Method for removing organic matters in shale gas wastewater

A technology for shale gas and organic matter, applied in water pollutants, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of complex process and poor removal of organic matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

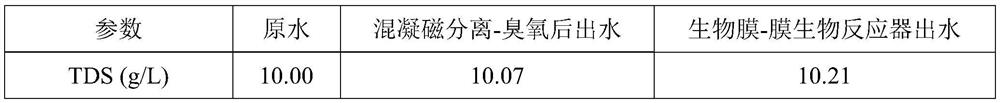

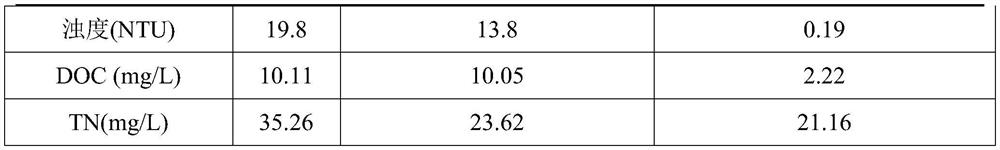

[0055] What embodiment adopts is Sichuan Weiyuan shale gas waste water, and concrete steps are as follows:

[0056] (1) Wastewater directly enters the coagulation sedimentation tank, the dosage of polyaluminum chloride is 100mg / L, and the dosage of polyacrylamide is 0.5mg / L; 200 rpm fast stirring for 2 minutes, 40 rpm slow speed Stir for 10 minutes and settle for 20 minutes.

[0057] (2) The effluent from step (1) enters the ozone oxidation tank for further treatment, the ozone dosage is 100 mg / L, and the reaction time is 60 minutes.

[0058] (3) The effluent from step (2) enters the biofilm-membrane bioreactor device for further treatment. The type of carrier in the reactor is a polyurethane square with a side length of 1cm, the filling rate is 20%, DO is controlled at 4-6mg / L, hydraulic The residence time is 48 hours, and the solid residence time is 30 days. The ultrafiltration membrane is polyvinylidene fluoride (PVDF) hollow fiber membrane, and the ultrafiltration flux is...

Embodiment 2

[0063] What embodiment adopts is Sichuan Weiyuan shale gas waste water, and concrete steps are as follows:

[0064] (1) Wastewater directly enters the coagulation sedimentation tank, the dosage of polyferric chloride is 40mg / L, and the dosage of polyacrylamide is 0.1mg / L; 200 rpm fast stirring for 2 minutes, 30 rpm slow speed Stir for 10 minutes and settle for 10 minutes.

[0065] (2) The effluent from step (1) enters the ozone oxidation tank for further treatment, the ozone dosage is 150 mg / L, and the reaction time is 60 minutes.

[0066] (3) The effluent from step (2) enters the biofilm-membrane bioreactor device for further treatment. The carrier type in the reactor is a polystyrene block with a side length of 1 cm, the filling rate is 40%, and DO is controlled at 4-6 mg / L , The hydraulic retention time is 12 hours, the solid retention time is 12 days, the ultrafiltration membrane is a polyvinylidene fluoride (PVDF) hollow fiber membrane, and the ultrafiltration flux is 30...

Embodiment 3

[0072] What embodiment adopts is Sichuan Weiyuan shale gas waste water, and concrete steps are as follows:

[0073] (1) Waste water directly enters the coagulation sedimentation tank, the dosage of polyferric chloride is 300mg / L, and the dosage of polyacrylamide is 1mg / L; 200 rpm fast stirring for 2 minutes, 40 rpm slow stirring 10 minutes, precipitation 20 minutes.

[0074] (2) The effluent from step (1) enters the ozone oxidation tank for further treatment, the ozone dosage is 200 mg / L, and the reaction time is 60 minutes.

[0075] (3) The effluent from step (2) enters the biofilm-membrane bioreactor device for further treatment. The carrier type in the reactor is a polyvinyl chloride square with a side length of 1cm, the filling rate is 15%, and DO is controlled at 4-6mg / L , The hydraulic retention time is 24 hours, the solid retention time is 15 days, the ultrafiltration membrane is a polyvinylidene fluoride (PVDF) hollow fiber membrane, and the ultrafiltration flux is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com