Vulcanized polymer composite material, positive pole piece containing vulcanized polymer composite material, and preparation method and application of vulcanized polymer composite material

A technology of composite materials and positive pole pieces, applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve the problems of affecting cycle life, battery capacity attenuation, and large specific surface area of vulcanized polymer materials, so as to improve cycle stability , reduce material agglomeration, reduce the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

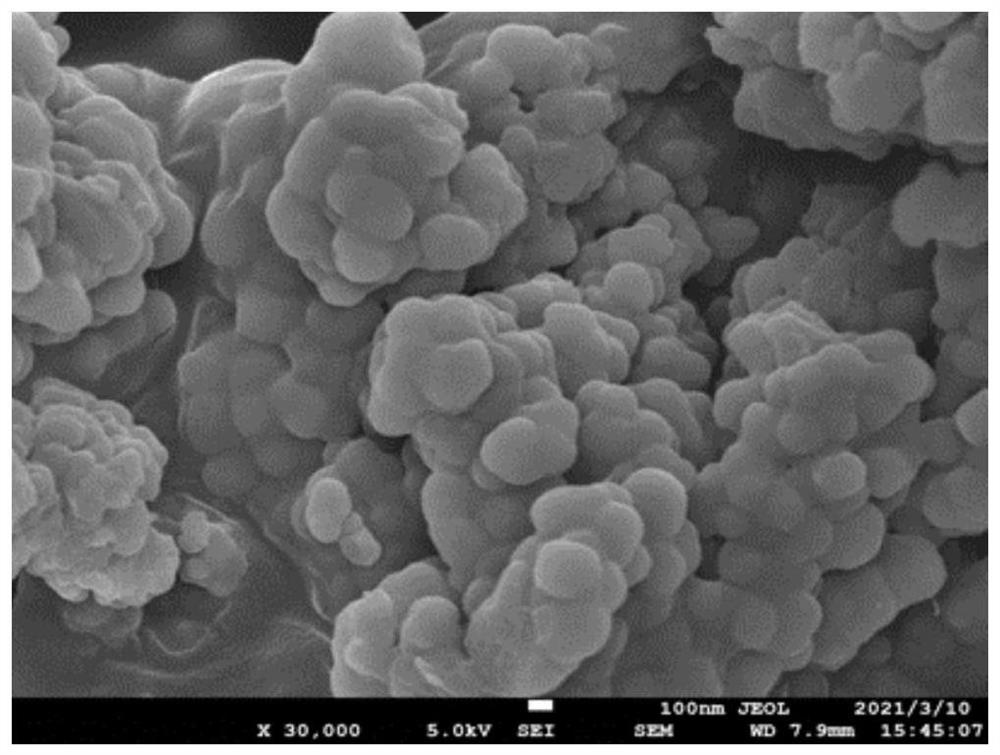

Image

Examples

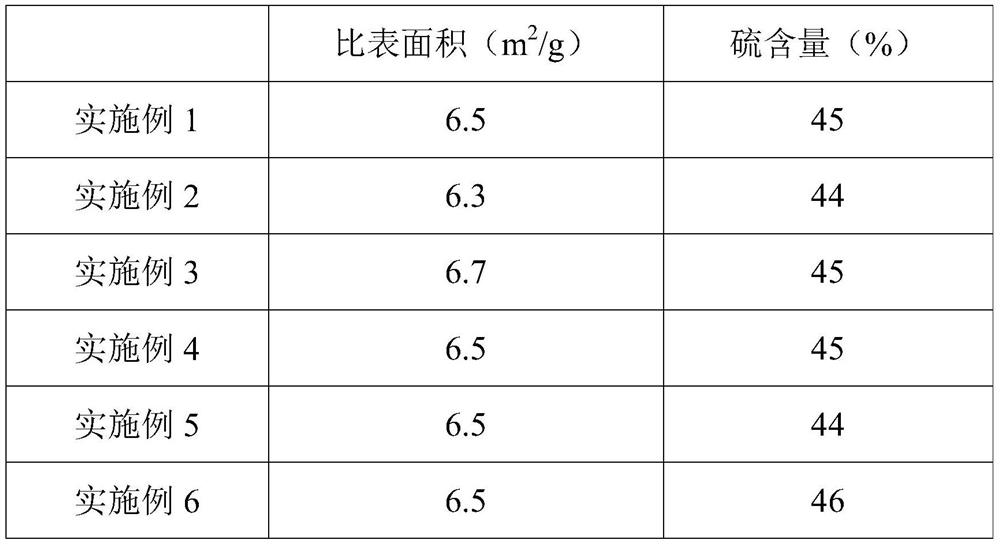

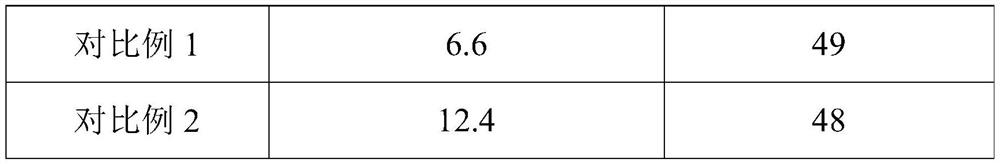

Embodiment 1

[0079] A preparation method of a vulcanized polymer composite material, specifically comprising the steps of:

[0080] (1) Sublimed sulfur and polyacrylonitrile (molecular weight: 150,000, molecular weight distribution index: 2.9) with a mass ratio of 3:1 are mixed by a ball mill for 1 hour at a rotating speed of 15 rpm to obtain a mixed powder;

[0081] (2) Fill the mixed powder obtained in step (1) into a graphite crucible, place it in a tubular furnace under the protective condition of a nitrogen flow rate of 0.5L / min, and heat it up to 300°C at a heating rate of 5°C / min. Prepared for 7 hours, heat treated at 550° C. for 3 hours to obtain the vulcanized polymer composite material.

Embodiment 2

[0083] A preparation method of a vulcanized polymer composite material, specifically comprising the steps of:

[0084] (1) mixing sublimated sulfur and polyacrylonitrile (molecular weight: 150,000, molecular weight distribution index: 2.9) with a mass ratio of 2:1 by a high-speed mixer for 2 hours at a rotating speed of 5 rpm to obtain a mixed powder;

[0085] (2) Fill the mixed powder obtained in step (1) into a ceramic crucible, place it in a muffle furnace under the protective condition of a nitrogen flow rate of 0.05L / min, and heat it up to 250°C at a heating rate of 3°C / min. Preparation for 10 hours, heat treatment at 450° C. for 5 hours to obtain the vulcanized polymer composite material.

Embodiment 3

[0087] A preparation method of a vulcanized polymer composite material, specifically comprising the steps of:

[0088] (1) Sublimed sulfur and polyaniline (molecular weight: 150,000, molecular weight distribution index: 2.9) with a mass ratio of 5:1 were mixed by a V-type mixer for 0.5h at a rotating speed of 25rpm to obtain a mixed powder;

[0089] (2) Fill the mixed powder obtained in step (1) into a quartz crucible, place it in a muffle furnace under the protective condition of a nitrogen flow rate of 1L / min, and heat it up to 450°C at a heating rate of 10°C / min for firing 3 hours, heat treatment at 600° C. for 3 hours to obtain the vulcanized polymer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com