Magnetic multi-sensibilization sensor for aflatoxin as well as preparation and application of magnetic multi-sensibilization sensor

A technology of aflatoxin and sensor, which is applied in the field of grain, oil and food safety, can solve problems such as fastness, convenience, low cost, long time-consuming instrument detection methods, unfavorable on-site operation and use, etc., and achieves high adaptability to extreme conditions and a preparation method Mature and stable, weak toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

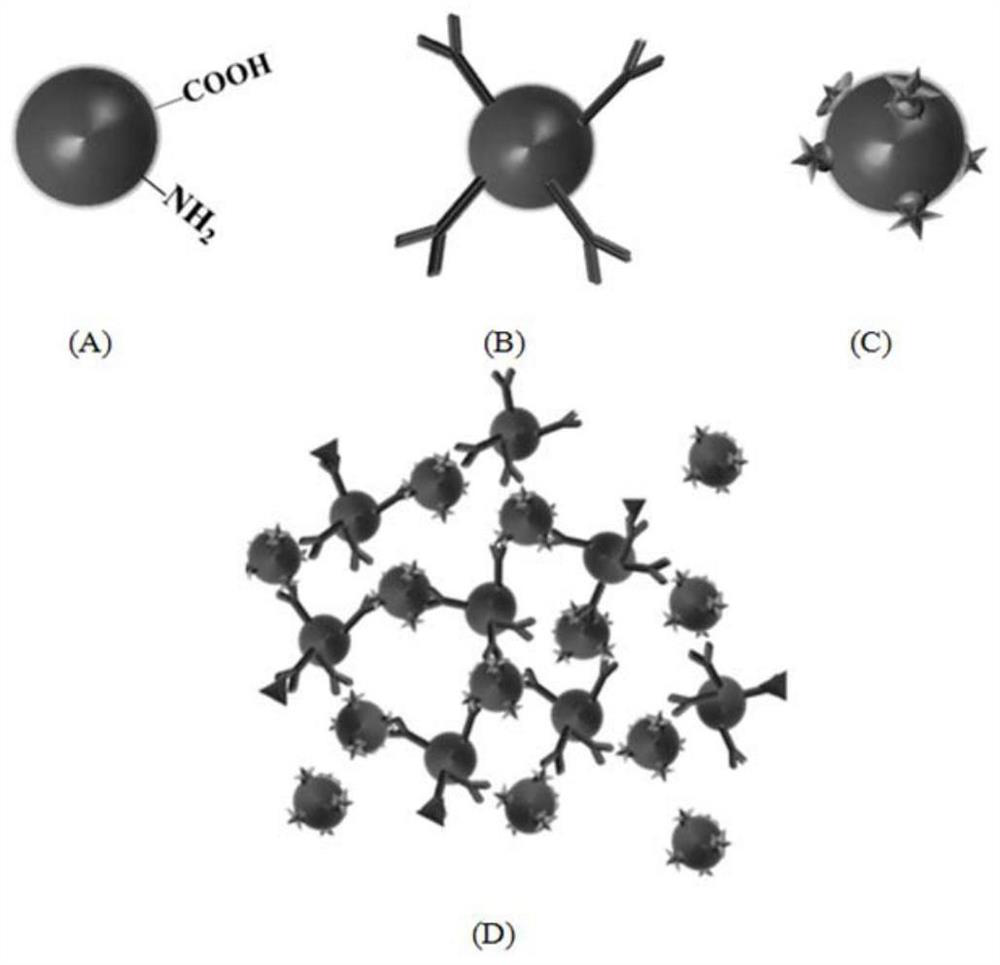

[0041] (1) His-Fe 3 o 4 Preparation of nanozymes

[0042] FeCl 3 ·6H 2 O was dissolved in ethylene glycol solution, stirred until the solution was transparent, and CH was added 3 COONa and histidine were stirred at 800-1200rpm. After 30min, the mixture was ultrasonicated for 10min, and then transferred to a polytetrafluoroethylene-lined stainless steel autoclave at 200-240°C for 12-16h. After the reaction was completed, the high-pressure The kettle was cooled to room temperature, washed several times with ethanol and dried at 60°C to obtain His-Fe nanoparticles with a size of 400-500 nm. 3 o 4 , namely His-Fe 3 o 4 nanozyme;

[0043] (2) Capture probe His-Fe 3 o 4 Preparation of @Ab

[0044] Antibodies and His-Fe 3 o 4 The histidine on the surface of the nanozyme is coupled by the activated ester method, the monoclonal antibody used is dissolved in phosphate buffer solution, and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt is added acid salt (EDC) and N-hyd...

Embodiment 1

[0060] A kind of preparation of aflatoxin magnetic multiple sensitization sensor, comprises the following steps:

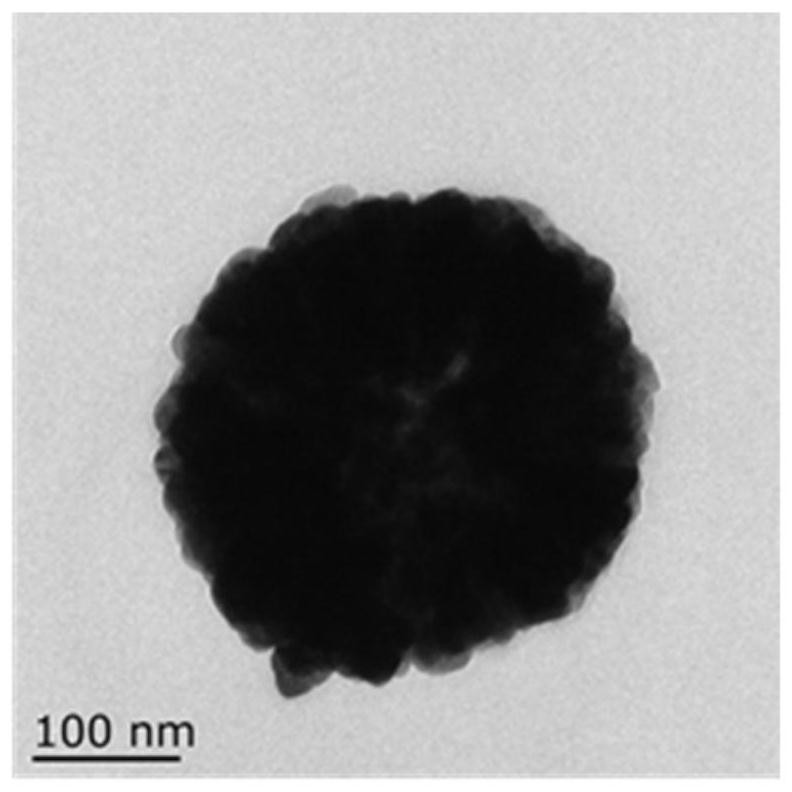

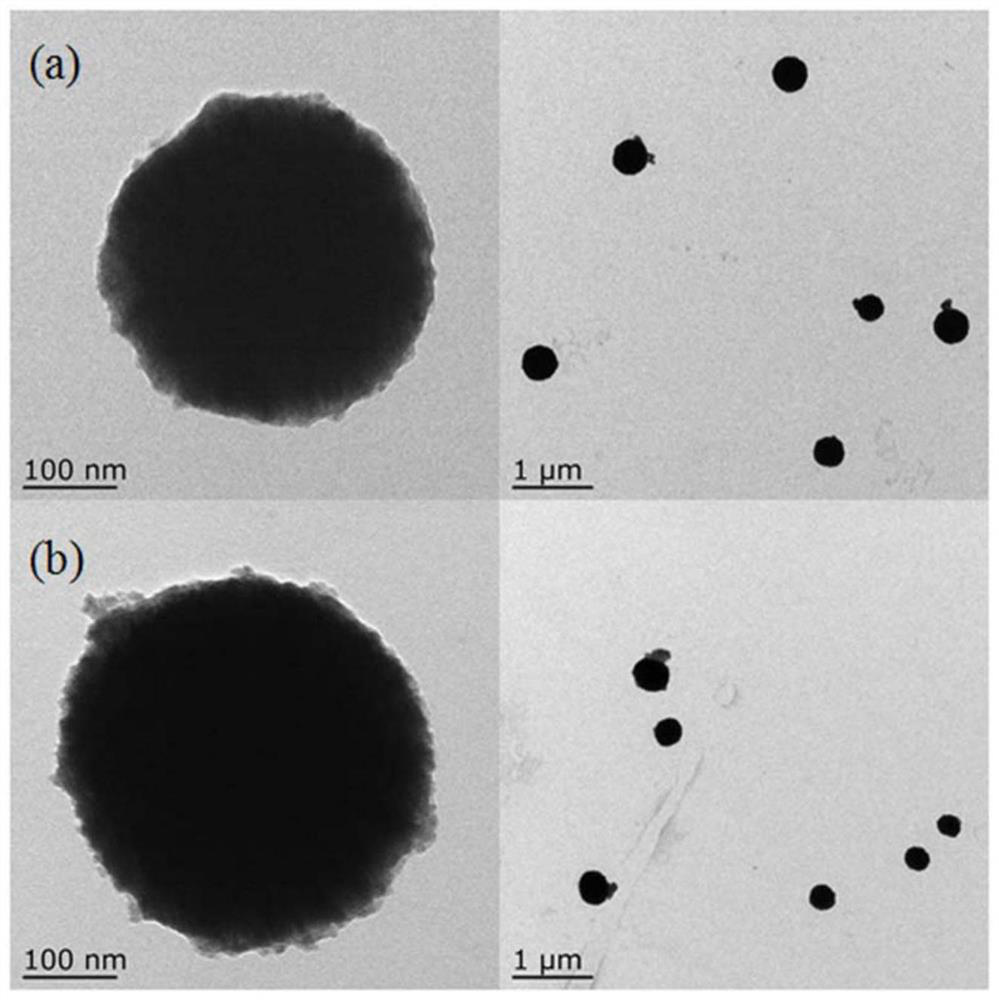

[0061] 1) His-Fe 3 o 4 Preparation of nanozymes:

[0062] 0.27g FeCl 3 ·6H 2 O was dissolved in 10 mL of ethylene glycol solution, and after the solution was clarified, 1.8 g of CH was added 3 Mix COONa and 0.5g histidine, keep stirring for 30min, then sonicate for 10min, react in a polytetrafluoroethylene-lined stainless steel autoclave at 200°C for 16 hours at high temperature, cool to room temperature, wash with ethanol 3 to 5 times, and dry at 60°C 12h, His-Fe with a size of 400-500nm can be synthesized 3 o 4 nanozyme;

[0063] 2) Capture probe His-Fe 3 o 4 @Ab's preparation:

[0064] Dissolve the monoclonal antibody used in phosphate buffer solution, add EDC and NHS for activation reaction, the ratio of the three is 1:40:40, respectively 28.3μmol, 1.132mmol and 1.132mmol, incubate at room temperature for 30min, ultrafilter Remove unreacted material...

Embodiment 2

[0070] Based on the application of the sensor prepared in Example 1 on aflatoxin B1 (AFB1) in food, the specific detection method is as follows:

[0071] There are seven groups of AFB1 standard solutions with different concentrations, the volume is 1.5mL, the concentrations are 0, 0.0001, 0.0005, 0.001, 0.005, 0.01, 0.05, 0.1, 0.5, 1ng / mL, add 0.4mL of capture probe, 25℃ Incubate at constant temperature and shake for 15 minutes, remove the supernatant of the complex constructed by magnetic separation, add 0.4 mL of detection probe, and incubate at 25°C for 15 minutes with constant temperature and shake, remove the supernatant to construct the spatial structure of magnetic separation, add 0.4 mL of chromogenic reagent, Incubate at 25°C with constant temperature and shaking for 5 minutes, magnetically separate and precipitate the spatial structure, measure the UV absorbance of the supernatant, and establish a standard curve between the absorbance and AFB1;

[0072] The prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com