Preparation method for preparing high-strength fracture-resistant concrete from waste materials

A concrete and high-strength technology, applied in the direction of clay preparation equipment, chemical instruments and methods, unloading equipment, etc., can solve the dead zone at the bottom of the residual concrete that does not consider the wear resistance of the mixer, does not consider the effect of recycling waste materials, and ignores raw materials Proportion dynamic control and other issues to achieve the effect of slowing down the evaporation rate of water, reducing the risk of cracking and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

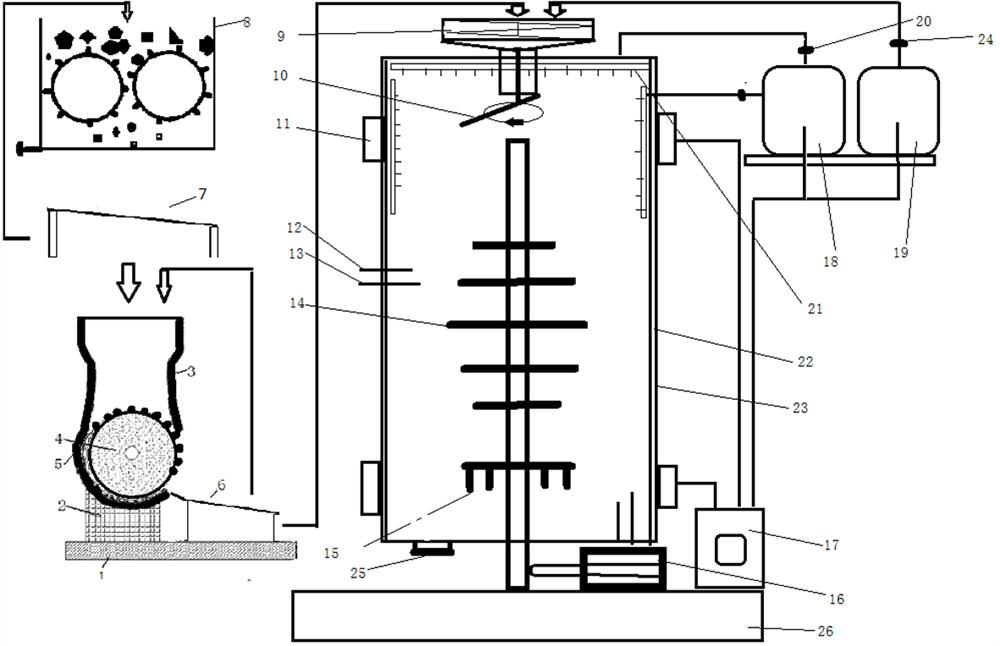

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing high-strength anti-fracture concrete from waste materials,

[0044] The raw materials are coarse aggregate, rapid hardening sulfoaluminate cement, modified waste residue, lime, sand, water reducer, early strength agent, thickener and modified polypropylene fiber; : Rapid hardening sulfoaluminate cement: Modified waste residue: Lime: Sand: Water reducer: Early strength agent: Thickener: Modified polypropylene fiber is 8:5:4:4:1:0.1:0.1:0.05 : 0.08;

[0045] The coarse aggregate is granite, bluestone, and dolomite mixed according to the mass ratio of 1:2:2, and the particle size obtained after crushing is 20mm;

[0046] The modified waste residue is to mix construction waste residue, coal gangue, and diatomite tailings according to the mass ratio of 1-5:2-3:2-4, crush and sieve, and then add alcohol amines and organic Acid, stirring treatment under heating conditions, and then drying treatment to obtain modified waste residue, the particle size of...

Embodiment 2

[0057] The difference from Example 1 is that in the raw materials, according to the mass ratio, coarse aggregate: rapid hardening sulphoaluminate cement: modified waste residue: lime: sand: water reducer: early strength agent: thickener: modified Polypropylene fiber is 8:5:5:4:1:0.1:0.1:0.05:0.1;

Embodiment 3

[0059] The difference from Example 1 is that in the raw materials, according to the mass ratio, coarse aggregate: rapid hardening sulphoaluminate cement: modified waste residue: lime: sand: water reducer: early strength agent: thickener: modified Polypropylene fiber is 8:5:2:4:1:0.1:0.1:0.05:0.05;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com