-nitrogen-doped carbon composite material, comprises the steps:

[0030] Step a): Mix equal weights of lysine and water to obtain a lysine aqueous solution, and stir for 10 to 20 minutes. Then add a certain amount of tetrapropyl orthosilicate to the solution (aqueous solution of lysine: tetrapropyl orthosilicate = 100:2.5-5.7), and stir vigorously at room temperature for 30 minutes (1000-1500 rpm) , and continue to stir at 90°C at medium and low speed for 24h (300-500 rpm). Then slowly add a certain amount of tetrapropyl orthosilicate (2.5-3 times the amount of tetrapropyl orthosilicate added above). The mixture was kept at 90°C with medium-low speed continuous stirring (300-500 rpm) for 24 hours to obtain a silica-based dispersion.

[0031] Step b): Add a solution of 35–75 mmol melamine and 100–150 mmol formaldehyde (37wt%) in 10–40 ml of water and stir at 800–1000 rpm for 20–30 min at 85°C until a clear precurso...

Embodiment 1

[0038] A kind of synthetic method of pomegranate silicon oxide-nitrogen-doped carbon composite material, comprises the steps:

[0039] Step a): Mix equal weights of lysine and water to obtain a lysine aqueous solution, and stir for 10 minutes. Then add a certain amount of tetrapropyl orthosilicate to the solution (lysine aqueous solution: tetrapropyl orthosilicate = 100:2.5), stir vigorously at room temperature for 30 minutes (1000 rpm), and continue to stir at 90 Stir at medium and low speed for 24 hours at ℃ (300 rpm). Then slowly add a certain amount of tetrapropyl orthosilicate (2.5 times the amount of tetrapropyl orthosilicate added above). The mixture was kept at 90°C with medium-low speed continuous stirring (300 rpm) for 24 hours to obtain a silica-based dispersion.

[0040] Step b): Add 35mmol melamine and 100mmol formaldehyde (37wt%) solution in 10ml water, and stir at 800 rpm for 20 minutes at 85°C until a clear precursor solution is obtained.

[0041] Step c): C...

Embodiment 2

[0052] A kind of synthetic method of pomegranate silicon oxide-nitrogen-doped carbon composite material, comprises the steps:

[0053] Step a): Mix equal weights of lysine and water to obtain a lysine aqueous solution, and stir for 15 minutes. Add a certain amount of tetrapropyl orthosilicate to the solution (aqueous solution of lysine: tetrapropyl orthosilicate = 100:4), stir vigorously at room temperature for 30 minutes (1200 rpm), and then continue to stir at 90 Stir at medium and low speed for 24 hours at ℃ (400 rpm). Then slowly add a certain amount of tetrapropyl orthosilicate (2.5-3 times the amount of tetrapropyl orthosilicate added above). The mixture was kept at 90°C with medium-low speed continuous stirring (400 rpm) for 24 hours to obtain a silica-based dispersion.

[0054] Step b): A solution of 50 mmol melamine and 120 mmol formaldehyde (37 wt%) was added to 25 ml of water, and stirred at 900 rpm for 25 minutes at 85 °C until a clear precursor solution was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com